PROJECTS WITH POTENTIAL FUNDING 2

advertisement

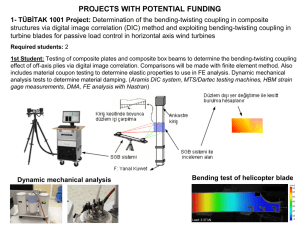

PROJECTS WITH POTENTIAL FUNDING 1- TÜBİTAK 1001 Project: Determination of the bending-twisting coupling in composite structures via digital image correlation (DIC) method and exploiting bending-twisting coupling in turbine blades for passive load control in horizontal axis wind turbines Required students: 2 1st Student: Testing of composite plates and composite box beams to determine the bending-twisting coupling effect of off-axis plies via digital image correlation. Comparisons will be made with finite element method. Also includes material coupon testing to determine elastic properties to use in FE analysis. Dynamic mechanical analysis tests to determine material damping. (Aramis DIC system, MTS/Dartec testing machines, HBM strain gage measurements, DMA, FE analysis with Nastran) Dynamic mechanical analysis Bending test of helicopter blade PROJECTS WITH POTENTIAL FUNDING 2nd Student: Design of a reference wind turbine blade to be used in multi-body simulations of the wind turbine system. Multi-body transient aeroelastic analysis of wind turbine system to study the effect of bending-twisting coupling induced on the composite blades on the load alleviation in the wind turbine system. (PreVabs-Vabs beam section analysis codes, Samcef Wind Turbine/Focus wind turbine system multi body analysis codes, Samcef and Nastran FE codes) Moment at Blade-hub connection PROJECTS WITH POTENTIAL FUNDING 2- SANTEZ PROJECT with Dr. Gürses, Dr. Çoker and TEI Development of advanced bolted flange design and analysis tool Required students: 1 ( 2 more for Dr. Gürses and Dr. Çoker) Evaluation of finite element and test results on friction, contact and bolt torque - preload and design a bolted flange design and analysis tool interface (ANSYS FE code) Input: Flange type, geometry (geometric tolerances, surface roughness etc.) number of bolts (type, preloadtorque relation), friction coefficient, material, loads(thermal, axial, shear force, bending moment, torque, working conditions (dry, with oil, temperature), fatigue loads Output: Strength (flange and bolt), life, separation and slippage Different flange types seen in gas turbines OTHER THESIS TOPICS 1- Generation of finite element model of a manufactured wind turbine blade, finite element analysis and static tests by DIC and strain gage system 2- Analytical and finite element approach for material characterization of woven composites 3- Development of a static aeroelastic analysis tool based on beam finite element and linear aerodynamics 4- Structural analysis and optimization of composite structures (straight and curved laminates with cut-outs) manufactured by fiber/tow placement machines 5- Aeroelastic stability analysis of wing-body combinations with control surfaces and external stores 6- Progressive failure analysis of composite structures via micromechanics of failure (MMF) methodologies under geometrically nonlinear deformations 7- Investigation of the effect of damage progression on the aeroelastic stability of composite wings 8- Investigation of the effect of damage progression on the transient aeroelastic response of wind turbine blades 9- Development of a beam cross-sectional analysis tool for composite beams that simulate helicopter blades or wind turbine blades 10- Investigation of damping characteristics of fiber reinforced composites with carbon nanotube enhanced epoxy resin 11- Development of a structural sizing tool for the conceptual design phase of aircraft structures