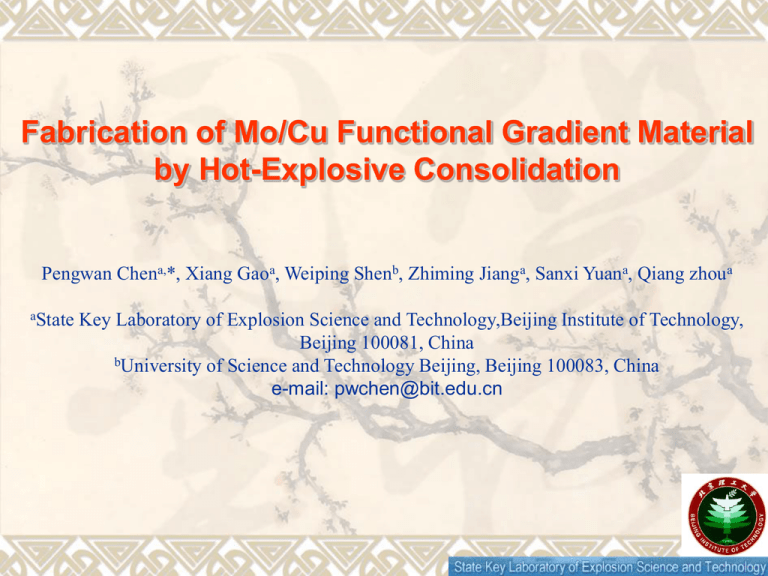

Fabrication of Mo/Cu Functional Gradient Material by Hot

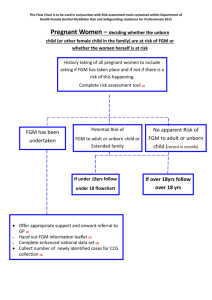

advertisement

Fabrication of Mo/Cu Functional Gradient Material by Hot-Explosive Consolidation Pengwan Chena,*, Xiang Gaoa, Weiping Shenb, Zhiming Jianga, Sanxi Yuana, Qiang zhoua aState Key Laboratory of Explosion Science and Technology,Beijing Institute of Technology, Beijing 100081, China bUniversity of Science and Technology Beijing, Beijing 100083, China e-mail: pwchen@bit.edu.cn Outline Introduction Hot-explosive consolidation apparatus Preheating by self-propagating high-temperature synthesis (SHS) Experiment and characterization Conclusions Introduction Functional gradient material (FGM) is a new kind of nonhomogeneous composite Mo(W)/Cu FGM combines the advantages of molybdenum and copper Powder metallurgy and hot isostatic pressing etc are traditional fabrication techniques of Mo(W)/Cu functional gradient materials Explosive consolidation provides a solution to fabricate high quality Mo/Cu FGM Hot-explosive consolidation apparatus 1. Detonator; 2. Explosive lens; 3. Water; 4. Protection tube; 5. Tungsten wire; 6. Mo/Cu FGM sample; 7. Copper sample box;8. Steel plate;9. SHS powders;10. Sand Experiment and characterization Design and fabrication of pre-compacted Mo/Cu FGM sample The average particle sizes of Mo powder and Cu powder were 3 µm and 74 µm, respectively The first layer contained only Mo with a thickness of 3 mm The seventh layer contained only Cu with a thickness of 2 mm. The other five gradient layers contained different ratios of Mo and Cu with a thickness of 1 mm for each layer. Composition of Mo/Cu FGM Preheating by self-propagating hightemperature synthesis (SHS) Self-propagating high-temperature synthesis(SHS) reaction was required to proceed in a confined small space during explosive consolidation A combined SHS system of (TiO2+Al+C) and (Fe2O3+ Al) were used to preheat the pre-compacted Mo/Cu FGM sample The mass ratio of (TiO2+Al+C) to (Fe2O3+Al) is 60%: 40%~80%: 20%. The pre-compacted Mo/Cu FGM sample can be preheated rapidly to 300℃~1000℃ in a small space by regulating the mass ratio of (TiO2+Al+C) to (Fe2O3+Al). Typical temperature rise curves in FGM powder and water Experiment and characterization Shock wave propagation and shock pressure measurement The propagation and interaction of shock waves during explosive consolidation were studied with flash X-ray cineradiography The shock pressures during the passage of shock waves were measured by manganin pressure gauges. MODEL1200-type flash X-ray camera system of Swedish Scandiflash AB Company Two space-time associated flash X-ray high-speed cameras The angle between two camera axis was 30°~45° B 爆炸洞壁 爆炸中心 底片A X射线脉冲发生器 底片B A 防护窗口 The shock pressure histories at different locations during explosive consolidation were recorded by the embedded manganin pressure gauges Results of shock wave peak pressures Densities and thickness of gradient layers of Mo/Cu FGM Microstructure of Mo/Cu FGM: (a) FGM-7 (Cu)/FGM-6; (b) FGM-6/FGM-5; (c) FGM-5/FGM-4; (d) FGM-4/FGM-3; (e) FGM-3/FGM-2; (f) FGM-2/FGM-1 (Mo) 220 6.0 200 5.5 /105Scm-1 HV/× 10MPa 180 160 140 5.0 4.5 4.0 3.5 120 3.0 100 2.5 2.0 80 1.5 0 10 20 30 40 50 60 70 80 90 100 Cu content, V% Hardness as a function of Cu content of gradient layers 0 10 20 30 40 50 60 70 80 90 100 Cu/V% Electrical conductivity curve of Mo/Cu FGM Thermal conductivity of FGM-3 & FGM-4 layer c p Shear fracture surface morphology of FGM-1/FGM-2: (a) SEI of fracture surface; (b) backscattered image of fracture surface; (c) composition analysis image of Mo in (b); (d) composition analysis image of Cu in (b) Conclusions The symmetry and planeness of the bidirectional shock waves generated by the explosive consolidation assembly are fairly good. The pre-compacted Mo/Cu FGM sample can be preheated rapidly to 300℃~1000℃ in a confined small space by the exothermic reaction of self-propagating high temperature synthesis. The average relative density in the consolidated FGM can reach 95% For refractory molybdenum, plastic flow and volume diffusion mechanism may be dominant for the lack of liquid phase during sintering. For copper rich layer, viscous flow may be the major sintering mechanism as its relatively low melting point and good plasticity. Thank you very much!