Slide 1 - AAMU Myspace Login

advertisement

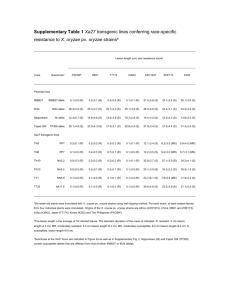

Nanjing Forestry University Experience 南京林业大学经验 Gilda Naka June 6, 2013-July 3, 2013 Gilda Naka Special Thanks to Dr. Wang Fei, Dr. Liaw Goang, Dr. Zhang Yu,He Qiyang 特别感谢王飞教授、廖广信教授、张瑜副教授、何琦阳同学 The process of producing biofuel through the transesterfication of triglycerides. ◦ This involves reacting vegetable or animal fats with short-chain alcohols (typically methanol or ethanol). Advantages: ◦ Domestically produced ◦ Biodegradable ◦ Renewable and Clean energy Industries use chemical methanolysis with alkalicatalysis ◦ Difficult removal of catalyst ◦ Excessive Energy Requirements Using lipase is better ◦ Glycerol is by-product (easily recovered) ◦ Simple purification of fatty methyl esters Two Types of Lipase Extracellular Expensive (recovery, purification, immobilization process) Intracellular Whole-cell biocatalyst ◦ No purification necessary ◦ R. oryzae whole cell with polyurethane foaming plastic Reaction involves two steps: 1) Hydrolyzation(水解反应) Rate Determining Step 2) Esterification (酯化反应) Reaction with ROL: ROL Reacts bean oil to glycerol and fatty acids Maximum methyl ester = 66.6% Reaction #1: Acyl migration (酰基迁移) Reaction #2: ◦ Water affects concentration of methyl ester Smaller concentration Slower reaction Excess H2O limits Reaction #2 Investigate the optimal amount of water needed to produce biodiesel via whole cellcatalyzed transesterfication of bean oil Prepare Fermentation Medium Breed Cultivation of R. oryzae Introduce R. oryzae to Medium Retrieving Whole-cell biocatalyst (foam) Biodiesel Production with Varying Water Content Chemical Mass Percent Tryptone 2% MgSO4 · 7H2O 0.05% NaNO3 0.1% KH2PO4 0.1% Bean oil 3% polyurethane foaming plastic 0.6 g (except control) pH = 5.5 4 beakers with 80 mL of medium Medium was autoclaved ◦ 20 minutes at 121° C Prepare Fermentation Medium Breed Cultivation of R. oryzae Introduce R. oryzae to Medium Retrieving Whole-cell biocatalyst (foam) Biodiesel Production with Varying Water Content Ingredients: ◦ D-(+)-Glucose ◦ Potato 2% 20% 50 mL of potato juice and 0.1 g D-(+)-Glucose Autoclaved for 1 hour then inoculate and place in incubator at 28°C 180 rpm until mold appears Agar (2%) was added to the petri dish as a storage medium Prepare Fermentation Medium Breed Cultivation of R. oryzae Introduce R. oryzae to Medium Retrieving Whole-cell biocatalyst (foam) Biodiesel Production with Varying Water Content Inoculate ROL (after 10 min UV sanitation of beakers) Cultivation 60 hours at 28° C at rotation speed of 180 rpm Prepare Fermentation Medium Breed Cultivation of R. oryzae Introduce R. oryzae to Medium Retrieving Whole-cell biocatalyst (foam) Biodiesel Production with Varying Water Content Wash polyurethane foaming plastic 3-5 times with water and squeeze Add 200mL of glutaraldehyde (1%) Glutaraldehyde contains the lipase in the foam Covered with gauze and incubated for 1 hour at 25°C, 180 rpm Add phosphate buffer (diluted 10 times) 6.5 mL of KH2PO4 50 mL of Na2HPO4*12H2O Put in ice water for 5 min Put in watch glass and dry in multi-thermo incubator for 10 hours at 30°C Polyurethane Foam with no R. oryzae Polyurethane Foam with R. oryzae Prepare Fermentation Medium Breed Cultivation of R. oryzae Introduce R. oryzae to Medium Retrieving Whole-cell biocatalyst (foam) Biodiesel Production with Varying Water Content 6 beakers Bean oil (15g) Methanol (680mL) 25 pieces of R. oryzae foaming plastic (not in control) Varying percents of water (0%-20%) In shaker for 12 hours at 37°C 150 μL into 6 test tubes every 12 hours 680 μL methanol added and shake for 12 hours Methanol added stepwise because poisonous to the mould Gas Chromatography done on each round of samples to measure methyl ester content Use n-hexane as solvent Sample is diluted 20 times Nitrogen is the mobile phase Samples were centrifuged before GC 4 peaks: methyl palmitate, methyl linoleate, methyl oleate, and methyl linolenate Methyl heptadecanoate used as interior label Time (hours) Water Content 12 24 36 48 60 72 0% 29.20 47.97 44.74 41.28 46.09 35.72 5% 23.45 45.80 65.68 72.29 72.23 71.71 10% 24.42 47.42 55.47 75.01 83.51 82.53 15% 20.12 45.58 54.84 68.37 80.18 65.09 20% 12.74 37.54 47.96 62.14 75.14 69.10 Methyl Ester Content vs. Time 90 80 Water Content Methyl Ester Content (%) 70 60 50 0% 5% 40 10% 15% 30 20% 20 10 0 12 24 36 Time (hours) 48 60 72 Control had zero peaks throughout Optimal Water Content was found to be 10% Most methyl ester produced after 60 hours One step closer to a most efficient biodiesel production process Discovering optimal conditions with cheap techniques Push towards cleaner, alternative energy Worldwide adaption Save Mother Earth! Time stages in which methanol is added How the amount of catalyst effects biodiesel Ideal amount of foam for mass transfer Best type of foaming plastic Build apparatus How functional groups play a role in mass transfer Use Jatropha seed oil Found in the Guangxi Province The skills I have gained will help me for years to come! 我所学到的技能在未来很多年都会对我有所帮助! Special Thanks to Dr. Wang Fei, Dr. Wang Yong, Dr. Moss Elica Dr. Liaw Goang, Dr. Zhang Yu,He Qiyang 特别感谢王飞教授、廖广信教授、张瑜副教授、何琦阳同学 1) Kazuhiro Ban, Masaru Kaieda, et. “Whole cell biocatalyst for biodiesel fuel production utilizing Rhizopus oryzae cells immobilized within biomass support particles”. Biochemical Engineering Journal 8 (2001) 39-43 2) Jing Zeng, Wei Du, et. “Study on the effect of cultivation parameters and pretreatment on Rhizopus oryzae cell-catalyzed transesterification of vegetable oils for biodiesel production”. Journal of Molecular Catalysis B: Enzymatic 43 (2006) 15-16 3) Yunjun Yan, Li Xu, et. “A synergetic whole-cell biocatalyst for biodiesel production”. The Royal Society of Chemistry. 2012.