Slide Show

advertisement

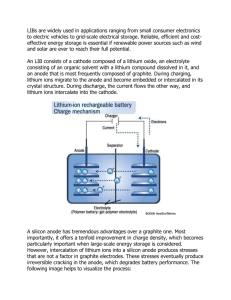

Polymers for batteries References: LiCoO2: http://en.wikipedia.org/wiki/Lithium_cobalt_oxide Nanomaterials: Angew. Chem. Int. Ed. 2008, 47, 2930 – 2946 Lead acid battery: http://en.wikipedia.org/wiki/Leadacid_battery 1 Zinc-Copper cells are the classic battery: copper plates out on the zinc during use. Volta’s cell (replica) Crow’s foot style These images and much more information are found at: http://w1tp.com/mbatt.htm Used with permission Such batteries have been know for ~200 years. 2 The lead acid battery is more common than conventional. Anode (Ox) PbSO4 + 5H2O PbO2 + 3H3O+ + HSO4- + 2e- Cathode (Red) PbSO4 + H3O+ +2e- Pb + HSO4- + H2O +1.685V -0.356 V Anode & cathode are both made of Pb/PbO2 but one is “tricked” into being brownish PbO2 (+ terminal) and the other grayish Pb (- terminal) on the surface. Both plates contain holes which hold a paste of Pb3O4 and other stuff to prevent crystal growth of PbSO4 and ensure high surface area. The energy density of the lead battery is low, due to its great weight. The power density is high, though: a lead battery can produce awesome current. Most interesting for polymer people: the separators (green in figure above). PVC or PE are used for separators—better than wood originally used, but why not PBZT? http://en.wikipedia.org/wiki/Lead-acid_battery 3 What gels in H2SO4? So…separators made of PBZT/H2SO4 gel would yield a leadacid battery that would not spill. Why didn’t we hawk this idea to the Navy for submarine use 25 years ago? 4 Here is awesome current on display. MR2 http://www.youtube.com/watch?v=GcQ8Mr_wcTQ Porsche 911 http://www.youtube.com/watch?v=ImWMKa8ZTq8 Lawn care, complete with plastic housing http://neutonpower.com/ Lawn care, old school metal housing http://www.amazon.com/Earthwise-60020-20Inch-CordlessElectric/dp/B000WEOQP4/ref=sr_1_4?ie=UTF8 &s=home-garden&qid=1273119539&sr=8-4 Change you can believe in. 5 So American tinkerers—when not cleaning up oil slicks and drilling to make new ones–play with 40-year-old German cars and 200-year-old lead acid battery technology. What’s going on in countries that have a plan? Failure to plan = planning to fail. Eliica Japanese LiIon car vs. Porsche http://www.youtube.com/watch?v=L7zHcvDPxYU Germany’s plan for 1 million EVs by 2020 http://www.msnbc.msn.com/id/23922063 Japanese 3-minute (half-amps) battery charger (batteries charging batteries, I think) http://blogs.edmunds.com/greencaradvisor/2 010/05/firm-says-its-made-system-that-canrecharge-evs-batteries-halfway-in-3minutes.html What’s interesting about this is that, even in an application where mass is not a factor, they went with Li-ion. 6 Well, Goliath did lose to David. http://www.altairnano.com/profiles/investor/fullpage.asp?f=1& BzID=546&to=cp&Nav=0&LangID=1&s=0&ID=10724 US has made enormous investments in nanotechnology that may help, but will we commercialize it, or give it away like the LCD to pursue other interests? How long are we willing to wait for profits? Most of the countries that are nipping at our heels still experience bone-crushing poverty for major sectors of their population. 7 “The rechargeable lithium battery does not contain lithium metal. It is a lithium-ion device, comprising a graphite negative electrode (anode), a nonaqueous liquid electrolyte, and a positive electrode (cathode) formed from layered LiCoO2 (Figure 1).” Anode Cathode “On charging, lithium ions are deintercalated from the layered LiCoO2 intercalation host, pass across the electrolyte, and are intercalated between the graphite layers in the anode. Discharge reverses this process.” Bruce, Scrosati & Tarasacon, Angew. Chem. Int. Ed. 2008, 47, 2930 – 2946 DOI: 10.1002/anie.200702505 8 Enormous challenges remain. First-generation lithium-ion battery: *electrodes made of powders containing millimeter-sized particles *polypropylene separator with millimeter-sized holes (…containing the electrolyte). *high energy density, but low-power density slow charge/discharge *new intercalation hosts for electrodes can help, but the slow diffusivity of the lithium ion in the solid state (ca. 108 cm2 ·s-1) limits discharge/recharge rates. About 100 times slower than small ions in liquids. “…an increase in the charge/discharge rate of lithium-ion batteries of more than one order of magnitude is required to meet the future demands of hybrid electric vehicles and clean energy storage.” 