NADH - Michigan State University

advertisement

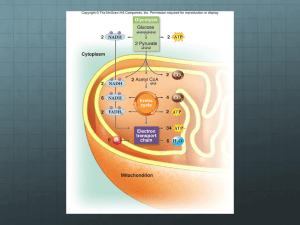

High-rate cofactor regeneration at nanostructured interfaces for bioelectrocatalysis Hanzi Li Comprehensive oral presentation Advisor: Dr. Scott Calabrese Barton Department of Chemical Engineering and Materials Science Michigan state University Nov 1 , 2011 Introduction and background 2 Dehydrogenase-based electrochemical conversion • Dihydroxyaceton(DHA): Sunless tanning cream; Precursor to pharmaceuticals • Mannitol: Natural sugar alcohol sweetener; Additive to food and pharmaceuticals Why electrode: Cofactor electrochemical regeneration Dual Chamber Catalysis eNAD+ GlyDH Glycerol Power supply NADH DHA MtDH Fructose NADH Anode Mannitol NAD+ Cathode 3 Cofactor electroregeneration • Thermodynamically, NADH oxidation should be observed at low potential. Enzyme Substrate NAD+ Product NADH NAD+ N A D H N A D 2e H electrode -0.49 V/Ag|AgCl at pH 6 CRC Handbook of Chemistry and Physics, 91st ed.; Haynes, W. M., Ed.; 2010. 4 Cofactor electroregeneration • Direct NADH oxidation requires high overpotential; Reaction rate is low. E0’ = -0.49 V/Ag|AgCl at pH 6 NADH NAD+ 50 2 Typical planar electrode: Glassy carbon electrode ( 3 mm diameter) Current density (µA/cm ) 60 40 30 20 10 0 -10 Glassy carbon Electrode -0.2 0.0 0.2 0.4 0.6 0.8 1.0 1.2 Potential (V) vs. Ag/AgCl • Cyclic voltammograms in 0.5 mM NADH at glassy carbon electrode, 50 mV/s, 0.1 M PBS, pH 6 CRC Handbook of Chemistry and Physics, 91st ed.; Haynes, W. M., Ed.; 2010. 5 High-performance cofactor regeneration NADH NAD+ • Achieve high-rate kinetics for NADH oxidation by electrode modification Electrode • Analyze the conversions in NADH oxidation using modified electrode as working electrode 6 Bioelectrocatalysis involving cofactor regeneration catalyst ox Substrate NADH Anode Enzyme catalyst red NAD+ Product • Evaluate bioelectrocatalysis based on NADH electrocatalysis • Model glycerol oxidation and fructose reduction coupled with cofactor regeneration 7 Part 1 Electropolymeried azine electrodes modified with carbon nanotubes for NADH oxidation th 8 Electrode modification NADH NAD+ High-surface area material to increase active site density NADH NAD+ NADH High surface area material NAD+ Glassy carbon Electrode Glassy carbon Electrode Catalyst ox Electrocatalyst NADH to decrease activation energy Catalystox NAD+ Catalystred Catalystred High-surface area material Glassy carbon Electrode Glassy carbon Electrode 1. Gorton, L.; Dominguez, E. J Biotechnol 2002, 82, 371. 2. Zhao, X.; Lu, X.; Tze, W. T. Y.; Wang, P. Biosensors and Bioelectronics 2010, 25, 2343. 3. Villarrubia, C. W. N.; Rincon, R. A.; Atanassov, P.; Radhakrishnan, V.; Davis, V. ECS Meeting Abstracts 2010, 1001, 443. 