Advances Available for Research with our New Systems

advertisement

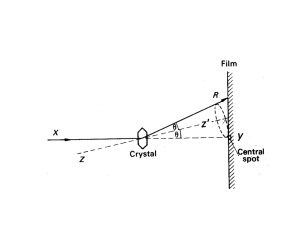

Earth & Planetary Science Applications of X-Ray Diffraction: Advances Available for Research with our New Systems James R. Connolly Dept. of Earth & Planetary Sciences University of New Mexico 401/501 Colloquium November 11, 2011 Outline • • • • • • What can you do with X-ray Diffraction? X-Ray Powder Diffraction – Introduction to the method Advances in X-ray detectors Our Current Scintag system – strengths and weakness Our New systems (arriving January) – new capabilities Details of our New Systems (as time allows at end) Acknowledgements: Thanks to Aya Takase, Al Larsen, and Sean Bird from Rigaku, USA, for help with technical graphics, Maarten DeMoor for use of his sample data, the National Science Foundation for funding our new instruments, and CoPIs Adrian Brearley, Abhaya Datye and Darren Dunphy for making it all happen. What can you do with X-ray Diffraction? • Identify crystalline materials in powdered samples • Determine of amounts of major and minor phases in multi-phase samples + • Obtain precise crystal structure data for phases in powders + • Analyze most materials totally non-destructively • Identify crystalline materials in thin coatings on natural or engineered materials * • Obtain good quality crystallographic data on extremely small amounts of material * • Analyze materials in controlled environments (oxygen-free, controlled gas, controlled temperature) * • Perform real-time experiments with materials under controlled conditions * • Identify phases in a non-destructive manner in intact small samples * * Indicates capabilities to be added with our new systems + Indicates capability greatly enhanced with our new systems What can’t you do with X-ray Diffraction? • Identify trace amounts of phases in a multi-phase sample – though new instruments can detect smaller amounts of material, trace amounts are difficult to impossible to detect • Quantitatively determine amounts of amorphous material in a sample – this can be done by “difference” with an internal standard but does not leave original material unaltered • Do single-crystal diffraction analysis (though this capability can be added to one of our new systems as an option) • Do direct chemical analysis of samples – XRD can do crystallographic analysis NOT chemical analysis Diffraction patterns contains two “components”: • Peak position provides information about crystal structure or “d-spacings” in a crystalline phase • Peak intensity provides information about the scattering power of those “d-spacings”; this is in turn related to the arrangements of constituent atoms in the structure and abundance of phases in a mixture • Lots of other information may be obtained from peak shape and symmetry The Bragg Equation n 2d sin where n is an integer is the wavelength of the x-rays d is the interplanar spacing in the specimen is the diffraction angle •The Bragg equation is the fundamental diffraction equation • It is used to calculate interplanar spacings in crystal structures • It is valid only for monochromatic X-rays. Intensity Scale An XRD Data Plot: 2 (x-axis) vs. intensity (y-axis) 2 Angular Scale Adding Peak Intensity Information to Positions • Different diffraction peaks show differing intensities • Scattering occurs at the atomic level • Intensities are related to how all of the scattered X-rays from atoms in a particular diffracting “dspacing” add as a vector sum • The combination of position and intensity is used to “fingerprint” particular crystalline structures (and often but not always unique phases) Detector Source Monochromator Specimen An XRD Data Plot: 2 (x-axis) vs. intensity (y-axis) Search/Match: Results Display Search/Match: Printout of Results X-ray Diffraction Patterns Gas Liquid / amorphous Powder / polycrystalline Single crystal Extracting Information from a diffraction pattern Whole pattern Phase identification, quantitative analysis Peak position Lattice parameters Peak width Crystallite size & strain Diffraction Amorphous scattering %Crystallinity Background Phase identification Differing Intensity from strong preferred orientation “Hump” in background indicates presence of amorphous material Our Existing Scintag Pad V System • Sturdy, solid, reliable, good quality data • Point detector collects data in 0.01° to 0.05° steps – avg. data collection times 1-2 hours per sample; overnight for high resolution (quantitative-capable) data • One sample at a time (no sample changer) • Cannot change parts easily – limited to Cu X-ray source, single sample stage, point detector, -2 “BraggBrentano” scans • Alignment is a several-day affair • Analytical Software (DataScan4 & Jade+) good but not well integrated with instrument • State-of-the-art