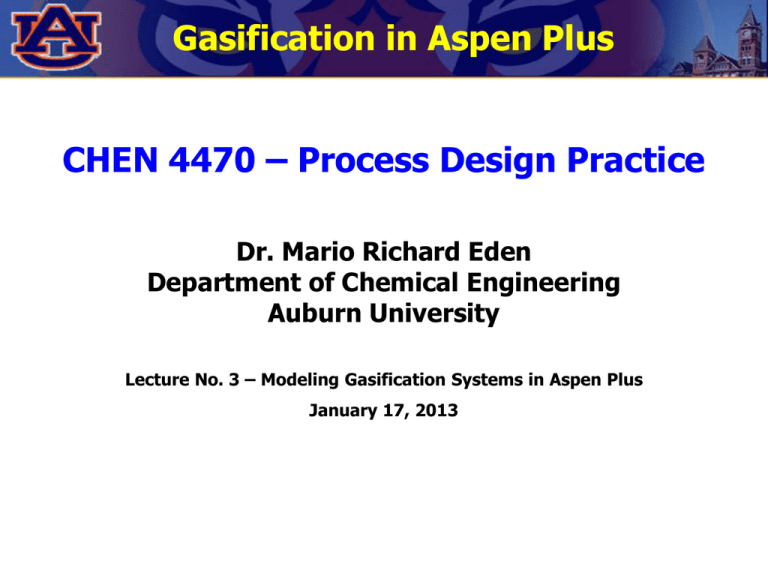

PPT - Auburn University

advertisement

Gasification in Aspen Plus CHEN 4470 – Process Design Practice Dr. Mario Richard Eden Department of Chemical Engineering Auburn University Lecture No. 3 – Modeling Gasification Systems in Aspen Plus January 17, 2013 Components Feedstock used in this example is Montana Sub-Bituminous Coal Note: NOT an exhaustive list. Stream Classes Used for models where you have both conventional (carbon) and nonconventional (coal/biomass + ash) solids present, but no particle size distribution Properties The first parameter (6) indicates that you want to enter the heat of combustion information yourself, rather than have Aspen estimate it. Properties Properties Enter a new pure component parameter here. Since we are entering the heat of combustion for the coal/biomass, it is classified as nonconventional Properties From feedstock information for Montana Sub-Bituminous Coal Feed Specification Simple basis: 1000 kg/hr Note that the coal is located in the NC substream! Feed Specification Note: PROXANAL values for FC, VM, and ASH sum to 100! Moisture is added separately. Feed Specification Note: ULTANAL values sum to 100! Values taken from feedstock description Feed Specification Note: SULFANAL values sum to ULTANAL value for sulfur! Sulfur breakdown from feedstock description: 45% pyritic, 45% organic, 10% sulfate Pyritic: 0.45*1.22 = 0.549 Organic: 0.45*1.22 = 0.549 Sulfate: 0.10*1.22 = 0.122 Coal Decomposition First reactor (RYIELD) serves to convert/decompose the coal/biomass into its constituent parts, i.e. H2, O2, N2, H2O, S, C, and ASH. This is NOT a true stand alone reactor, but an integral part of the gasification reactor. The decomposition reactor serves to convert the nonconventional solids into true components and ash. Coal Decomposition Coal Decomposition Yield distribution is entered as mass yield of component per total mass of feed and calculated from the ultimate analysis data: mH2 = (1 – XMoisture)*XH*mFeed = (1 – 0.105)*0.0489*1000 kg = 44 kg → yield H2 = 0.044 mO2 = (1 – XMoisture)*XO*mFeed = (0.895)*0.1304*1000 kg = 117 kg → yield O2 = 0.117 mN2 = (1 – XMoisture)*XN*mFeed = (0.895)*0.0149*1000 kg = 13 kg → yield N2 = 0.013 → yield H2O = 0.105 mH2O = XMoisture*mFeed = 0.105*1000 kg = 105 kg mS = (1 – XMoisture)*XS*mFeed = (0.895)*0.0122*1000 kg = 11 kg → yield S = 0.011 mC = (1 – XMoisture)*XC*mFeed = (0.895)*0.6684*1000 kg = 598 kg → yield C = 0.598 → yield ASH = 0.112 mASH = (1 – XMoisture)*XASH*mFeed = (0.895)*0.1251*1000 kg = 112 kg Coal Decomposition Note: It is necessary to specify that the ASH component is 100% ash in PROXANAL. Coal Decomposition Note: It is necessary to specify that the ASH component is 100% ash in ULTANAL. Coal Decomposition Note: It is necessary to specify that the ASH component is 0% sulfur in SULFANAL. Coal Gasification Second reactor (RGIBBS) serves to convert the decomposed coal/biomass into synthesis gas by reacting it with oxygen. The stream labeled GASFEED does not exist in reality. It serves as a means of transferring the constituent elements of the decomposed coal/biomass to the actual gasification reactor. It is necessary to link the two reactor blocks by a heat stream in order to take the energy required for the decomposition into account! Coal Gasification Simple basis: 1000 kg/hr You will need to identify the optimal oxygen feedrate along with temperature and pressure Coal Gasification Coal Gasification Important: The elementary carbon formed (if any) needs to be specified as a pure solid. Solids Removal The SSPlit subroutine allows for splitting the feed according to the individual substreams, i.e. It enables separating the solids that are ”carried” in the NC and CISOLID substreams to be separated from the gaseous products in the MIXED substream Solids Removal A Few Results Stream: SYNGAS Substream: MIXED Mole Flow kmol/hr HYDROGEN OXYGEN NITROGEN WATER SULFUR CO CO2 H2S METHANE C AMMONIA Total Flow kmol/hr Total Flow kg/hr Total Flow cum/hr Temperature C Pressure bar Vapor Frac Liquid Frac 15.6820753 4.47E-15 0.46290993 11.2474944 8.55E-09 34.8003674 14.797821 0.34304247 0.18950623 0 0.00230474 77.5255214 1888 273.345722 1005.92981 30.3975 1 0 Stream: ASH Substream: NC Mass Flow kg/hr COAL ASH Total Flow kg/hr Temperature C Pressure bar Vapor Frac Liquid Frac Solid Frac Enthalpy kcal/kg Enthalpy Gcal/hr Entropy Density kg/cum Average MW 0 112 112 1005.92981 30.3975 0 0 1 55.4111977 0.00620605 3486.88409 1