Che5700 陶瓷粉末處理

advertisement

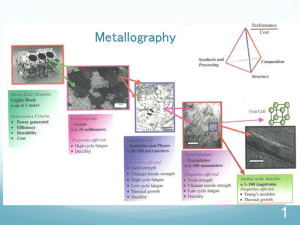

Che5700 陶瓷粉末處理 Solid State Reactions Several possible cases: solid/solid reaction; gas/solid reactions; solid decomposition reaction; etc. characteristics: Difficult to reach uniformity (compared to liquid, gas phases) Slow reaction rate, require high temperature and long time Reaction starts from surface, often left unreacted cores May form un-wanted intermediate phases (solid/solid system) Need grinding after reaction to get fine particles May introduce impurity during grinding Not many steps, the cost may be reasonable Che5700 陶瓷粉末處理 SiC powder synthesis • Competitive between different methods (1) Acheson process: SiO2 sand + C (coke) electric arc furnace (> 2000oC) coarse SiC grinding, purification; major method, impurity include: unreacted Si, Fe, O etc; side reaction SiO2 + C SiO + CO (reverse at low temperature, get fine dust) (2) Gas phase method: SiH4, SiCl4, chlorosilane as raw material + CH4 (or C2H4) heating, gas phase reaction (even by plasma, or laser) collect product, impurity from source, or due to incomplete reaction • High purity light green color (> 99.8%); next dark green (~99.5%), black (~99%), gray (~90%) • One of source - petroleum coke: not cheap •Comparison of come commercial SiC processes; some may have patent limitations; •Can use HF to dissolve unreacted SiO2 Che5700 陶瓷粉末處理 Si3N4 powder synthesis (1) Direct nitridation: Si powder grinding + catalyst and binder kneading form and dry high temperature nitridation grinding, sieving, purification remove un-reacted parts get final product (exothermic reaction, may lead to very high temperature to cause melting of Si) (2) Gas phase reaction: SiCl4 + NH3 to get first Si(NH)2 + NH4Cl calcine to remove NH4Cl, HCl precursor powder Si(NH)2 1000oC calcination to get amorphous Si2N3H (remove NH3) further heating 1400-1500oC to get crystalline Si3N4 (3) Liquid phase reaction: similar to previous process, use liquid NH3 filtration and washing to get silicon imide Si(NH)2 calcination to product Che5700 陶瓷粉末處理 Si3N4 powder synthesis (2) • SiCl4 (g) + NH3 (g) Si(NH)2 + NH4Cl (s) H = 161.5 Kcal/mol …. Exothermic reaction, need temperature control (4) SiO2 + C powder grinding and mixing under N2 (may have some hydrogen to minimize oxidation), heating and reacting grinding and sieving purification product Mostly heterogeneous reactions; some homogeneous reactions Taken from 陶 業雜誌 L Carbothermal reaction Gas phase SiCl4 + liquid phase NH3 reaction system •Comparison of some commercial Si3N4 processes and product characteristics •Product can be in the form of , , or amorphous form; beta form: most stable form, difficult to sinter, avoid to get it Comparison of costs; numbers will change with time and place Taken from Am. Cer. Bull. 70(1), 1991. So many different raw materials, product characteristics also different (including cost) Che5700 陶瓷粉末處理 AlN Powder Synthesis Gas phase: AlCl3 + 4 NH3 AlN + 3 NH4Cl; 900-1500oK, >5 hr …high cost, low yield Organo-metallic precursor: R3Al(l) + NH3 R3AlNH3 in sequence to get AlN + 3 RH; 400-1000oK (as above, may get residual carbon) Alumina + carbon reduction method: Al2O3 + N2 + 3C 2 AlN + 3 CO; 1500-2200oK, >5hr; with industrial process Direct nitridation of Al: 2 Al + N2 2 AlN; 1000-1500oK, >5hr, also with industrial process Combustion method: new, with potential Different processes are in competition with each other Che5700 陶瓷粉末處理 Important parameters of reaction As shown in SiC process, several important parameters: Purity of raw materials, size, surface