DYEING OF COTTON WITH VAT DYES

advertisement

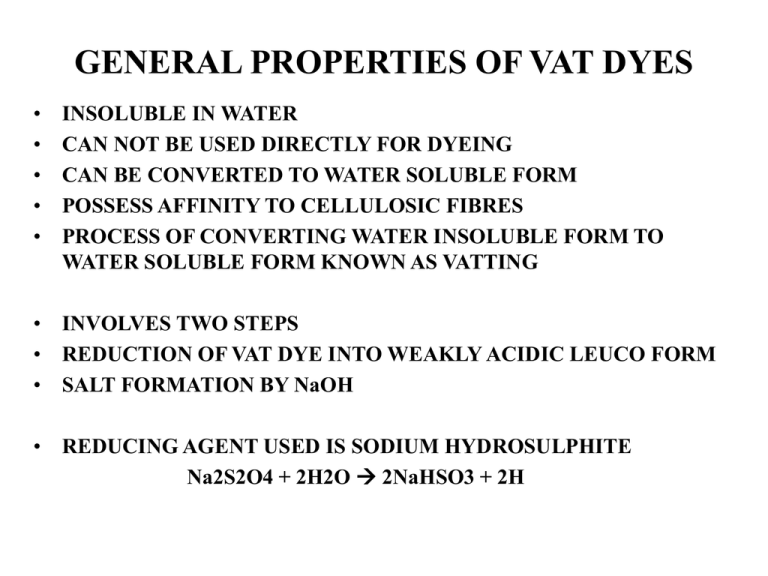

GENERAL PROPERTIES OF VAT DYES • • • • • INSOLUBLE IN WATER CAN NOT BE USED DIRECTLY FOR DYEING CAN BE CONVERTED TO WATER SOLUBLE FORM POSSESS AFFINITY TO CELLULOSIC FIBRES PROCESS OF CONVERTING WATER INSOLUBLE FORM TO WATER SOLUBLE FORM KNOWN AS VATTING • INVOLVES TWO STEPS • REDUCTION OF VAT DYE INTO WEAKLY ACIDIC LEUCO FORM • SALT FORMATION BY NaOH • REDUCING AGENT USED IS SODIUM HYDROSULPHITE Na2S2O4 + 2H2O 2NaHSO3 + 2H DYEING OF COTTON WITH VAT DYES PRINCIPLE • CONVERSION OF WATER INSOLUBLE VAT DYE INTO ITS SOLUBLE FORM • DYEING OF COTTON • RECONVERSION OF SOLUBLE VAT DYE ON FIBRE INTO PARENT INSOLUBLE FORM • INDIGO IS ONE OF THE OLDEST NATURAL VAT DYE • SYNTHETIC INDIGO AND OTHER VAT DYES ARE MANUFACTURED SINCE EALY 1900’S CHEMICAL CLASSIFICATION OF VAT DYES • TWO MAIN CLASSES • INDIGOID VAT DYES: DERIVATIVES OF INDIGO OR THIO-INDIGO ANTHRQUININE VAT DYES REDUCTION OF VAT DYE REDUCTION OF VAT DYE • REDUCING PROPERTY OF SODIUM HYDROSULPHITE Na2S2O4 + 2H2O 2 NaHSO3 + 2H REDUCTION OF INDIGO REDUCTION OF VAT DYE AMOUNT OF Na2S2O4 AND NaOH • STOICHIOMETRICALLY 1 MOLE OF Na2S2O4 AND 2 MOLES OF NaOH ARE CONSUMED PER ANTHRAQUINONE RING IN DYE MOLECULE • IN PRACTCE GREATER AMOUNT OF Na2S2O4 AND NaOH IS USED • DECOMPOSITION OF Na2S2O4 BY ATMOSPHERIC OXYGEN AND DISSOLVED OXYGEN IN WATER AND ENTRAPPED IN FIBRE • NEUTRALIZATION OF NaOH BY ACIDIC DECOMPOSITION PRODUCTS OF Na2S2O4 Na2S2O4 + 2H2O 2NaHSO3 + 2H NaHSO3 + NaOH Na2SO3 + 2H2O • DISSOLVED CO2 IN WATER ALSO CONSUMES SOME ALKALI • IN PRACTICE AMOUNT OF Na2S2O4 USED IS 2-3 TIMES HIGHER • AMOUNT OF NaOH USED IS 1.5-2 TIMES HIGHER THAN NEEDED STOICHIOMETRICALLY STEPS IN VAT DYEING 1. FOUR STEPS REDUCTION: CONVERSION OF INSOLUBLE FORM TO ITS SOLUBLE FORM IN PRESENCE OF STRONG REDUCING AGENT AND CAUSTIC SODA (LEUCO VAT DYE) 2. DYEING: DYEING OF COTTON WITH LEUCO VAT DYE 3. OXIDATION: OXIDATION OF VAT DYE INSIDE THE FIBRE INTO WATER INSOLUBLE FORM (OXIDATION) 4. SOAPING: SUBSEQUENT TREATMENT OF DYED MATERIAL WITH HOT WASHING LIQUOR CONTAINING ANIONIC DETERGENT TO OBTAIN BRIGHT SHADES, DYE AGGREGATION AND EXTREMELY GOOD FASTNESS PROPERTIES CLASSIFICATION ACCORDING TO APPLICATION 1. 2. 3. 