Mike North

advertisement

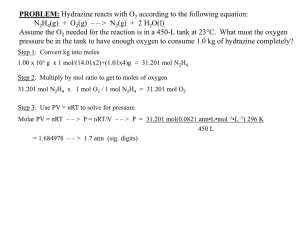

CO2 as a chemical feedstock Professor Michael North School of Chemistry Synthesis of heterocycles from epoxides All are known reactions but often with harsh reaction conditions (e.g. 20 bar CO2 pressure and >100 oC for cyclic carbonate synthesis) Could a bimetallic catalyst activate both substrates? Can we use only sustainable elements in the catalyst? Sustainable catalysis Red/orange = rising threat from increased use; Red = serious threat in next 100 years; Orange = limited availability; Many elements are endangered. http://www.chemistryinnovation.co.uk/ A bimetallic aluminium(salen) catalyst N t OH Bu t Bu N t HO t Bu Bu Al / EtOH, I2 (cat) then H2O (salen)Al O Al(salen) 1 bimetallic catalyst M. North et al., Eur. J. Inorg. Chem. 2007, 3323–3326; Chem. Eur. J. 2010, 16, 6828–6843; Patent WO/2008/132474. Cyclic carbonate synthesis from terminal epoxides O O CO2 (1 atmosphere) / 1 (2.5 mol%) / Bu4N+Br- (2.5 mol%) room temperature, 3h, no solvent O R O R R Yield R Yield R Yield Ph PhCH2 Bu C8H17 62% 44% 87% 64% Me H CH2OH CH2Cl 77% 76% 36% 60% CH2OCOMe CH2OCOPh CH2OPh CH2OtBu 50% 58% 55% 50% M. North et al., Eur. J. Inorg. Chem. 2007, 3323–3326; Chem. Eur. J. 2010, 16, 6828–6843. Supported catalysts Br Et2(Bn)N Br t N N Et2(Bn)N Br N N O O O O Br Al Al O t N N t n N(Bn)Et O O O N Al O N t Bu Bu Br Br Et2N Br Bu O Al support t Bu N(Bn)Et2 Et2N N(Bn)Et2 Bu-catalyst support = polystyrene (PS), n = 1 all other supports, n = 3 Br silica N(Bn)Et2 3 H-catalyst Results with supported catalysts Support Yield tBu-silica 69% tBu-MCM-41 (silica) 57% tBu-Solgel (silica) 52% tBu-Aluminium pillared clay 21% O O O O Ph Ph M. North et al. Patent WO/2009/109765; Chem. Commun. 2009, 2577–2579; Dalton Trans. 2011, 40, 3885–3902 Gas phase flow reactor Column dimensions: 3-15 cm x 1 cm. M. North, et al. Chem. Eur. J. 2009, 11454–11457; Dalton Trans. 2011, 40, 3885–3902 Continuous flow results o at 60 C Catalyst / support Catalyst mL / min amount CO N 2 2 evaporation % CO2 TOF rate EO consumed (h-1) tBu-silica 2.17 g 1.0 2.5 0.15 mL/h 97 2.6 tBu-MCM41 1.57 g 1.1 2.5 0.15 mL/h 95 8.3 tBu-solgel 1.94 g 1.0 2.5 0.15 mL/h 97 5.2 tBu-PS 1.94 g 1.0 2.5 0.15 mL/h 63 2.6 H-silica 2.17 g 1.0 2.5 0.15 mL/h 98 1.1 In each case, CO2 is 21% of the gases passing into the reactor. Ethylene oxide (EO) flow rate ca 1.2 mL / min. Column length 15 cm M. North, et al. Chem. Eur. J. 2009, 11454–11457; Dalton Trans. 2011, 40, 3885–3902. Continuous flow results with tBu-silica catalyst at 100 oC 3cm reactor containing 0.65g catalyst. Catalyst reactivated with BnBr %CO2 absorbed 16 14 12 10 8 6 4 2 0 1 2 3 4 5 time (days) 6 7 M. North, et al. Chem. Eur. J. 2009, 11454–11457; Dalton Trans. 2011, 40, 3885–3902 8 Doosan Power systems test facility Flue gas composition Flow rate 20 mL/min Gas T 53 oC CO2 5% Coal 52 oC 15% O2 9% 3% SO2 26ppm 291ppm CO 189ppm 40ppm NOx 33ppm M. North et al. Energy Environ. Sci., 2011, 4, 4163–4170. 443ppm Used El Cerrejon coal (typical hard coal): 74%C; 0.5%S; 1.5%N; 5%H; 7% H2O Real flue gas flow reactor results with ethylene oxide TOF (h-1) 1.2 control combined 8 and 16 h coal 0.8 Catalyst reactivated 0.4 0 0 3 6 Time (days) M. North, et al. Energy Environ. Sci., 2011, 4, 4163–4170. 9 12 Synthesis of di- and trithiocarbonates R1 R2 50 oC yield A:B 90 oC yield A:B CH3 CH2Me (CH2)3Me (CH2)5Me H H H H 97 54 56 61 89:11 85:15 66:34 70:30 94 90 87 81 5:95 47:53 43:57 39:61 CH2Cl H CH2OPh H (CH2)4 76 97 35 85:15 84 97:3 87 58:42 76 36:64 71:29 19:81 Ph 62 0:100 91 0:100 H M. North, et al. Synlett 2010, 623–627; J. Org. Chem. 2010, 75, 6201–6207. Stereochemistry • Internal epoxides are substrates. • Reaction involves inversion of epoxide stereochemistry. M. North, et al. J. Org. Chem. 2010, 75, 6201–6207. Oxazolidinone synthesis 1 Cocatalyst Conv. A:B 5 mol% 2.5 mol% 2.5 mol% Bu4NBr Bu4NBr 86% 63% 37% 18% 1.8:1 2:1 1:1.8 1:0 2.5 mol% 2.5 mol% 2.5 mol% Et3N DMAP Ph3PO 38% 24% 29% 1:8.5 1:5 3.1:1 2.5 mol% PyNO 64% 1:1.1 Best conditions eventually found to be 5 mol% 1 at 80 oC in toluene for 24 h with no cocatalyst. Gave 100% yield with A:B = 2.2:1 Other epoxides and isocyanates Acknowledgements Dr. Riccardo Pasquale Dr. Jaisiel Melendez Dr. Pedro Villuendas Dr. Carl Young Professor Bill Clegg Dr. Ross Harrington EPSRC, TSB, SSE DoosanBabcock CarbonConnections Newcastle University