9 Modify electrode with CNT • CNT-GC: CNT were coated on glassy carbon electrode surface (3 mm diameter RDE) by drop-casting 5 µl CNT ink on the surface of GC electrode and drying in vacuum. Carboxylated CNT (Nanocyl) Drop Casting CNT ink Glassy carbon Electrode SEM image of CNT on electrode surface http://www.nanocyl.com/ 1. Li, H.; Wen, H.; Calabrese Barton, S. In Electroanalysis, 2011. 2. Wen, H.; Nallathambi, V.; Chakraborty, D.; Calabrese Barton, S. Microchim. Acta, 1. 10 CNT-GC: High-surface area material Active surface area / Geometric surface area (Assuming 25 µF/cm2) (mF/cm2) Capacitance in 1 M sulfuric acid 1600 40 1400 1200 30 1000 800 20 600 400 10 200 0 0.0 0.2 0.4 0.6 0.8 2 CNT Loading (mg/cm ) 1.0 0 0.0 0.2 0.4 0.6 0.8 2 CNT loading (mg/cm ) 1. Barton, S. C.; Sun, Y.; Chandra, B.; White, S.; Hone, J. Electrochemical and Solid-State Letters 2007, 10, B96. 2. Kinoshita, K.; Carbon: Electrochemical and Physicochemical Properties; 1st ed.; Wiley-Interscience, 1988. 11 Coat electrocatalyst: Electropolymerization Toluidine Blue O Poly(azine) oxPoly(azine) red Methylene Green CNT Glassy carbon Electrode Cyclic voltammograms of PTBO (Right: Top) and PMG (Right: Bottom) electropolymerization on 0.85 mg cm2- CNT-coated GC, 20 cycles, 50 mV/s, 0.4 mM TBO, 0.01 M borate buffer pH 9.1, 0.1M NaNO3, 30 ºC 1. Karyakin, A. A.; Karyakina, E. E.; Schuhmann, W.; Schmidt, H. L. Electroanalysis 1999, 11, 553. 2. Zeng, J.; Wei, W.; Wu, L.; Liu, X.; Liu, K.; Li, Y. Journal of Electroanalytical Chemistry 2006, 595, 152. 12 NADH electrocatalysis NAD+ NADH N AD H Pox N AD Pred H i k N AD H , ads Pox Poly(azine) Poly(azine) red ox CNT Glassy carbon Electrode N A D H , ads P ox exp (V U ) / b C NADH i im ax K C 1 exp ( V U ) / b NADH S 1. Kar, P.; Barton, S. C. ECS Meeting Abstracts 2010, 1001, 405. 2. Karyakin, A. A.; Karyakina, E. E.; Schuhmann, W.; Schmidt, H. L. Electroanalysis 1999, 11, 553. 13 NADH electrocatalysis a&c: PTBO ; b&d: PMG 1: Bare GC; 2: 0.21 mg/cm2 CNT-GC; 3: 0.85 mg/cm2 CNT-GC NADH concentration study of PTBO-CNT-GC (a) and PMG-CNT-GC (b) at 50 mV/Ag|AgCl; Polarization curves of PTBO-CNT-GC (c) and PMG-CNT-GC (d) in 0.5 mM NADH. 0.1 M phosphate buffer pH 6.0, 900 rpm, 30 ºC. Markers: Experimental data; Solid line: Fitting using mass-transport corrected model; Dash line: Simulation for mass-transport corrected curves. 14 NADH electrocatalysis exp (V U ) / b C NADH i im ax K C 1 exp ( V U ) / b NADH S Electrodes imax (mA/cm2) PTBO-0.21 mg/cm2 CNT-GC 4.2 ± 0.8 PTBO-0.85 mg/cm2 CNT-GC 8.4 ± 1.9 PMG-0.21 mg/cm2 CNT-GC 15 ± 3.2 PMG-0.85 mg/cm2 CNT-GC 26 ± 4.1 15 Part 2 Analysis of the bulk rate of cofactor electroregeneration 16 CNT modified carbon paper (Toray) Active surface area / Geometric surface area (Assuming 25 µF/cm2) Capacitance was obtained in 0.01 M borate buffer pH 9.1, 0.1 M NaNO3, 30 ºC 17 NADH Oxidation Using PMG-CNT-Toray • CNT-Toray: CNT were coated on carbon paper surface (2.5×2.5 cm2) by air-brushing 2 mg ml-1 CNT ink on the surface and drying in vacuum. • 1.2×0.8 cm2 (Exposed surface area 1.0×0.8 cm2 , CNT loading 