4. • • • FOUR GROUPS ACCORDING TO VATTING AND DYEING CONDITIONS IK IW IN IN SPECIAL DYEING STEPS PREPARATION OF STOCK VAT DYEING THE CONDITIONS OF DYEING DEPENDS ON VAT DYE CLASS USED RECIPE FOR STOCK VAT CLASS DYE QTY kg Iw 1 In 1 In special 1 CAUSTIC SODA (32.5%) litre 1.5 Na2S2O4 water kg litre Temp. Time 0C min. 0.5 50 50 10 3.0 0.75 50 60 10 6.0 1.50 100 60 10 DYE BATH ADDITIONS Process Additions Iw 1:20 1:10 1:5 In 1:20 1:10 1:5 In special 1:20 1:10 NaOH ml/l 8-10 12-15 18-23 15-20 22-26 32-40 22-26 32.5% 3-4 NaCl g/l 15-25 15-20 15-20 ------------------------------------------------------- 45-50 8-12 3.5-4.5 5.5-8 9.5-13 3.5-4.5 5.5-8 48-58 Hydro g/l Dyeing Temp. 0 c 5-6.5 32-38 1:5 50-60 50-60 9.5-13.5 DYEING AUXILIARIES REDUCING AGENT • SODIUM HYDROSULPHITE OR SODIUM DITHIONATE SENSITIVITY • • • • • • • HYDRO IS SENSITIVE TO ATMOSPHERIC OXYGEN DECOPOSES DURING VATTING AND DYEING OF VAT DYE EXCESS MUST ALWAYS BE PRESENT DECOPOSITION INCREASES WITH TEMPERATURE AGITATION OF DYE LIQUOR EXPOSED SURFACE AREA OF DYE BATH HYDROSULPHITE DECOMPOSITION • NEUTRAL MEDIUM 2Na2S2O4 + H2O Na2S2O3 + 2NaHSO3 • ALKALINE MEDIUM 2Na2S2O4 + 2NaOH Na2S2O3 + 2Na2SO3 +H2O • REACTOION WITH ATMOSPHERIC OXYGEN (ALKALINE MEDIUM) Na2S2O4 + 2NaOH +O2 Na2SO3 + Na2SO4 +H2O DYEING AUXILIARIES ALKALI • • • • • • • • • • • MAINTAIN REDUCED DYE IN WATER SOLUBLE FORM ALKALI ALSO CONSUMED DURING DYEING BY DYE, REACTION WITH HYDROSULPHITE, AND ATMOSPHERIC OXYGEN, EXCESS MUST BE PRESENT TEST HYDRO: VAT PAPER, YELLOW PAPER TURNS BLUE ALKALI: PHENOLPHTHALEIN PAPER, WHITE PAPER TURNS PINK ELECTROLYTE MOST COMMON NaCL OR Na2SO4 OTHER AUXILIARIES WETTING AGENT HELPS IN WETTING OF FABRIC DURING DYEING, ASSIST DYE PENETRATION ANIONIC DETERGENT USED DURING SOAPING, FACILITATES REMOVAL OF SURFACE DYE, DYE AGGREGATION INSIDE FIBRE DEVELOP TRUE SHADE AND GOOD FASTNESS PROPERTIES DYEING OF COTTON FABRIC EXHAUST DYEING JIGGER IS THE MOST COMMONLY USED MACHINE FOR EXHAUST DYEING STEP 1 VATTING: CONVERSION OF INSOLUBLE FORM TO SOLUBLE FORM STOCK VAT: REDUCTION IN STRONG CONCENTRATION. CHEMICAL REACTION INCREASES WITH CONCENTRATION VAT DYE X PARTS HYDRO 2 X PARTS CAUSTIC SODA 1 X PARTS WATER 50 X PARTS TEMPERATURE 50-60OC TIME 10-15 MIN. TEST FOR VATTING: SPOT VATTED DYE SOLUTION ON FILTER PAPER. SPREADING OF SPOT WITHOUT DEPOSITION OF INSOLUBLE DYE PARTICLES EXHAUST DYEING BLANK DYE BATH CAUSTIC SODA HYDRO DYEING • • • • • • • • • 20 g/l 15 g/l LOAD THE FABRIC UNIFORMLY WITHOUT CREASES ONTO ONE OF THE ROLLER OF JIGGER BY PASSAGE THROUGH PLAIN WATER RUN THE FABRIC (2 ENDS) THROUGH BLANK BATH AT