condition,etc. Degree of mixing between raw materials (distance for diffusion) Any carrier (solvent, or carrier gas)? Its purity and effect Reaction temperature and time Catalyst or not? (some impurity may have catalytic effect) Reaction path (mechanism), any intermediates? Shrinking core & shrinking sphere models Examples of Shrinking Core Reactions FeO + H2 Fe + H2O CaCO3 + heat CaO + CO2 Che5700 陶瓷粉末處理 Thermodynamics and Kinetics To show whether the reaction is a spontaneous reaction; G negative, then spontaneous, unless limited by kinetics or mass transfer effect (most likely). Reactions can be divided into: decomposition, oxidation, reduction, etc.; may be multiple; Items to show effect on thermodynamics: gas phase: partial pressure, total pressure, moisture, or even CO2; Grxn Go RT ln K Che5700 陶瓷粉末處理 Solid state diffusion In theory, gas/solid reaction, rate control steps may include: (a) surface reaction; (b) mass transfer around particle; (c) diffusion inside product layer; (d) heat transfer around particle; (e) heat transfer inside product layer. Most often: mass transfer of the solid phase. • Control mechanism may change with temperature Taken from TA Ring, 1996, different temperature, different controlling mechanism Che5700 陶瓷粉末處理 Shrinking Sphere Model If product flakes off the original particle shrinking sphere model, e.g. CaCO3 decomposition reaction Steps included in this model: (a) mass transfer of A to particle; (b) surface reaction; (c) mass transfer of product away from particle; (d) heat transfer Another type of model: nucleation and growth model – e.g. 7 C + 2 B2O3(l) B4C (s) + 6 CO (g) ; where nucleation and growth of B4C – major mechanism; Avrami kinetics: ln( 1 – XB) = - (k t)m (general form); Che5700 陶瓷粉末處理 Solid-Solid Reactions A major type, many examples, e.g. NiO + Al2O3 NiAl2O4 ZnO + Al2O3 ZnAl2O4 BaCO3 + TiO2 BaTiO3 + CO2 (g) 4 B + C B4C SiO2 + C SiC + CO2 carbothermal reaction In addition to solid state diffusion, at sufficient high temperature, may change to gas phase reaction mechanism, e.g. SiO2 + C SiO (g) + CO; SiO + 2C SiC + CO (free energy change of former reaction less than zero at >1900oK) Partial pressure of oxygen competitive between formation of oxide or carbide CO + ½ O2 CO2 K = PCO2/[PCO x PO2] Solid-Solid Inter-diffusion Diffusion flux ~ (concentration) Ci, ion mobility Bi and electrochemical potential gradient, 所以影響 固相擴散的因素就是影響上述諸項目的因素 = chemical potential; = electrical potential; Z = valence of species; F = Faraday constant; d i J i Ci Bi dx [1 ( Z 1) X B ] 2/3 i i Zi F ( Z 1)(1 X B ) 2/3 2K Z (1 Z ) 2 t R Carter eq. For solid reaction kinetics •Taken from TA Ring, 1996; •Several different mechanisms •Charge balance should be maintained, if form space charge electrical field, affect ion mobility (in opposite direction); • diffusion couple; often controlled by the slower (moving) one Impurity (Fe) effect: form - whisker; T Schematic for mechanism: nucleation of Si3N4 on Si growth + CVD Si3N4 (whisker form) will stop further reaction between Si & N2 Vapor-Liquid-Solid (VLS) Growth Mechanism dissolution of gaseous reactants into nanosized liquid droplets of a catalyst metal product in alloy liquid product concentration keeps increasing crystallization of product to form a liquid-solid interface growth of solid region in confined direction nanorods nanowires JACS,2001,123,3165 呂世源教授提供 VLS Examples birth of a Ge nanowire on a Au nanocluster Ge nanowires with Au as catalyst Single crystal nanowire Au clusters remain as the tip of nanowires ( dark dots) JACS,2001,123,3165 呂世源教授提供