0.9 ± 0.1 mg/cm2) CNTToray was used for further modification and working electrode. Batch reactor to study the conversion PMG-CNT acts as electrocatalyst for NADH oxidation Carbon Paper NADH CNT-PMG NAD+ NADH oxidation was performed with initial NADH concentration 0.94 mM in 20 ml pH 6 phosphate buffer, constant applied potential 0.5 V/ Ag|AgCl, 1200 rpm magnetically stirred, 30 ºC. 18 Conversions in NADH bulk oxidation NADH consumption: rN A D H relectro rdecay Electrocatalysis: N AD H C atalyst ox N AD C atalyst red H relectro j A nF V exp (V U ) / b j m ax A C NADH nF V K S C N A D H 1 exp (V U ) / b Decay rN A D H d eca y kC N A D H k=(1.0± 0.1 ) ×10-3 min-1 NADH concentration profile can be simulated. 19 Conversions in NADH bulk oxidation 1.0 1.0 0.8 0.6 0.6 + 0.8 NAD concentration / mM NADH concentration / mM a NADH concentration 0.4 Expected NAD + 0.2 0.4 0.2 0.0 0.0 0 20 40 60 80 100 120 140 Reaction time / min NADH concentration was measured using UV-Vis spectra during NADH bulk oxidation C Expected _ N AD ,t C N AD H t 0 C N AD H m easured , t C N AD H decayed , t 20 Enzyme cycling assay for detecting bioactive NAD+ • During electraocatalysis and after electrocatalysis, enzyme assay was employed for bulk solution Initially: LDH, Lactate, Diaphorase, Pyruvate MTTox MTTox NAD+ Diaphorase LDH Lactate MTTred NADH www.bioassaysys.com Very fast A5 6 5 , Relatively slow t ([ N A D H ] [ N A D ]) in the solution 21 Bioactive NAD+ C Active _ N AD ,t C ( Active _ N AD N AD H ),t C N AD H m easured , t C Expected _ N AD ,t C N AD H t 0 C N AD H m easured , t C N AD H decayed , t 0.8 + Enzymatically active NAD / mM 1.0 0.6 0.4 0.2 0.0 0.0 500 mV / Ag|AgCl 150 mV / Ag|AgCl 0.2 0.4 0.6 0.8 1.0 + Expected NAD / mM Applied potential Yield of NAD+ at end (%) 500 mV 88 ± 2.3 150 mV 82 ± 3.6 22 Part 3 Immobilization of enzymes and cofactors on poly(azine)-CNT modified electrodes to achieve high-performance bioelectrocatalysis 23 N6 –linked-NAD+/NADH by Vieille Lab NAD+ Aryl amine Lindberg, M.; Larsson, P.-O.; Mosbach, K. European Journal of Biochemistry 1973, 40, 187 24 Electrochemical activity of N6-linked NADH Typical RDE Set-up 40 µl - Electrolyte Set-up ω electrolyte electrode electrode electrolyte 40 µl, Room temperature 0.02 µmoles NADH is needed for 0.5 mM solution 900 rpm, 30 °C, At least 10 ml solution, Purged Ar 5 µmoles NADH is needed for 0.5 mM solution 25 Electrochemical activity of N6-linked NADH Polarization curves Steady-state data from chronoamperometry , pH 6 PBS, Standard NADH solution: 0.5 mM RDE New set-up Current density / µA cm -2 8 6 4 2 0 -0.1 0.0 0.1 0.2 0.3 0.4 0.5 E / V | Ag/AgCl • The lower activity may due to o Limited mass transport o O2 present • Can be fixed by o Compare RDE data in 0 rpm and in air o (Experiment in N2 or Ar) 26 Biosensor based on electronic interface catalyst ox Malate NADH Anode MDH catalyst red NAD+ Oxaloacetate Reference electrode