Reversed Phase HPLC 2 - Chemical Engineering

advertisement

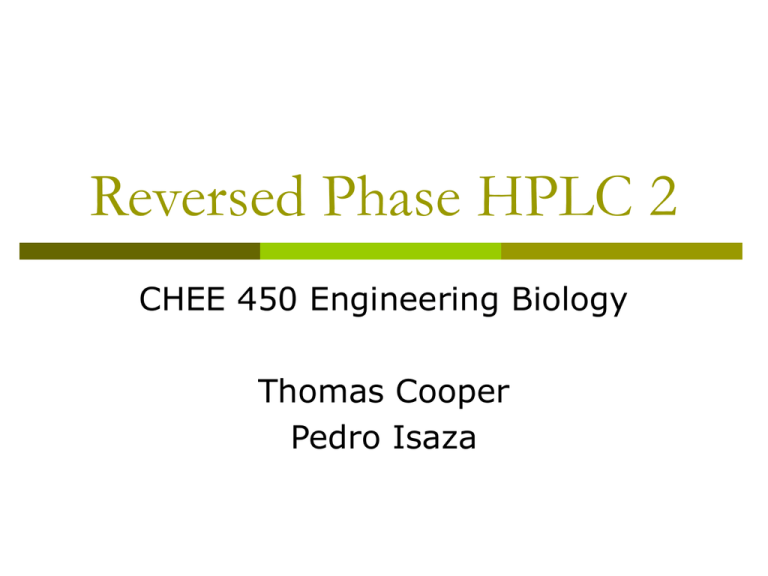

Reversed Phase HPLC 2 CHEE 450 Engineering Biology Thomas Cooper Pedro Isaza Purpose & Alternatives Final insulin product must be purified Mixture contains many impurities Unreacted insulin esters Precursors Deamidated insulin RP-HPLC demonstrated to separate insulin and insulin-like compounds differing by one amino acid Also possible with ion exchange chromatography Loss of product Lower yields How it Works HPLC able to separate based on charge, size, and hydrophobic character Hydrophobic analytes interact strongly with resin Hydrophilic pass freely through the column Organic solvents are used to elute hydrophobic molecules Design Requirements Annual insulin production of 4000 kg at 99% purity Insulin enters RPHPLC 2 at 530 g/h Minimum yield of 88% required Assume 100% binding 4600 4500 Insulin Production (kg/yr) 4400 4300 4200 4100 4000 3900 3800 85 90 95 RP-HPLC 2 Percent Recovery (%) Fig. 1: Overall annual insulin production as a function of the RPHPLC 2 unit recovery 100 Design Considerations General Operating Parameters Temperature range of 15 to 20 oC Pressure range of 20 to 100 bar Column Type Fixed-bed vs. Axial Compression Large size creates difficulties for efficient and reproducible packing Axial compression eliminates this problem Fig. 2: Illustration of “self-packing” axial compression column (TechniKrom, 2007). Design Considerations Packing (Stationary Phase) Lipophilically modified silica gels commonly used Fig. 3: Structure of C18 resin Alternative option is Amberchrom HPR10 For insulin purification, C8 to C18 yield best results Ideal particle size ≤ 12 µm and pore sizes of 120 to 150 Å Recommended for polishing stages of insulin purification Both display similar performance and cost More data available for silica-based materials C8 packing selected Design Considerations Column Size C8 suggested loading is 17 mg insulin/mL For 530 g/batch, 32 L of packing is required Mobile-phase pH Acidic conditions elute insulin before impurities Early elution improves yields Ideal pH range of 3 to 4 Well below isoelectric point of insulin (pH 5.4) Compatible with chosen silica resin (pH 2 to 8) high pH: dissolution of the silica very low pH: hydrolysis of attached C8 chains May lead to insulin deamidation Not significant problem due to short exposure times Design Considerations Organic Modifier for Elution Requirements: good insulin selectivity and low viscosity Acetone or acetonitrile are recommended Acetonitrile Well-documented analytical insulin separation High yields obtained at production scale Acetone Lower yields due to poor insulin solubility Loading, Elution, and Regeneration Scheme Load insulin onto column in aqueous-alcoholic, or purely aqueous, buffer solution Linear gradient ranging from 15 to 30% acetonitrile effectively separates insulin in 1 CV or less Regeneration with 60% acetonitrile and pH 7.4 Design Considerations Final Yields Minimum 88% yield required Yields from 83 to 98% documented for C8 Confirmation Product stream monitored via spectroscopy At 280 nm for insulin Insulin Peak Fig. 4: Elution of insulin and insulin derivatives under acidic conditions (Kroeff et al., 1989) Final Design – Batch Time To find number of columns required for continuous operation At inlet flowrate: loading time is 1 h Elution in 1 CV at 1.5 CV/h: elution time is 40 min Similarly, column regeneration time is 40 min Total HPLC cycle is 140 min 3 columns are required 4 recommended for unexpected failures Eluting Loading Regenerating Final Design – Cost Analysis Axial compression column 32 L required TechniKrom 35 L (30 cm ID x 50 cm): $80,000 Packing Kromasil C8 (10 µm, 100 Å): $150,000/column Average lifetime: 300 cycles 18 kg per column Quoted price of $8.02/g 7 re-packings required annually Chemicals High purity water (WFI): $50,000/year 120 kg WFI/h $0.05/kg Note: Neglected acetonitrile, acetone, and acetic acid Final Design – Cost Summary Table 1: Summary of costs associated with RP-HPLC 2 Item Qty Capital Cost ($) TechniKrom 35 L column 4 320,000 Kromasil C8 packing 4x7 4,200,000 High purity water Total cost Operating Costs ($/yr) 50,000 320,000 4,250,000 Questions?