Fatty amines and fatty amine ethoxylates

advertisement

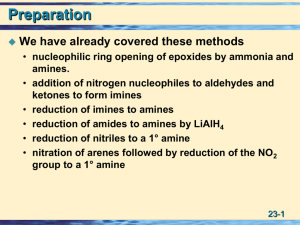

Sarah Lundgren Tribo Days 6-8 November 2012 Organic friction modifiers in engine oils – Fatty amines and fatty amine ethoxylates Overview -What is AkzoNobel Surface Chemistry’s Fatty Amine Chemistry -Ongoing investigations - Friction and wear of fatty amines and fatty amine ethoxylate -Summary Petroleum and Water applications AkzoNobel’s position in the Lube Oil Additive Market Surface Chemistry | Lubes & Fuels 3 AkzoNobel Surface Chemistry Fatty Amines Process Overview Neo-Fat® Armid® Amidation Raw Materials: Animal Based Fats Vegetable Based Oils Fat Splitting Distillation Nitrilation Esterification Quaternization Arquad® Ethoquad® Armosoft® Armolube T® Armeen® Duomeen® Triameen® Hydrogenation Alkoxylation Ethomeen® Propomeen® Ethomid® Ethofat® Oxidation Oxidation Aromox® Half Crude Gly. Petroleum and Water applications Petroleum and Water applications A world of Fatty Amine Derivatives Ethomeen Propomeen Triamine Duomeen Triameen Tetrameen Tetraamine Petroleum and Water applications Diamine Chemistries O OH N R NH R + NH N 2 N OH ed diamine Diamine HO + CH3 uaternary OH + R N OH CH3 2 Cl N CH3 CH3 Trimethyl diamine diquaternary DuomeenEthoxylated T Duomeen TTM NH R Also ethoxylate di, tri and tetra amine chemistries CH3 N CH3 CH3 + CH3 N CH 3 CH3 NH2 O 2 O 2 Cl R + NH2 R' + NH3 Diamine salt Duomeen TDO Petroleum and Water applications Fatty chain OH N OH Fatty chain Tallow, oleyl, coco, and erucyl Coco (12) Tallow (18) Erucyl (22) Longer chain Oleyl (95%) Tallow (46%) 18 (0%) Less unsaturation Petroleum and Water applications Ongoing research Two long term investigations in-house • Screening of existing products (catalogue) and new in the MTM in combination with ZDDP only • Fundamental understanding of friction modifiers in oil – both in bulk and at surfaces Many additives in an oil and a lot interactions taking place. Beginning with interactions of amine friction modifiers and antiwear additive ZDDP Petroleum and Water applications Samples • A primary / secondary blend of ZDDPs (0.5wt%) • Group III base oil from Nesteoil • 0.5wt% FM Petroleum and Water applications Background ZDDP Distribution of ZDDP antiwear film Patchy film 81GPa 25GPa 10-100nm 150nm Properties – hardness Chemical composition(3) • Increasing hardness closer to the surface • Alkyl phosphate precipitates rinse off with solvent. 25-40GPa Alkyl phosphate precipitates • Long chains • Short chains Zinc Sulphide 90GPa ZnS (1) Warren et el, Trib. Letters, 4 (1998) 189 (2) Graham et al. Trib. Letters 6 (1999) 149; Nicholls et al. Trib. Internat. 38 (2005) 15 (3) Bec et al. Proc. R. Soc. London, 455 (1999) 4181 (Poly)phosphate Steel surface Petroleum Applications Techniques for measuring friction and wear Valve Train Journal Bearings Hydrodynamic lubrication Mixed lubrication Boundary lubrication Friction Coefficient Piston Rings Oil Film Thickness/Surface Roughness (or N/P) 12 Techniques Minitraction machine (MTM) with film thickness measurement • The MTM is run with 120C, 20N and a slide roll ratio of 50%. • Measure at constant speed (200mm/s), load and temperature for two hour but stop for Stribeck curves at 0, 15, 30, 60 and 120 min. • A lot of data, here we show the Stribeck curve after two hours and the friction vs time curves. High frequency reciprocating rig (HFRR) • The HFRR is run at 120 C, 400gram, 50Hz with stroke length of 1mm. • Here we report wear scar data. µ Time Petroleum and Water applications Changes backbone and head group - Adding methyl groups to an amine increases the friction. - Secondary amine performs worse than primary. -It is worse to change the head group than the hydrocarbon chain. Perhaps two chain per molecule helps with the packing. R NH R Secondary amine Petroleum and Water applications Number of EO groups and comparison to PO groups OH R Increased degree of ethoxylation increases the friction. N OH Propoxylate worse than ethoxylate. O R m N H Not all friction modifiers reduce friction compared to ZDDP. OH O n H R N OH Petroleum and Water applications O Number Hof amines OH R N CH3 CH3 N N + + R OH N OH 2 Cl Increasing from one to two amines OH increased the friction. HO Ethoxylated diamine Methyl groups on diamine increases friction. NH R Ethoxylated NHdiquaternary NH R 2 N N NHR 2 Diamine CH 3 Salt of oleic acid and diamine better than only diamine. CH3 R + N CH3 + CH3 N CH 3 CH3 CH3 CH3 O Trimethyl diamine R' 2 O 2 Cl R + NH2 + NH3 Three amine groups performs really well. Diquaternary Diamine salt Petroleum and Water applications Film thickness All friction modifiers reduce the antiwear film thickness. A thin film usually provide low friction. A disturbance in the antiwear film formation does not have to result in increased wear. ZDDP Armeen DMTD 311µm 242µm Duomeen T Ethomeen T 197µm 219µm Armeen T 246µm Petroleum and Water applications Summary -ZDDP anti wear films show high friction giving a negative effect on Fuel Efficiency. -Early work suggests that optimal choice of Fatty Amine Chemistries can bring benefits in reduction of friction and film thickness -Most amines tested reduce friction in boundary and mixed -Methyl Groups on amine and diamine and Ethoxylates on amine perform worse than only amine. Two hydrocarbon chains worse than one. But changing head groups worse than fatty chain. -Diamines show an increase in friction compared to primary Amines. Adding oleic acid to diamines is better than without. Triamine show better performance than primary amine and this product is the best performing candidate presented. All FMs lower the film thickness compared to ZDDP. However, this does not result in poorer wear protection. Petroleum and Water applications Thank you for your attention! Petroleum and Water applications