Catalytic wet air oxidation The Budapest University

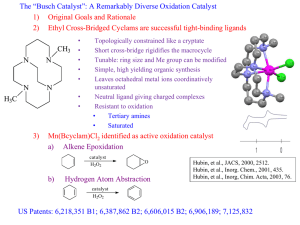

advertisement

Catalytic wet air oxidation The Budapest University of Technology and Economics Department of Chemical and Environmental Process Engineering Arezoo Mohammad Hosseini Supervisor: Prof. Tungler Antal 2007 Table of content Introduction Wet air oxidation (WAO) Catalytic wet air oxidation (CWAO) Experimental Conclusion Introduction Industries generate large quantities of aqueous wastes containing organic substances. Treatment of these waters has become a major social, technological, economical, and political problem. Waste water treatment: physical, chemical, and biological. Biological treatment: important for removal of organic pollutants, but often not suitable for waste streams originating from the chemical industry since they may contain toxic, non-biodegradable and hazardous pollutants. One of the present technologies used for non-biodegradable waste treatment is wet air oxidation (WAO) Heterogeneous catalysts used in wet air oxidation oxides of different transition metals such as Cu, Mn, Co, Cr, V, Ti, Bi, noble metals (Ru, Pt and Pd) Copper oxide: the most active among oxides. copper catalyst deactivate fast . This is because of formation of polymeric substances which are deposited on catalyst particles and leaching of active ingredients to the reaction medium. Carbon based materials are much more resistant to leaching in acidic solutions under WAO conditions than typical oxide supports but they are oxidized to carbon dioxide and consumed slowly. A 10000 WAO & Incineration Incineration Recovery Wet Air Oxidation (WAO) 100 H2O2 Fenton Fenton-likeD Biological AOP & Biological 1 Photochem. TOC, mg C/l WAO & Biological O3/H2O2 h Ozone 0.01 0 25 50 75 3 Flow Rate, m /h 100 Wet air oxidation Breaking down biologically refractory compounds to simpler, easily treatable materials. Effective method for The treatment of effluents containing a high organic matter content (COD 10–100 g l−1). Toxic contaminants for which conventional biological treatment processes are inefficient. It is a liquid phase process that takes place Elevated temperatures (200-300°C) Pressures (50-175bar) By means of active oxygen species, such as hydroxyl radicals . Under these conditions, complex organic compounds are mostly oxidized into: innocuous inorganic compounds such as CO2, H2O and hetero-atom dissolved ions, along with simpler forms such as short-chain carboxylic acids. Basic flow diagram of WAO plant . About 100 plants are at operation today. Waste streams from petrochemical, chemical and pharmaceutical industries as well as residual sludge from waste water streams. Catalytic wet air oxidation An alternative treatment technique to WAO. Use of suitable catalyst: Milder operation conditions and shorter residence time It might alter the selectivity of uncatalyzed oxidation towards the most readily biodegradable intermediates. Soluble metal salts (such as copper and iron salts) have been found to give significant enhancement of the reaction rate. They suffer from the draw back that their use necessitates a separation step. Mixtures of metal oxides of Cu, Zn, Co, Mn, and Bi leaching of these catalysts was detected. heterogeneous catalysts based on precious metals deposited on stable supports are less prone to active ingredient leaching. Experimental results of WAO of mildly concenrated chemical wastewaters indicated that over 50% reduction of the chemical oxygen demand could be achieved in about an hour at T>200°C and total operating pressure above 30bar. Table1. Summary of reported heterogeneous Catalytic WAO research Catalyst Active phase Application carrier Cu alumina Co Mn-Ce Mn-Zn-Cr Fe Ru-Rh Pt-Pd Ru none none none Silica alumina titania-zirconia titania-zirconia Phenol p-cresol alcohols, amines , etc. poly(ethyleneglycol) industrial wastes chlorophenols wet oxidizes sludge industrial wastes industrial wastes, sludge Experimental Methods of operation Instrument: 800 ml stainless steel high pressure autoclave Experiments were carried out: At 250˚C temperature and 50 bar pressure Liquid sample analysis with respect to their TOC and COD content TOC: Shimadzu TOC analyzer operation was based on catalytic combustion and non dispersive infrared (NDIR) gas analysis COD: The dichromate method Table2. Summary of some oxidation reactions Sample number Starting TOC (mg/ml) Starting COD (mg/ml) Catalyst Final TOC Final COD COD decrease (%) 4694 20090 68000 - 12850 35724 4695 25070 80000 - 17000 49980 37 5227 26580 80236 - 21608 32224 59 600 134700 525620 - 123200 430460 18 373 344000 1218000 Net 4823 9498 83 370 8450 24300 0,6g Pdo/TiO2 506 4467 83 Table3. metal content of some samples SAMPLE k Fe Ni 4694 0.5% 0.5% 4695 0.1% 5227 Cu Zn Sr Mo Cr 300ppm 400pp m - - - - 0.1% 100ppm 150pp m 50ppm 10ppm - - - 0.1% 10ppm 50ppm - - 5ppm - 600 - 0.03% - 2050ppm - - - - 370 - 300ppm 5ppm 200250 30ppm - 3ppm ppm Sample371(100) Sample number 371 and 370 They were relatively easily oxidizable (oxidized within 1-2 hours) With PdO/TiO2 higher reaction rate could be achieved. their final COD values went down almost to onetenth of the starting values. TOC (mg/ml) Conclusion 1000 900 800 700 600 500 400 300 200 100 0 0 50 100 150 Time,min Sample 373 (118) 19500 19000 Sample number 373 Highly concentrated acetic acid solution TOC (mg//ml) 18500 18000 17500 17000 16500 16000 Mesh (Titanium with a Ruthenium Mixed Metal Oxide coating) proved to be the most efficient . constant decrease in COD for example in case of the catalyst Net 15500 In general we can see a following trend in the effectivity of all catalysts used in this research work: 18000 16000 14000 12000 10000 8000 6000 4000 2000 0 Mesh > RuO2/TiO2 > PtO2/TiO2 > PdO/TiO2 0 50 100 150 200 250 300 Time min Sample 373 (119) TOC (mg/ml) 0 200 Time,min 400 600 Sample number 4694 The final COD value went down to half of the original value after almost 5 hours of oxidation. 23000 21000 19000 TOC (mg/ml) Sample 4694 Furhther oxidation was possible in longer period (COD reduction:66%) witout catalyst. 17000 15000 13000 11000 9000 7000 5000 0 100 500 30000 Constant COD decrease 68% COD reduction in almost 8 hours 400 Sample 4695 25000 TOC (mg/ml) 300 Time (min) Sample number 4695 200 20000 15000 10000 5000 0 100 200 300 400 500 600 Time (min) In general -Some Metal content (e.g. Fe) of these waste waters act as catalyst and accelerates the oxidation process -waste waters with high COD values(>100000 (mg/ml) )were not easily oxidizable Thank you for your attention