system in 1985; upgraded but limited by its age Laboratory Needs • EPS XRD Lab is a service center used by multiple departments on campus including: E&PS, Various Engineering Departments and Institutes including CE, ChNE, CMEM, CHTM, Chemistry, Anthropology, Pharmacy, Biology, Water Resources Program • New System requirements: – – – – Easily reconfigurable for different analytical needs Operable by non-experts in XRD Easy, automated alignment after exchange of components Add new research capabilities including: • • • • • • • High throughput for standard powder analyses Microdiffraction (phase identification from very small areas) Non-ambient (atmosphere, controlled temperature & pressure) experiments High-speed data collection (for real-time experiments) Data collection from wet or damp materials Low-angle data from films and coatings Small angle scattering (SAXS) analysis for nano-materials New Systems to Arrive January 2012 • Funded by NSF MRI Grant to CMEM (ChNE) and E&PS • To best meet diverse needs of investigators, we opted for two new instruments: – Rigaku SmartLab Multi-purpose diffractometer capable of: • • • • • • Automated, multi-sample analysis w. sample spinning option 0D (Point) or 1D High Speed detector Non-ambient (elevated T, controlled environment) experiments Focused (parallel) X-ray beam or divergent beam geometry Horizontal sample orientation (low-volume and wet samples ok) Glancing Incidence, SAXS, GISAXS, HiRes XRD capabilities and more – Rigaku Rapid II • • • • Small area-micro-diffraction w. large 2D detector Work with very small amounts of powder or intact samples Obtain diffraction data with highly oriented crystalline material Standard powder diffraction (when other systems busy) Rigaku SmartLab Rigaku D-Max Rapid II 3-Dimensional Diffraction Space Powder Sample Advances in X-Ray Detectors • Point or “0d” detectors have a limited “view” of diffraction space – one point at a time, usually 0.2 to 0.5° • Data collection is by fixed time at each point, usually ½ to several seconds, thus slow • If lines are “spotty” because of preferred orientation, diffractions will be missed • Most common 0d detector is the Scintillation counter -- still widely used for many applications • Most efficient if used with a sample changer in unattended mode Advances in X-Ray Detectors • Linear or 1d Detectors sample a larger angular slice of diffraction space, usually 1-3° (but to 120° with specialized detectors) • Moves through a range of diffraction space as a “sliding window” collecting data throughout its angular range • Results in greatly increased speed of data collection (typically 50x to 100x that of a scintillation counter) • Most modern 1d detectors are some form of Silicon strip technology and are very durable and robust devices Rigaku D/teX Ultra 1d Detector Linear range of diffraction space (up to 1.5°) measured simultaneously = 50-100x faster data collection D/teX Ultra Zeolite sample measured in 60 seconds Variable temperature XRD experiment with D/teX Ultra Detector Advances in X-Ray Detectors • Area or 2d detectors view a substantial “slice” of diffraction space in two dimensions • Smaller 2d detectors can be moved through diffraction space and images combined to produce large map of 2d space • Larger 2d detectors can remain fixed recording a “snapshot” of 2d space • 2d detectors enable collection of diffraction data from samples with extreme preferred orientation – in some cases collecting useful data from single crystals Rigaku Rapid II Microdiffraction Advantages • Extremely large detector (25.6 x 46.6 cm) • Image plate records all X-ray energies – different sources (Cu, Co, and Mo) may be used. • Sources are easily changed • 3-axis sample stage allows many different sample types to be mounted and analyzed • Beam collimators cover range from 800 µm to 30 µm • Image recording times can be from 5 to 60 minutes (or more if needed) • Image is digitally read, data recorded and plate ready for reuse within a couple of minutes Meteorite ALH 84033 – Microdiffraction Data from Rigaku Rapid II “Black” area Meteorite ALH 84033 – Microdiffraction Data from Rigaku Rapid II “Brown” area Meteorite ALH 84033 – Microdiffraction Data from Rigaku Rapid II “White” area Using the XRD Lab • XRD lab is open to any faculty, students or staff wanting to incorporate XRD in their research • Radiation safety training and exam must be completed by all users • Training for equipment operation will be available • The lab is a service center so fees are charged for use • Fee schedules for analyses will be similar to that for the current instrument with additional schedules for use of new experimental equipment • Anyone wanting to incorporate XRD into research proposals should connect with me about how best to do that