ROOM TEMP. ADD HALF THE QUANTITY OF STOCK VAT RUN FOR 2 ENDS ADD THE REMAINING STOCK VAT RAISE TEMP SLOWLY TO 60OC CONTINUE DYEING FOR 45 MIN (8-10 ENDS) AFTER EACH END CHECK FOR PRESENCE OF HYDRO WITH VAT PAPER (DYED WITH NAVINON YELLOW 5G) COLOUR CHANGE YELLOW TO BLUE AND ALKALI WITH PHEOLPHTHALEIN PAPER. COLOUR CHANGE COLOURLESS TO PINK. IF FOUND INSUFFICIENT PREDISSOLVE AND ADD TO JIGGER WHILE STATIONARY. OXIDATION • AFTER DYEING DRAIN THE DYEBATH • RINSE THE FABRIC THROUGH COLD WATER (2ENDS) TO REMOVE LOOSE DYE AND EXCESS HYDRO AND ALKALI • CONVERT THE LEUCO VAT DYE TO ITS ORIGINAL OXIDIZED FORM BY TEATMENT WITH 2 g/l H2O2 AT 40-50OC (4 ENDS) • RINSE WITH COLD WATER • SOAPING: ABSOLUTELY ESSENTIAL FOR DEVELOPMENT OF TRUE SHADE AND BEST FASTNESS PROPERTIES. • REMOVAL OF SURFACE DYE AND AGGREGATION OF DYE INSIDE THE FIBRE • SOAP AT BOIL USING 2 g/l LISSAPOL D (ANIONIC DETERGENT) AND 2 g/l SODA ASH (4 ENDS) • RINSE WITH COLD WATER (2 ENDS) • UNLOAD FROM JIGGER • DRY SEMI-CONTINUOUS DYEING • MANY VAT DYES HAVE STRONG AFFINITY FOR COTTON • PENETRATION IN CLOSELY WOVEN FABRIC IS DIFFICULT • SEMICONTINUOUS OR CONTINUOUS METHODS USED • PIGMENT PAD-DEVELOPMEMNT ON JIGGER • • • • • PAD WITH VAT DYE DISPERSION DRY DEVELOP ON JIGGER USING HYDRO AND CAUSTIC SODA OXIDIZE AND SOAP IN JIGGER THE METHOD IS USED FOR DYEING TIGHTLY WOVEN FABRIC LIKE SUITING. SEMI-CONTINUOUS METHOD PAD-JIG METHOD • PREPARATION OF DYE DISPERSION: • USE ONLY ULTRA FINE VAT DYES • STIR THE VAT DYE POWDER IN 10-20 TIMES ITS WEIGHT OF WATER AT 500C WITH HIGH SPEED STIRRING • FILTER THE DISPERSION • MAKE THE TOTAL VOLUME • ADD WETTING AGENT OR LEVELLING AGENT. • READY FOR PADDING. • PADDING • • • • • • • PADDING USE WELL SCOURED BLEACHED FABRIC IN DRY STATE GOOD WETTING OF FABRIC IS ESSENTIAL SATURATE THE FABRIC WITH DYE DISPERSION SQUEEZE OUT EXCESS LIQUOR (EXPRESSION 70%) PADDING MANGLE SPEED 20 M/min. IF FABRIC IS TOO TIGHT CONSTRUCTION, PAD AT HIGH TEMP (60-700C) • • • • DRYING DEVELOPMENT MAY BE DONE IN WET STATE OR AFTER DYRYING IF WET, DEVELOP WITHOUT DELAY UNIORM DRYING OF PADDED FABRIC ALONG THE WIDTH AND BACK AND FACE OF FABRIC IS ESSENTIAL MACHINE USED EITHER HOT FLUE OR STENTER HOT CYLINDER DRYING IS NOT ADVISABLE DUE TO BACK TO FACE DYE MIGRATION. • • DEVELOPMENT ON JIGGER • SET THE JIGGER BATH WITH REQUIRED AMOUNTS OF HYDRO AND CAUSTIC SODA. • ADD SMALL QUANTITY OF PADDING LIQUOR TO THE BLANK BATH IN JIGGER