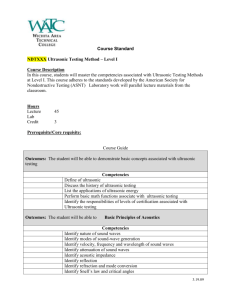

ULTRA S TEST

advertisement

INSPECTION OF CASTINGS SEVERAL METHODS VISUAL OPTICAL - FOR SURFACE DEFECTS SUBSURFACE AND INTERNAL DEFECTS THROUGH NDTs & DTs PRESSURE TIGHTNESS OF VALVES BY SEALING THE OPENING AND PRESSURISING WITH WATER CASTING DEFECTS SURFACE METALLIC PROJECTION (4) DEFECTIVE SURFACE (11) CHANGE IN DIMENSION- WARP INCOMPLETE CASTING MISRUN, RUNOUT CAVITYBLOWHOLES, SHRINKAGE PINHOLES DISCONTINUITY HOT CRACK COLD SHUT, COLD CRACK SUBSURFACE SUBSURFACE CAVITY INCLUSIONS DISCONTINUITY NDTs Methods of testing DestructiveNon destructiveRadiagraphic Ultrasonic Non Destructive Testing with Ultrasonics for flaw Detection in Castings, Weldments, Rails, Forged Components etc. ULTRASONIC TESTING Why Ultrasonics ? ……… Flaw detection in metals and nonmetals Flaw measurement in very thick materials Internal and surface flaws can be detected Inspection costs are relatively low. Rapid testing capabilities and portability. Ultrasonic waves are simply vibrational waves having a frequency higher than the hearing range of the normal human ear, which is typically considered to be 20,000 cycles per second (Hz). The upper end of the range is not well defined. Frequencies higher than 10 GHz have been generated. However, most practical ultrasonic flaw detection is accomplished with frequencies from 200 kHz to 20 MHz, with 50 MHz used in material property investigations. Ultrasonic energy can be used in materials and structures for flaw detection and material property determinations. Ultrasonic waves are mechanical waves (in contrast to, for example, light or xrays, which are electromagnetic waves) that consist of oscillations or vibrations of the atomic or molecular particles of a substance about the equilibrium positions of these particles. Ultrasonic waves behave essentially the same as audible sound waves. They can propagate in an elastic medium, which can be solid, liquid, or gaseous, but not in a vacuum. In solids, the particles can (a) oscillate along the direction of sound propagation as longitudinal waves, or (b) the oscillations can be perpendicular to the direction of sound waves as transverse waves. At surfaces and interfaces, various types of elliptical or complex vibrations of the particles occur. THEORY OF TESTING MACHINE SPECIFICATIONS Make: Weight: Calibration range upto 9999 mm. Choice of Frequency range Provision for adjusting gain. Documentation possibility via printer Limitation:……………. Probe SCANNING TECHNIQUES Pulse Echo method Straight beam method Angle beam method PULSE ECHO METHOD Inspection of: Gas porosity Slag Entrapment Cracks With the exception of single gas pores all the defects listed are usually well detectable by ultrasonics. Ultrasonic flaw detection has long been the preferred method for nondestructive testing , mainly in welding applications. This safe, accurate and simple technique has pushed ultrasonics to the forefront of inspection technology. The proper scanning area for the weld: First calculate the location of the sound beam in the test material. Using the refracted angle, beam index point and material thickness, the V-path and skip distance of the sound beam is found. Then identify the transducer locations on the surface of the material corresponding to the crown, sidewall, and root of the weld. Inspectionof Rails New trend: Ultrasonic Simulation - UTSIM UTSIM is a user interface integrating a CAD model representing a part under inspection and an ultrasound beam model. Ultrasonic sizing of small flaws with the distance-amplitude-correction (dac) curve