Daramic separators - Chloride Technical & Trading

advertisement

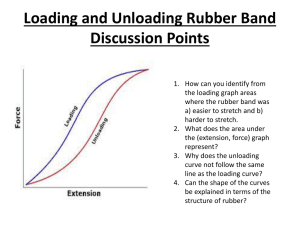

Separator design, formula and construction to maintain electrical performance of the lead acid battery Percentage of Cars per Driving Age Population USA Saudia Arabia Great Britian Germany South Korea Thailand India China 0 10 20 30 40 50 60 Penetration (%) Source: Nielsen Media Index & TGI Survey 70 80 90 100 Major Cities Population Tokyo Mumbai Shanghai Calcutta New York Los Angeles Chicago Philadelphia Paris European Cities Asian Cities USA Cities London Essen Milano 0 5 10 15 20 25 Population (millions) Sources: US Census Bureau and Times Atlas of the World, tenth edition 30 Average Temperature by Major City Calcutta Mumbai Shanghai Tokyo Los Angeles Philadelphia New York Asian Cities European Cities USA Cities Chicago Milano London Paris Essen 0.0 5.0 10.0 15.0 20.0 Mean Yearly Temp (degrees C) Source: www.weatherbase.com 25.0 30.0 Rubber Separators PE Separators Water Loss Test 21 Days Overcharge 2.4 V/Cell at 40 °C Positive PbSb 1.6 % / Negative PbCa – 2 Shot Formation Water Loss [g/Ah] 2 1.5 + 40% Improvement 0.8 1 0 Water Loss 21 Days Overcharge 2.4 V/Cell at 40 °C Positive PbCa / Negative PbCa – 2 Shot Formation Water Loss [g/Ah] 0.8 1 0.6 0 25% Improvement Increased Heat and Gassing Higher Recharge Currents Antimony Released from Positive Grid Results in Loss of Capacity and Battery Failure Negative Electrode Depolarizes Antimony Poisons Negative Electrode 80% DOD Cycling Test at 55°C 12.0 End of Charge Current (A) 10.0 8.0 6.0 Rubber 4.0 2.0 0.0 0 50 100 150 200 Cycles 250 300 350 80% DOD Cycling Test at 55°C 12.0 PVC End of Charge Current (A) 10.0 8.0 6.0 Rubber 4.0 2.0 0.0 0 50 100 150 200 Cycles 250 300 350 80% DOD Cycling Test at 55°C 12.0 PVC End of Charge Current (A) 10.0 Standard PE 8.0 6.0 Rubber 4.0 2.0 0.0 0 50 100 150 200 Cycles 250 300 350 80% DOD Cycling Test at 55°C 12.0 PVC End of Charge Current (A) 10.0 Standard PE 8.0 6.0 Rubber 4.0 Daramic HD 2.0 0.0 0 50 100 150 200 Cycles 250 300 350 Oxidation Resistance Increase Separator Back-web Thickness Increase Mass, Electrical Resistance and Acid Displacement Laminate Glassmat to Separator Prevents Shedding, Adds Component Formulation Changes Polymer and Anti-Oxidant Oxidation Resistance Test – Perox 80 1) Measure Separator Mechanical Properties a) Elongation, Puncture Resistance 2) Soak Separator in Oxidizing Solution a) b) Hydrogen Peroxide / Sulfuric Acid Elevated Temperature 80 degree C 3) Measure Remaining Separator Properties a) After Soaking various times (e.g. 20, 40, … hours) 4) Determine Rate of Oxidation with Drop in Mechanical Properties PEROX 80: Oxidation Resistance 450 400 CMD Elongation (%) 350 300 250 Daramic HP 200 150 100 End of Life < 100% 50 0 0 10 20 30 Soak Time (hrs) 40 50 60 PEROX 80: Oxidation Resistance 450 400 350 CMD Elongation (%) Daramic HP + 300 250 Daramic HP 200 25% Longer 150 100 End of Life < 100% 50 0 0 10 20 30 Soak Time (hrs) 40 50 60 Weight Loss in Perox 80 Solution 6.00 Weight Loss (wt%) 5.00 4.00 3.00 2.00 Standard PE Separator 1.00 0.00 0 50 100 150 200 250 Soak Time (minutes) 300 350 400 Weight Loss in Perox 80 Solution 6.00 Additive Level Weight Loss (wt%) 5.00 PE Separator with additive 4.00 3.00 2.00 Standard PE Separator 1.00 0.00 0 50 100 150 200 250 Soak Time (minutes) 300 350 400 Asian Market Summary SLI, Stationary and Motive Power Batteries High Population Densities Elevated Ambient Temperature Use of Antimony Alloy Elevated Temp & Antimony Alloy SLI Application Water Loss => Battery Dry-Out Rubber Additive to PE Separator Daramic HP+ Motive Power and Deep Cycle Application Negative Electrode Poisoning Loss of Capacity Rubber Additive to PE Separator Daramic HD Oxidation Resistance Rubber increases protection ~ 25% SLI Application Characteristic Units Daramic HP Daramic HP+ (1) Profile UI UI Rubber Additive No Yes Back-web Thickness microns 200 200 Puncture Resistance N 13.3 13.0 Electrical Resistance mohms-cm2 48.1 50.0 % 59.9 58.5 Acid Wet-out seconds 9.4 15.6 Residual Oil wt % Back-web 10.4 10.4 Total 16.2 16.5 368 414 CMD Elongation 20 hours 274 360 CMD Elongation 40 hours 112 214 0.44 0.31 Porosity CMD Elongation % Oxidation Resistance PEROX Acid Shrinkage % (1) US Patent 5,221,587 W. Boehnstedt et.al Deep Cycle Application Daramic CL Daramic HD (1) Profile BC BC Rubber Additive No Yes Characteristic Units Back-web Thickness microns 500 500 Electrical Resistance mohms-cm2 265 210 % 57.4 54.3 Ash Content wt % 69.3 72.8 Residual Oil wt % Back-web 14.8 15.1 Total 20.4 20.5 256 339 132 226 1.3 1.2 Porosity CMD Elongation % Oxidation Resistance PEROX CMD Elongation 20 hours Acid Shrinkage % (1) US Patent 5,221,587 W. Boehnstedt et.al Taipei 101 End