Kinetics: Step 1 relectro Step 2 renzyme N A D H NAD electrode M alate N A D O xaloacetate N A D H MDH • Evaluate the whole process by monitoring the responding current 27 Biosensor towards malate concentration 100 Current density / µA cm -2 80 60 #1 Electrode #2 Electrode 40 20 0 0 50 100 150 200 250 300 Malate Concentration / mM PMG-CNT-GC, chronoamperometry , E=0.4 V vs. Ag|AgCl, 900 rpm, pH 6 PBS, 30 oC, MDH 0.83 µM, initially NAD+ 10 mM • Start with free diffusing cofactor, MDH and malate, will be extended to immobilized cofactor/MDH (immobilization method by Worden Lab) 28 Back-up plan for cofactor/enzyme immobilization • Cofactor is non-covalently attached to CNT via π-π stacking interaction Zhou, H.; Zhang, Z.; Yu, P.; Su, L.; Ohsaka, T.; Mao, L. Langmuir 2010, 26, 6028. CVs obtained at the MWCNT-modified Pt electrodes in 0.1 PBS buffet before (blue curve) and after (black curve) at the electrodes were first immersed into the aqueous solution of 10 mM NAD+ for 1 h and then thoroughly rinsed with distilled water. Scant rate: 50 mV/s. Inset: structure of NAD+ cofactor . 29 Part 4 Model glycerol oxidation and fructose reduction coupled with cofactor regeneration 30 Linear model NADH Anode catalyst ox catalyst red Glycerol GlyDH NAD+ Dihydroxyacetone (DHA) X=0 X=l Mass balance involving kinetics and diffusion within film : 2 N AD N D Nh renzym e 2 t x G lycerol t D G ly 2 G ly x 2 Steady-state within film : D Nh D G ly d 2 N dx d 2 2 renzym e G ly dx 2 renzym e renzym e Boundary conditions: x0 d G ly 0 dx d N AD j m ax [ N h ] x 0 exp((V U ) / b ) 1 dx K N h [ N h ] x 0 1 exp((V U ) / b ) nF x l [ G lycerol ] [ G lycerol ] d N AD 0 dx 31 Non-dimensionalization x0 2 d N dw 2 Da N AD r ' enzym e dG 0 dw dN dw D aa relectro ' NAD 2 d G dw 2 D a G lycerol renzym e ' xw dN 0 dw G 1 Damkohler numbers Da N AD k catf [ E ] L D N AD [ N AD H ] 0 D a G lycerol D aa NAD 2 k catf [ E ] L 2 D G lycerol [ G lycerol ] j m ax L exp((V U ) / b ) 1 D N A D [ N A D H ] 0 1 exp((V U ) / b ) nF Kar, P.; Wen, H.; Li, H.; Minteer, S. D.; Barton, S. C. J. Electrochem. Soc. 2011, 158, B580. 32 Porous model Boundary conditions: Mass balance: x0 2 d N dw 2 Da renzyme D aa ' NAD r elelctro ' NAD dG 0 dw dN 0 dw 2 d G dw 2 D aGlycerol renzyme ' x l dN 0 dw G 1 33 Parameters Parametera NADH concentration, [NADH]0 Glycerol bulk concentration, [Glycerol]∞ Reactor volume, Vol Electrode geometric surface area, cm2 Enzyme concentration, [Enzyme] Equilibrium constant for enzyme reaction, Keq Turnover number of glycerol oxidation, kf Turnover number of DHA reduction, kr Michaelis-menten constant for NAD+, KmA Michaelis-menten constant for glycerol, KmB Michaelis-menten constant for NADH, KmQ Michaelis-menten constant for DHA, KmP Dissociation constant of NAD+, Kia Dissociation constant of glycerol, Kib Dissociation constant for NADH, Kiq Dissociation constant for DHA, Kip Film thickness, L Diffusion coefficient