9 Going to nanometer-scale solves some problems. Some I don’t understand: “(nanoparticles) enable…reversible lithium intercalation into mesoporous -MnO2 without destruction of the rutile structure.” Some are pretty obvious: tdiffusion = L2/2D Microscale to nanoscale a million times faster! High specific surface area goes with smaller particle sizes. 10 Nanometer scale creates new problems, too. Worsened side reactions, due to extra surface area. Packing issues—nanopowders are less dense than micropowders. Nanoparticles may be harder to make reliably. 11 Lithium must intercalate into the electrodes, not deposit on it. Deposition of lithium metal on the higher specific surface area of nanoparticles could be catastrophic. Lithium in water: http://www.youtube.com/watch?v=8ypUVpwgcAA&NR=1 Would other alkali metals be better/worse? Other elements besides lithium (watch to end): http://www.youtube.com/watch?v=uixxJtJPVXk 12 It seems natural to wonder whether carbon nanotubes ought to replace graphitic carbon. The answer is no, due to lithium deposition issues. “Carbon nanotubes do not seem to offer a major route to improved electrodes.” Various lithium titanates and titanium dioxides are more promising. Also other metal oxide fiber formers. Looks like fairly serious materials science: “Nanotubes/nanowires composed of TiO2-(B), the fifth polymorph of titanium dioxide, retain the advantages of Li4Ti5O12 : low cost, low toxicity, high safety, and an electrode potential that eliminates lithium plating.” Fibers are preferred because one long dimension ensures good electrical connectivity, while two thin dimensions means the intercalation involves just a few layers—no wasted mass. 13 One way is to electroplate rods through, essentially, Anotop filters. Dissolve the filter & coat with metal alloy as electrode material. 14 Problem: the electrode materials should not experience large changes in volume on charge/discharge. Leads to cracks or “pulverization” after many cycles. Nanometer-scale particles seem to help with this— probably the up side to that low density mentioned earlier. The Bruce, Scrosati, Tarascon article is actually organized from “left” to “right” across a Li ion cell—e.g., Anode, Electrolyte, Cathode. I have lumped the edges into “electrode”. The Cathode chemistry and Anode chemistry clearly differ, but concerns about porosity, mechanical stability, etc. must be similar. 15 Enough already about the electrodes. What about the electrolyte? Liquid electrolytes are sometimes used (non-aqueous!). Addition of nanometer-scale powders (Al2O3, SiO2, ZrO2) surprisingly helps in this case. In such “soggy sands” apparently the balance between free ions and ion pairs is favorably altered. The future is in dry electrolyte/separators or Solid Polymer Electrolytes And you thought SPE was Society of Plastics Engineers. Or maybe you thought Society of Petroleum Engineers 16 Poly(ethyleneoxide) is also known as poly(ethylene glycol) or Carbowax. Soluble in H2O, Benzene, methanol, DCM Insoluble in diethyl ether & hexane Toxic to kidney (due to impurities or on its own?) if applied to skin. If you live to be 50, you’ll get to drink some! Anyway, for SPEs you dissolve lithium salts into PEO. Typically, one uses LiBF4. 17 PEO has its problems for Li-ion batteries. Conductivity of Li ion is only high at T > 70oC. Al2O3, SiO2, ZrO2 again help (possibly due to inhibition of PEO crystallization at lower temperatures). May we expect someone has looked into branching then? 18 But maybe crystals (of the salt itself) aren’t so bad. PEO Chains PEO Chains AsF6 PF6- anion is also used; here, AsF6- is used; astatine belongs to the same group as phosphorous. You have to wonder: How would a PEG-ylated polypeptide LC perform? 19 Lithium doesn’t grow on trees. The lithium battery craze carries its own environmental risks: http://www.dailymail.co.uk/home/moslive/article-1166387/In-search-Lithium-The-battle-3rd-element.html + http://en.wikipedia.org/wiki/Salar_de_Uyuni And speaking of craze…check out the pattern on the floor of Boliva’s Salar de Unuye; Bolivia is resisting development to avoid the damage caused in Chile. The Salar de Unuye is one of the largest mirrors on earth when water coats the desert floor. Salar de Unuye and Salar Coipasa from space. The former is 25x bigger than the Bonneville salt flats. Square kilometers are flat to +/- centimeters. There are alternatives to the Li-ion battery—e.g., methanol fuel cells. 20 Or we could just continue to burn oil. http://www.districtofcolumbiadispatches.blogspot.com/ http://www.deseretnews.com/article/700027439/Ro bot-subs-key-to-oil-spill-cleanup.html 21