Calcium Sulfate

advertisement

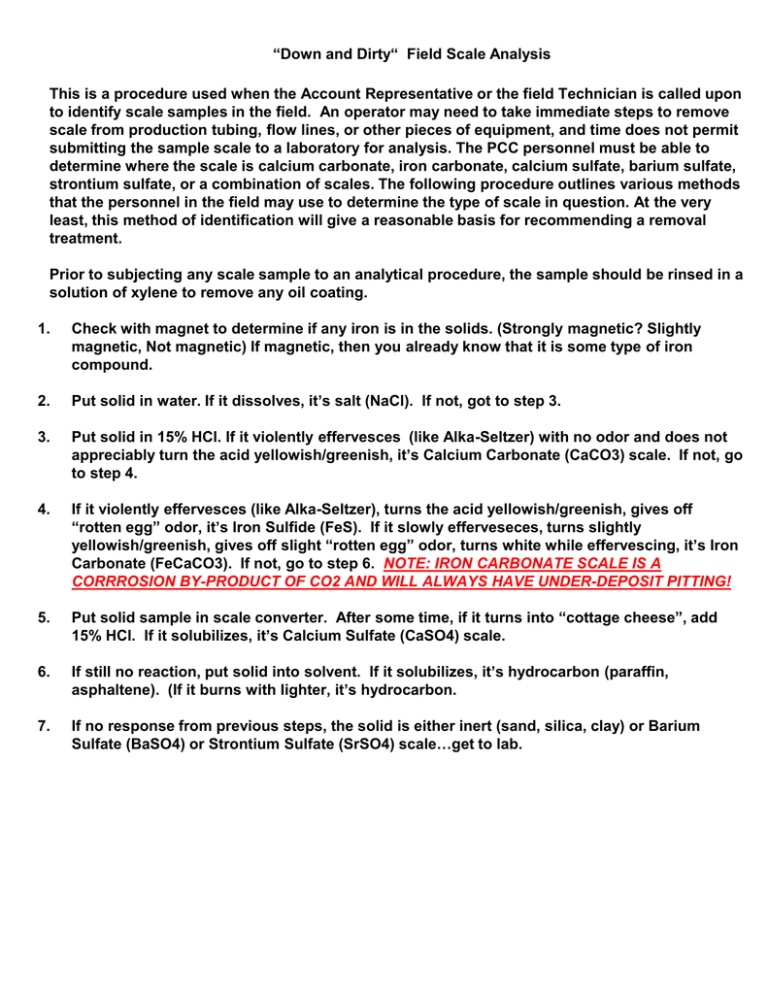

“Down and Dirty“ Field Scale Analysis This is a procedure used when the Account Representative or the field Technician is called upon to identify scale samples in the field. An operator may need to take immediate steps to remove scale from production tubing, flow lines, or other pieces of equipment, and time does not permit submitting the sample scale to a laboratory for analysis. The PCC personnel must be able to determine where the scale is calcium carbonate, iron carbonate, calcium sulfate, barium sulfate, strontium sulfate, or a combination of scales. The following procedure outlines various methods that the personnel in the field may use to determine the type of scale in question. At the very least, this method of identification will give a reasonable basis for recommending a removal treatment. Prior to subjecting any scale sample to an analytical procedure, the sample should be rinsed in a solution of xylene to remove any oil coating. 1. Check with magnet to determine if any iron is in the solids. (Strongly magnetic? Slightly magnetic, Not magnetic) If magnetic, then you already know that it is some type of iron compound. 2. Put solid in water. If it dissolves, it’s salt (NaCl). If not, got to step 3. 3. Put solid in 15% HCl. If it violently effervesces (like Alka-Seltzer) with no odor and does not appreciably turn the acid yellowish/greenish, it’s Calcium Carbonate (CaCO3) scale. If not, go to step 4. 4. If it violently effervesces (like Alka-Seltzer), turns the acid yellowish/greenish, gives off “rotten egg” odor, it’s Iron Sulfide (FeS). If it slowly efferveseces, turns slightly yellowish/greenish, gives off slight “rotten egg” odor, turns white while effervescing, it’s Iron Carbonate (FeCaCO3). If not, go to step 6. NOTE: IRON CARBONATE SCALE IS A CORRROSION BY-PRODUCT OF CO2 AND WILL ALWAYS HAVE UNDER-DEPOSIT PITTING! 5. Put solid sample in scale converter. After some time, if it turns into “cottage cheese”, add 15% HCl. If it solubilizes, it’s Calcium Sulfate (CaSO4) scale. 6. If still no reaction, put solid into solvent. If it solubilizes, it’s hydrocarbon (paraffin, asphaltene). (If it burns with lighter, it’s hydrocarbon. 7. If no response from previous steps, the solid is either inert (sand, silica, clay) or Barium Sulfate (BaSO4) or Strontium Sulfate (SrSO4) scale…get to lab. Soluble in water = salt (NaCl) Not soluble in water BUT, when exposed to acid = Violent reaction with HCl = CaCO3 No reaction with water or HCl Scale converter turns it into an acid soluble sludge HCl solubilizes acid soluble sludge, i.e. converted scale = CaSO4 Scale Sludge Coated Scale in 15% HCL + Micel Scale in Heavy Sludge Approximately 10 Seconds Later Micel solvents, such as PCC Acid Booster, prevents acid emulsions, removes hydrocarbons from acid soluble material, prevents sludge, increases permeability, leaves formation rock “water wet” QUALITATIVE ANALYSIS OF SOLIDS Soluble in HCL Component Soluble in Solvent Magnetic Reaction Acid Color Smell Water Soluble Hydrocarbons Yes No None None None No CaCO3 No No Violent None None No CaSO4 No No None None None No BaSO4, SrSO4 No No None None None No FeS No Weak Strong Yellow H2S No Fe2O3 No No Weak Yellow None No Fe3O4 No Strong Weak Yellow None No FeCO3 No No V Strong Yellow None No NaCl No No None None None Yes Sand, Silt, Clay No No None None None No QUALITATIVE ANALYSIS OF SOLIDS Soluble in HCL Component Soluble in Solvent Magnetic Reaction Hydrocarbons Yes No None CaCO3 No No Violent CaSO4 No No