for NADH/NAD+, DNh/DN Value 10 mM 1M 10 cm3 1 cm2 1 mM 4×10-4 9.1 s-1 9.1 s-1 12 µM 440 mM 14 µM 13 mM 1.09 mM 1.5×104 mM 25 µM 11 mM 10 µm 3.3×10-8 cm2 s-1 Source Set Set Set Set Set Vieille lab Vieille lab Vieille lab Vieille lab Vieille lab Vieille lab Vieille lab Diffusion coefficient for glycerol/DHAb, DGly 4.0×10-6 cm2 s-1 1 2 2,3 2 3 Set 1 a: parameter values regarding NADH electrocatalytic reaction have been shown in Project 1 b: assumed to be the same as methanol 1. Kar, P.; Wen, H.; Li, H.; Minteer, S. D.; Barton, S. C. J. Electrochem. Soc. 2011, 158, B580. 2. Nishise, H.; Nagao, A.; Tani, Y.; Yamada, H. Agricultural and Biological Chemistry 1984, 48, 1603. 3. Gartner, G.; Kopperschlager, G. J. Gen. Microbiol. 1984, 130, 3225. 34 Simulation results DaNAD+ = 16 Daglycerol = 0.0013; DaaNAD+ = 406; Linear model: Porous model: R A renzym e dl R A renzym e dw ' R porous 4 R linear 35 Summary • Fabricated poly(azine)-CNT-GC demonstrates high-rate for NADH electrocatalysis. • NADH bulk oxidation shows 80% conversion of 1 mM NADH in 1 hr. Bioactive NAD+ was verified. • Calibration curve for immobilized cofactor evaluation and dehydrogenase-based biosensor are proposed • Nondimensional Damkohler numbers can provide useful approach to simulate, predict and evaluate performance of bioreactor. 36 Thank you. 37 Supplemental information 38 Biosensor towards malate concentration • Start with free diffusing cofactor, MDH and malate, will be extended to immobilized cofactor/MDH (immobilization method by Worden Lab) 60 40 20 100 500 1000 1500 Time / s PMG-CNT-GC, chronoamperometry , E=0.4 V vs. Ag|AgCl, 900 rpm, pH 6 PBS, 30 oC, MDH 0.83 µM, initially NAD+ 10 mM 2000 80 -2 0 Current density / µA cm Current density / µA cm -2 80 60 #1 Electrode #2 Electrode 40 20 0 0 50 100 150 200 250 300 Malate Concentration / mM 39 Cystein 40 • The decay of NADH in 0.1 M phosphate buffer pH 6.0, magnetic stirred speed 1200 rpm, 30 ºC. a. At varies NADH initial concentrations, NADH decay was monitored using UV-Vis spectra at 340 nm; b. The slopes in a. varying with NADH initial concentration. 41 Acknowledgements • Collaborators • Dr. Mark Worden • Dr. Claire Vieille • Justin Beauchamp • The National Science Foundation (Award CBET-0756703) 42 Principle of LDH-MTT Assay Initially: LDH, Lactate, Diaphorase, MTTox Pyruvate MTTox NAD+ Diaphorase LDH Lactate NADH MTTred www.bioassaysys.com Very fast Relatively slow 1. When NAD+ presents in the sample, it is converted to NADH in LDH and lactate. 2. MTTox uses NADH to oxidize into MTTred. The NADH is thus converted back to NAD+. 