TO COMPENSATE FOR THE DYE WHICH BLEEDS OUT FROM FABRIC • THE DEVELOPMENT IS SIMILAR TO JIGGER DYEING OPERATION FOLLOWED BY OXIDATION AND SOAPING TREATMENT. CONTINUOUS METHOD • • PAD-STEAM PROCESS • PRINCIPLE: INCREASE IN RATE OF DYEING WITH INCREASE IN TEPERATURE. • DYE REDUCTION ON FABRIC SURFACE • IMMEDIATE DYE ADSORPTION • PIGMENT PAD DRY CHEMICAL PAD (CAUSTIC SODA, HYDRO, COMMON SALT) STEAM (30-60 SEC.) RINSE OXIDIZE SOAP -> RINSE (8 COMPRTMENT OPEN SOAPER) DRY CHEMICAL PADDING • AFTER PIGMENT PADDING AND DRYING, COOL THE FABRIC TO AVOID DYE REDUCTION IN CHEMICAL PAD TROUGH • PAD THE FABRIC WITH SOLUTION OF HYDRO AND CAUSTIC SODA (CHEMICAL PAD LIQUOR) • THE CONCENTRATION OF HYDRO AND CAUSTIC SODA DEPENDS ON CONCENTRATION OF DYE ON FABRIC. • DYE CONC. ON FABRIC NaOH/Na2S2O4 g/kg g/l 10 25-30 30 35-50 50 50-70 • 5-10 LITRES OF PIGMENT DISPERSION/100 LITRE OF CHEMICAL LIQUOR ARE ADDED TO THE BATH STEAMING • CHEMICAL PADDED FABRIC IN WET CONDITION IMMEDIATELY PASSED INTO STEAMER • STEAM FOR 20-30 SEC. IN SATURATED AIR FREE STEAM AFTER TREATMENT • THE FINAL TREATMENTS INVOLVING OXIDATION AND SOAPING ON 8 COMPARTMENT OPEN SOAPER • METHOD IS SUITABLE ONLY FOR PALE TO MEDIUM DEPTH OF SHADES • THE STEAMER SHOULD BE SITUATED AS CLOSE AS POSSIBLE TO CHEMICAL PADDING MANGLE, TO MINIMIZE HYDRO DECOPOSITION IN AIR BEFORE STEAMING. CONTINUOUS METHOD DYEING OF COTTON WITH INDIGO • INDIGO HAS POOR AFFINITY TOWARDS COTTON • CONVENTIONAL EXHAUST OR CONTINUOUS METHODS ARE NOT SUITABLE • SPECIAL METHOD OF MULTIPLE DIP AND NIP (5 DIP AND 5 NIP) METHOD IS USED IN COMMERCIAL PRACTICE • MAJOR APPLICATION FOR DYEING OF COTTON WARP FOR PRODUCTION OF STONE WASH DENIM/JEAN FABRIC INDIGO DYEING • STOCK VAT INDIGO CAUSTIC SODA HYDRO TEMP. TIME X g/l X g/l Xg/l 60OC 15 MIN. DYEBATH INDIGO 3 g/l CAUSTIC SODA 2 g/l HYDRO 1.5 g/l WETTING AGENT 1 g/l DYEING TEMP. ROOM TEMP. INDIGO DYEING • CONTINUOUS DYEING RANGE • TROTMAN P453 SOLUBILIZED VAT DYES • DISULPHURIC ESTERS OF INDIGO OR AQ VAT DYES • • • • • • LEUCO VAT DYE OBTAINED BY TREATMENT OF VAT DYE WITH HYDRO TREAT LEUCO VAT DYE WITH CHLOROSULPHONIC ACID (ClSO3H) IN PRESENCE OF PYRIDINE AT 60-700C TREAT THE PRODUCT WITH SLIGHT EXCESS OF Na2CO3 OR NaOH REMOVE PYRIDINE BY STEAM DISTILLATION CONCENTRATE TO CRYSTALLIZE OR SALT OUT WITH NaCl GENERAL PROPERTIES • • • • • • • • • SOLUBILITY LOW SOLUBILITY, 50 g/l AT 50-600C SOLUBILITY RANGE IS SUFFICIENT USED FOR