None No BaSO4, SrSO4 No No None No FeS No Weak Strong Yellow H2S No Fe2O3 No No Weak Yellow None No Fe3O4 No Strong Weak Yellow None No FeCO3 No No V Strong Yellow None No NaCl No No None Yes Sand, Silt, Clay No No None No Hydrocarbons Paraffin; Asphaltenes CaCO3 Calcium Carbonate; Calcite CaSO4 Calcium Sulfate; Anhydrite; Gypsum BaSO4, SrSO4 Barium Sulfate, Barite; Strontium Sulfate, Celestite FeS Iron Sulfide Fe2O3 Iron Oxide Fe3O4 Iron Hydroxide FeCO3 Iron Carbonate NaCl Salt Sand, Silt, Clay Inerts Acid Color Smell Water Soluble No None None No Scaling Tendency Calculations Calcium Carbonate: Multiply mg/liter of Bicarbonate by the mg/liter of Calcium If the resulting product is: Below 500,000 Above 500,000 Above 1,000,000 Tendency Remote Tendency Possible Tendency Probable Calcium Sulfate (Gypsum): Multiply mg/liter of Sulfate by the me/liter of Calcium Below 5,000,000 5,000,000 to 10,000,000 Above 10,000,000 Tendency Remote Tendency Possible Tendency Probable Cations *Calcium (Ca) *Magnesium (Mg) *Sodium (Na) *Iron (Fe) *Barium (Ba) Strontium (Sr) Manganese (Mn) Table 1 Primary Constituents of Oilfield Waters Anions Other Properties *Chloride (Cl) *pH *Carbonate (CO3) *Temperature *Bicarbonate (HCO3) *Specific Gravity *Sulfate (SO4) *Dissolved Carbon Dioxide *Sulfide as H2S Resistivity Dissolved Oxygen Bacterial Population Oil Content Turbidity Suspended Solids amount, size, shape, chemical composition – The components marked with an (*) are essential to obtaining a thorough and meaningful water analysis. Table 2 Relative Solubilities of Mineral Scales in Water Mineral Scale Solubility (mg/L) in Water Calcium Sulfate (Gypsum) - CaSO4 . 2H2O Calcium carbonate - CaCO3 2080 mg 53 mg Barium Sulfate - BaSO4 2.3 mg - - - Table 3 Primary Variables in the Formation of Mineral Scales Scale, or Deposit Chemical Formula Calcium Carbonate CaCO3 Calcium Sulfate CaSO4 . 2H20 (dehydrate) CaSO4 (anhydrite) Barium Sulfate Strontium Sulfate BaSO4 SrSO4 Iron Compounds: Iron Carbonate Iron Sulfide Iron (II) Hydroxide Iron (III) Hydroxide Iron Oxide FeCO3 FeS Fe(OH)2 Fe(OH)3 Fe2O3 Primary Variables -Partial pressure of CO2 (scale increases as CO2 decreases) -Less Soluble with Increasing temperature -Pressure Drops -More soluble as TDS increases -Less Soluble with Increasing temperature -Pressure drops -More soluble as TDS increases -More soluble as Temperatures increase -More soluble as TDS increases -Corrosion by-products -Bacterial activity -Dissolved gases -Depositions increase as pH increases (especially true after an acid job with spent acids) Type Detail Probable Origin Table 4 Common Suspended Solids and their Probable Origins Iron Hydrocarbons Carbonates Sulfates Compounds -Oil Carry Over -Iron sulfide -Calcium -Calcium Insolubles/organics -Formation fines -Paraffin Deposition -Iron oxide -Iron carbonate carbonate -Iron carbonate Magnesium carbonate sulfate -Magnesium sulfate -Barium sulfate -Sand -Microbes Asphaltenes -Separator malfunction -Truck treating schedules -Surface tank damages -Improper equipment sizing -Corrosion -Incompatible waters -Oxygen introduction -Stimulation byproducts -Scaling waters -Corrosion -Pressure drops -Fluid property changes -Scaling water -High temperature -Pump outlets/shrouds -Incompatible waters -Inadequate wellbore cleanouts -Pump intakes set low -Bacterial activity -Natural, or induced, formation of asphaltenes (CO2flood) Figure 1 - Representative Water Analysis Indicating Scaling Tendencies Figure 2 - Calcium Carbonate Scale Figure 3 - Calcium Sulfate Scale Figure 4 - Barium Sulfate Scale