3. The enzyme cycle starts over. Once the cycle starts, NADH concentration in the assay is not changing = [NAD]+[NADH] in the sample 43 Kinetics assay using LDH-MTT Assay Kit www.bioassaysys.com Initially: LDH, Lactate, Diaphorase, MTTox MTTox NAD+ Diaphorase LDH Lactate MTTred NADH A565 ,0 15 m in ( A565 , t 15 m in A565 , t 0 m in ) ([ M T Tred ]t 15 m in [ M T T red ]t 0 ) A565 [ M TTred ] • Pyruvate Linear kinetics within 15 mins ([ M TTred ]t 15 min [ M TTred ]t 0 ) R 15 min k [ N AD H ] 15 min 0.8 BioAssay using NAD only NADH only NAD NADH:NAD=1:1 A565 , t 0 15 m in [ N A D H ] A5 6 5 , t 0 1 5 m in ([ N A D H ] [ N A D ]) in the sample A565 0.6 0.4 0.2 0.0 0 2 4 6 8 10 Pyridine necleotide/ µM 44 Modified electrodes High-surface area electrodes for NADH electrocatalysis Data source Applied potential E vs. imax imax RHE (mV) (µA/cm2) (µA) PMG -“Bucky paper” 913 ------------ 600 (Yang and Liu 2009) PBCB-SWCNT-GC 685 ------------ 1.2 (Doaga, McCormac et al. p-DAB-MB-SWCNT-GC 663 8.49 0.6 (Zhu, Zhai et al. 2007) Meldola blue-CNT-GC 505 1.6 0.4 (Huang, Jiang et al. 2007) Thionine-CNT- 537 28.3 2 655 ------------ 45 (Villarrubia, Rincon et al. Approach 2010) 2009) Nafion/GC (Zeng, Wei et al. 2006) TBO-MWNT-GC 45 Why Mannitol? • Mannitol is a natural sugar alcohol sweetener. • Mannitol is especially useful as an additive to food and pharmaceuticals – It has low caloric and cariogenic properties – It is not metabolized by the body – It has a cool sweet taste • Currently mannitol is produced by hydrogenating a 1:1 fructose/glucose syrup – – – – – Very high temperatures, pressure and a Raney nickel catalyst Needs highly purified substrates Energy intensive Costly purification Low yield (15%) • Enzymatic catalysis reducing fructose to mannitol – Potential applications to other dehydrogenases Overall Objective • Glucose fructose using a thermostable glucose isomerase – Triple mutant of Thermotoga neapolitana xylose isomerase (TNXI 1F1) • Optimized for high activity at 60°C, and high activity at pH 6.0 while maintaining glucose activity • Fructose mannitol • NADH regeneration from cathodic current pulls reaction towards mannitol production Nicotinamide Dinucleotide Adenine 48 Literature review about NADH electrocatalytic oxidation: The reported steady-state current densities for NADH oxidation were far less than 1 mA cm-2 under low overpotentialData source Approach Applied Vmax Vmax (Palmore, Bertschy et al. 1998) (Dilgin, Gorton et al. 2007) (Radoi, Compagnone et al. 2007) (Zhang, Smith et al. 2004) (Liu, Zhang et al. 2010) (Zhao, Lu et al. 2010) (Villarrubia, Rincon et al. 2010) (Yang and Liu 2009) (Zeng, Wei et al. 2006) (Doaga, McCormac et al. 2009) (Zhu, Zhai et al. 2007) (Huang, Jiang et al. 2007) (Kim, Kim et al. 2010) Free diffusing DI+ BV-GC PTBO-GC: photoelectrocatalytic Bulk screen-printed electrodes modified with Prussian blue (PB) MWCNT-Chitosan-GC Magnetic chitosan microspheres Polythionine-GC Single-carbon fiber microelectrode with CNT PMG SWCNTs-based “Bucky paper” PBCB-SWCNT-GC TBO/MWNTs adduct-GC p-DAB-MB/SWCNTs/GC Meldola’s blue adsorbed-CNT-GC Thionie incorporated by DMF/CNTs-Nafion/GC Iron oxide/carbon black-GC potential E vs. RHE (mV) ---------- (uA/cm2) (uA) --------- ----------- 