The Sequence

advertisement

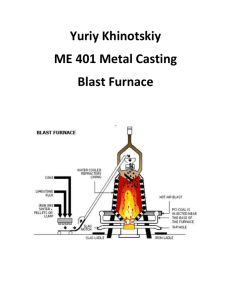

The production of Iron and Steel The Blast Furnace The Basic Oxegen Furnace The Electric Arc Frunace The Blast Furnace Downcomer Receiving hopper Charging Conveyor Tuyere –For Hot air Blasts Supporting Column Slag Hole Slag Trolley Blast Furnace Gas to Cleaning plant Distributing Chute Water Cooled Refractory lining Hot air Blast Tap hole Iron Trolley The Production of Iron 1. First the ore is graded and crushed and the fine particles sintered. Sintering is the process of converting fine particles into a continuous mass 2. Iron ore powder is compacted and then heated to a temperature below the melting point of the metal in the ore, this results in the waste being removed and the particles of iron ore gathering into ball shaped masses or agglomerates. 3. Conveyor buckets take iron ore, limestone and coke to the top of furnace 4. Once inside the furnace the whole mixture is ‘fired’, this brings it to a white hot temperature. 5. Smelted iron runs to the bottom of the furnace and is tapped off 6. The limestone combines with impurities and forms a slag and as this is lighter than the iron it floats to the top and is tapped off A blast furnace can run for 2 years before the refractory lining has to be replaced. Most of the molten iron goes directly to steel mills although some is cast into Buckets (Pigs). This is known as pig iron and is used to make Cast Iron Video Clip Blast Furnace Steelmaking Blast Furnace.flv The Basic Oxygen Process Fluxes and coolants Moveable seal Tap Hole Steel shell Fumes to cleaning plant Water-cooled fume hood Water-cooled lance Refractory lining (Dolomite) The Sequence 1. Charging • Scrap Iron and Steel form 30% of the charge • Molten Iron from the blast furnace makes up the rest Blowing • A water cooled pipe carries oxygen to the surface of the hot metal • Oxygen blows at high pressure which increases temperature and burns off impurities Sampling • Samples are taken to check the composition of the steel Tapping • Once chemical analysis indicates correct composition, lance is lifted out • Molten steel is poured through TapHole Removing Slag • Once chemical analysis indicates correct composition, lance is lifted out • Molten steel is poured through TapHole Video Clip Basic Oxygen Process Video Basic Oxygen Steelmaking (BOS).rm The Electric Arc Furnace Power Cables Swivel Roof Water cooled panels Carbon electrodes Refractory lining Tapping Spout Furnace Door Steel Scrap The Electric Arc furnace is a circular vessel that sits on a set of rollers which allow it to be tipped for Tapping and Slagging The Sequence 1. Charging • The charge consists solely of Scrap Iron 2. Melting • The electrodes are lowered, and the arc is started, by raising the electrodes a little above the surface of the scrap 3. Slagging • The furnace is first tilted on rollers to allow Slag to be raked off or poured into slag ladles. 4. Tapping • The furnace is then titled in the other direction and then the molten steel is poured out through a spout into the pouring ladle. Video Clip Electric Arc Furnace 1 Video Electric arc furnace 1.rm Video Clip Electric Arc Furnace 2 Video Electric arc furnace 2.rm