DYEING PALE SHADES DO NOT DISSOLVE IN BOILING WATER: PREMATURE DYE OXIDATION LIGHT SENSITIVITY SENSITIVE TO SLIGHT IN POWDER AS WELL IN SOLUTION FORM. PREMATURE OXIDATION TO INSOLUBLE VAT DYE EXPOSURE TO LIGHT SHOULD BE AVOIDED ACTION OF LIGHT CAN BE MINIMIZED BY ADDING SMALL QUANTITY OF SODA ASH TO DYE SOLUTION GENERAL PROPERTIES • SUBSATNTIVITY • LOW AFFINITY TO COTTON • GOOD LEVELLING AND PENETRATION ON TIGHTLY WOVEN FABRIC • STANDING BATH MAY BE USED • DYEBATH IS REPLENISHED AFTER DYEING ONE LOT BY DYE CONCENTRATION EQUIVALENT TO THAT TAKEN BY FABRIC • EXCELLENT REPRODUCIBILITY OF SHADES • ADDITION COMMON SALT IMPROVES DYE EXHAUSTION • DYEING MAY BE CARRIED OUT AT ROOM TEMPERATURE. • OXIDATION • CARRIED OUT UNDER ACIDIC CONDITIONS • H2SO4 + NaNO2, NaNO2 + HCOOH, K2Cr2O7 + H2SO4 ARE COMMONLY USED APPLICATION • 1. 2. 3. THREE STEPS PADDING OR EXHAUSTION OF DYE FROM SLIGHTLY ALKALINE OR NEUTRAL SOLUTION DEVELOPMENT ON FABRIC IN PRESENCE OF OXIDIZING AGENT NaNO2 + H2SO4 (MOST COMMON) AT ROOM TEMP OR 50-600C OR EVEN HIGHER DEPENDING ON EASE OF DYE OXIDATION AFTER TREATMENT: NEUTRALIZATION, AND SOAPING, RINSING DYEING METHODS • • EXHAUST METHOD (JIGGER DYEING) PAD-DEVELOP METHOD • • • • • • • • • JIGGER DYEING SET DYE BATH WITH 0.5 g/l SODA ASH AND 5-10 g/l NaNO2 DYEING TEMP. ROOM TEMP – 400C ADD HALF THE QUANTITY OF DISSOLVED DYESTUFF, GIVE ONE END ADD SECOND REMAINGING DYESTUFF, GIVE ONE END ADD 10-40 g/l SALT OVER TWO ENDS EXCESS SALT CONC. PRECIPITTES THE DYE COMPLETE DYEING IN 4-6 ENDS DEVELOP THE BATCH ON TO ANOTHER JIGGER IF STANDING BATH IS TO BE USED. RUN TWO ENDS THROUGH H2SO4 BATH AT 50-600C RINSE, SOAP AT BOIL, RINSE • • CONTINUOUS DYEING • LOW AFFINITY. MOST SUITED FOR CONTINUOUS DYEING • TYPICAL PAD LIQUOR COMPOSITION DYE X g/l, Na2CO3 1 g/l, NON-IONIC WETTING AGENT 1 g/l, NaNO2 10 g/l • PAD AT ROOM TEMPERATURE • DEVELOP IN A BATH CONTAINING 10 g/l NaNO2 AND 10 g/l H2SO4 AT 600 C IN THE 1st COMPARTMENT OF THE 8 COMPARTMENT OPEN SOAPER • SOMETIMES THE PADDED FABRIC IS DRIED BEFORE DEVELOPMENT • INTERMEDIATE DRYING GIVES BETTER COLOUR YIELD • AFTER ACID DEVELOPMENT GIVE • COLD RINSE SODA ASH NEUTRALIZATION HOT WATER RINSING SOAPING AT BOIL COLD RINSE DRY. SEMI-CONTINUOUS DYEING • PAD THE FABRIC WITH DYE SOLUTION • DEVELOP ON JIGGER LIKE IN EXHAUST DYEING • COLD RINSE, SOAP, COLD RINSE • IMPROVEMENT IN COLOUR YIELD IS OBTAINED BY • DRYING THE PADDED FABRIC BEFORE DEVELOPMENT