755 445 25.4 3.54 5 0.25 1037 705 85 141 6 10 1331 ------------- 1.7 913 (pH 7 solution) 685 655 663 ------------ 600 ----------------------8.49 1.2 45 0.6 505 537 1.6 28.3 0.4 2 643 16 4 49 For the reduction of U in polarization curves Take one PTBO-0.85 mg/cm2 CNT-GC and PTBO-GC as an example: Proposed reason: Impact of Mass-transport Polarization curve: 0.5 mM NADH , 900 rpm, pH 6 PBS, 30 oC Controlled 0.035 by mass-transport (not controlled by applied potential) 0.7 2 Current density (mA/cm ) 0.6 2 PTBO-0.85 mg/cm CNT-GC PTBO-Bare GC 0.030 0.5 0.025 0.4 0.020 0.3 0.015 Mixed Control (By both applied potential and mass-transport) 0.2 0.010 0.1 0.005 0.0 -0.2 0.000 -0.1 0.0 0.1 0.2 0.3 0.4 Controlled by electron-transfer rate (controlled by applied potential) 50 CNT-GC • High-surface area of CNT-GC: Good utilization of CNT 115 m2/g (capacitive surface area) vs. 80-140 m2/g (BET) • Carboxylated multiwall carbon nanotubes (CNT) instead of untreated CNT were used: hydrophilic property of COOH-CNT make it possible to utilize the good properties of CNT for electrochemical experiments • Dimethylformamid (DMF) is used as solvent to form CNT-ink: • Organic solvent, disperse CNT well; Can evaporate; Miscible in water 51 Wen, H.; Nallathambi, V.; Chakraborty, D.; Barton, S. C. ECS Meeting Abstracts 2010, 1002, 366. Characterization of PTBO and PMG films Poly(azine) oxPoly(azine) red • CV in pH 6 0.1 M PBS, 50 mV/s 30 oC CNT Glassy carbon Electrode 4 Current density (mA/cm ) 2 2 2 Current density (mA/cm ) 4 0 -2 PTBO/bare GC 2 PTBO/ 0.21 mg/cm CNT-GC 2 PTBO/ 0.85 mg/cm CNT-GC -4 -0.8 -0.6 -0.4 -0.2 0.0 E (V) vs. Ag/AgCl 0.2 0.4 2 0 -2 PMG/bare GC 2 PMG/ 0.21 mg/cm CNT-GC 2 PMG/ 0.85 mg/cm CNT-GC -4 0.6 -0.8 -0.6 -0.4 -0.2 0.0 0.2 0.4 E (V) vs. Ag/AgCl 52 0.6 • DMF: Dimethylformamid (CH3)2NC(O)H 53 Process of catalytic reaction of NADH The catalysis efficiency varies with polymers. Even though the mechanisms are not well developed, it is reported that the differences of azine chemical structures affect the electrocatalytic activity toward NADH oxidation. For instance, the additional electron acceptor groups in the aromatic ring always lead to higher electrocatalytic activity, while the additional proton donor groups cause lower electrocatalytic activity. [13, 36] Methylene green has an additional –NO2 group and toluidine blue has an additional -CH3 group. Thus PMG-modified electrodes tend to show higher activity especially at high positive potential region and high NADH concentration. 1. Qi-Jin, C. and D. Shao-Jun, Journal of Molecular Catalysis A: Chemical, 1996. 105(3): p. 193-201. 2. Cooney, M.J., et al., Energy & Environmental Science, 2008. 