Chapter 5: Automation, Infiltration, and Embedding

advertisement

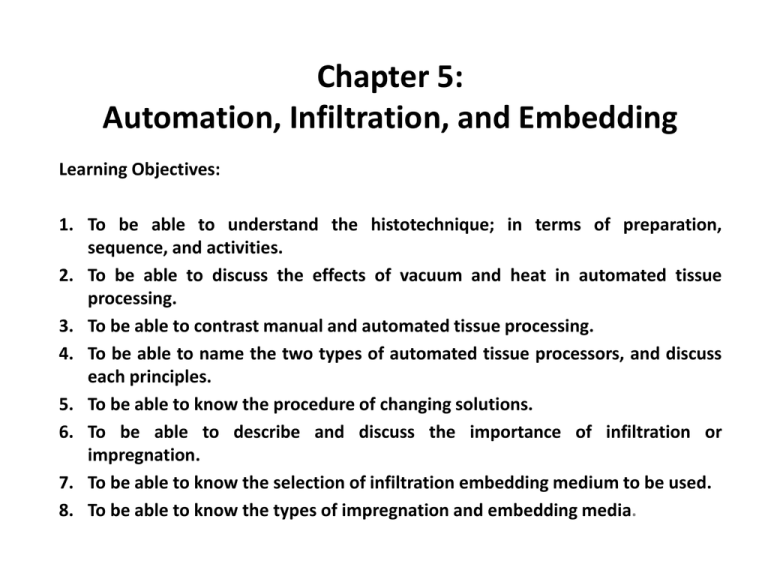

Chapter 5: Automation, Infiltration, and Embedding Learning Objectives: 1. To be able to understand the histotechnique; in terms of preparation, sequence, and activities. 2. To be able to discuss the effects of vacuum and heat in automated tissue processing. 3. To be able to contrast manual and automated tissue processing. 4. To be able to name the two types of automated tissue processors, and discuss each principles. 5. To be able to know the procedure of changing solutions. 6. To be able to describe and discuss the importance of infiltration or impregnation. 7. To be able to know the selection of infiltration embedding medium to be used. 8. To be able to know the types of impregnation and embedding media. Learning Objectives: 9. To be able to know the factors qualifying paraffin wax as the most common and best medium. 10. To be able to know the properties of paraffin wax. 11. To be able to know the melting point of paraffin wax 12. To be able to discuss the problems associated with infiltration process. 13. To be able to know the ideal properties of infiltration and embedding media. 14. To be able to describe, discuss the importance, and know the other names of embedding. 15. To be able to discuss and contrast the process of embedding frozen sections. 16. To be able to know the importance and procedure for tissue orientation. Automated Tissue Processor In modern laboratories - dehydration, clearing and infiltration are all carried out by automated tissue processor. It can also perform in accelerated mode (taking a shorter time period) by subjecting it to vacuum and heat (40 degrees Celcius). Smaller laboratories in developing countries however, still perform manually. In the hands of a good technician, the manual procedure is in no inferior to automated tissue processing but the former is tedious and requires constant attention. Interruptions in the electricity supply and lack of service support may cause problems in automated tissue processor. Two broad types of automation processors; a) tissue transfer b) fluid transfer. Tissue transfer automatic processor Tissue transfer – A series of stationary vats (containers), arranged in a circle with a timing device. These vats hold reagents and paraffin wax. The basket (receptacle) holds the cassettes and automatically changes position and takes a bath in different reagents kept in vats at a certain time, in order to accomplish dehydration, clearing and infiltration. Fluid transfer – fluids are pumped to and from a retort in which the tissues remain stationary. Fluid transfer automatic processor Changing of Solutions The fluids used in complete dehydration and clearing tend to become contaminated with fluid carried over from previous vat by the tissue. After using them for 2 – 3 days, the last solution in the series (e.g. xylene 2) is replaced by fresh solution, and the previously used one is moved forward while the first one (e.g. xylene 1) is discarded. Infiltration (Impregnation) Infiltration or impregnation is done after dehydration and clearing. Tissue must be infiltrated with the supporting (embedding) medium, in order to hold the cells and intercellular structures in their proper relationship while sections are being cut. The medium used to infiltrate the tissue is usually the same medium utilized for impregnation. There are generally four types of tissue impregnation and embedding media, namely; 1. Paraffin wax 2. Celloidin 3. Gelatin 4. Plastic (L to R) Paraffin pellets with paraffin block, paraffin pellets Paraffin wax remains the most common and the best medium because; 1. large numbers of tissue blocks may be process in a short time 2. serial sections are easily obtained, and 3. routine and most special staining can be done easily Paraffin wax properties: 1. Is used for routine embedding 2. Melting point at 56 – 58 degrees Celcius 3. It is a polycrystalline mixture of solid hydrocarbons produced during the refining of coal and mineral oils. 4. It is about two thirds the density and slightly more elastic than dried protein. Inadequate impregnation leads to drying and shrinking of embedded tissues. In addition, during cutting, cracks and crumbles develop if tissues are inadequately supported by wax. On the other hand, excessive exposure to high temperature (higher than 5 degrees melting point) will over harden the tissues and will not yield good sections. Ideally the infiltrating and embedding media should be: 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. Soluble in processing fluids Suitable for sectioning and ribboning Molten between 30 - 60 degrees Celcius Translucent or transparent; colorless Stable Homogenous Capable of flattening after ribboning Non-toxic Odorless Easy to handle Inexpensive Embedding (Casting or Blocking) It is a method of placing the infiltrated tissue in warm liquid paraffin (embedding medium) that solidifies into a firm block when it cools down to room temperature. This process provides support to the tissue to be cut on a microtome. During this process the tissues are placed into a mold along with embedding medium which is then hardened by cooling. Embedding Embedded Frozen Sections The frozen sections In frozen, un-fixed sections, the embedding medium is not needed. The water in the tissue is frozen, and as ice produces a firm block of tissue, the ice acts as the embedding medium. Tissue orientation in mold (L to R) Metal mold, metal mold with cassette, paraffin block During embedding, it is important to orient the tissue in a way that will provide the best information to the pathologist. Ideally done at the time the pathologist is taking out the “bit or block” from gross specimen. The pathologist may notch with a scalpel or mark with india ink the side opposite that is to be cut.