1(3): p. 320-337. NADH NAD H 2e Or 54 CNT-modified GC electrode: Capacitance measurement • Carbon nanotube is coated on glassy carbon electrode surface (3 mm diameter RDE) by dropcasting: Drop Casting CNT Each CNT layer: 5ug 1mg/ml CNT-DMF suspension Example of capacitance measurement: 0.50 mg/cm2 CNT loaded on GC 1.4 2 Current (mA/cm ) 2 Charging Current (mA/cm ) 1.0 0.5 0.0 -0.5 30 mV/s 50 mV/s 60 mV/s 80 mV/s 100 mV/s -1.0 0.30 0.32 0.34 0.36 0.38 1.2 1.0 0.8 0.6 0.4 Glass y carbo n Elect rode Charging current 0.2 Linear fit: slope is 12.5 mF/cm 0.0 0.40 E (V) vs. Ag/AgCl Capacitance data were obtained by cyclic voltammetry in the 0.3 to 0.4 V vs. Ag/AgCl at 0.01 M borate buffer pH 9.1, 0.1 M NaNO3, 30 oC 0 20 40 60 80 100 2 120 Scan rate (mV/s) 55 Proposed structure of Poly (MB) N H 3C N S CH3 N CH3 CH3 NO2 CH3 H 3C M e th y le n e G re e n N S H N N CH3 N H 3C N S N H 3C N CH3 S N CH3 CH3 N CH3 CH3 Karyakin, A.A., et al., 1999. 11(8): p. 553-557. 56 Imax after MT correction 25 2 imax (mA/cm ) 20 PMG-CNT-GC PTBO-CNT-GC 15 10 5 0 0.0 0.2 0.4 0.6 0.8 1.0 2 Loading of CNT (mg/cm ) 57 Effect of Mass transport MT Correction Mass balance: k CS k d (C C s ) K S CS Electrochemical experiments: i nF D C x x0 nF k d ( C C s ) Obtain i’max and K’s for pure kinetic control Solid lines : kinetic 58 Bioreactor based on electronic interface Power supply Anode GlyDH NAD+ catalyst red Referen ce electro de Glycerol NADH catalyst ox Dihydroxyaceton e (DHA) Kinetics: Step 1 r1 N A D H NAD electrode Step 2 r2 G lycerol N AD D H A N AD H H GlyDH relectro i S nF [ NADH ] K Nh [ N A D H ] k1 S nF V renzym e k cat [ E nzym e ][ G lycerol ][ N A D ] K N A D [ G lycerol ] [ G lycerol ][ N A D ] K G lycerol [ N A D ] 59 Concentration profile for substrate conversion For the whole batch reactor: d [ N AD ] dt d [ N AD H ] dt d [ G lycerol ] dt relectro renzym e Initial values: t=0, [NADH] = [NADH]0 ; [NAD+]=0; [Glycerol] = [Glycerol]0 renzym e [NADH]0=20 mM; [Glycerol]0 =100 mM; V = 20 cm3; S = 1 cm2; E = 10 µM; KNADH =7.0 mM; kcat = 9.1 s-1; Kglycerol = 11 mM KNAD+ = 25 µM; Glycerol concentration (mM) 100 80 60 40 20 0 0 2 4 6 8 10 Time (hr) 1. 3.02 hr • Key parameters: Sk1/nFV ( µM/s ) 2. [Enzyme] (µM or mM) 60 Fabrication of PMG-CNT-Toray 1. CNT-Toray: Spray-coat (air-brushing) CNT ink on Toray paper surface and dry in vacuum. Toray paper: 3.5 cm × 3.5 cm; 100 µm thickness CNT ink: 20 mg CNT dispersed in 10 ml DMF Exposed surface area of Toray to CNT ink: 2.5 cm × 2.5 cm Resulted loading: 1.1 mg ± 0.11 CNT/ cm2 Bare Toray: 0.16 m2/cm3 For 0.9 cm2 bare Toray, active surface area: 14.4 cm2 Capacitance: 608 uF/cm2 61 62 How Sk1/nFV or/and [Enzyme] impact Time constant? 30 [E] = 0.1 uM [E] = 1 uM [E] = 10 uM [E] = 100 uM 25 Zoom in 5 15 10 3 2 1 5 06 0 10 [E] = 0.1 uM [E] = 1 uM [E] = 10 uM [E] = 100 uM 4 Time (hr) Time (hr) 20 2 3 4 5 6 7 89 100 2 3 4 7 89 5 6 7 89 1000 100 2 3 4 5 6 7 89 1000 Sk1/nFV (uM/s) Sk1/nFV (uM/s) Sk1/nFV ( µM/s ) Sk1/V ( A/cm3 ) E (µM) 10 - 1000 0.002 – 0.2 1-100 63 Nondimensionalization Variables: [ NAD ] x [ N A D ]0 Nh [ NADH ] y [ N A D ]0 N [ F ructose ] f [ F ructose ] 0 Important parameters: Parameter s: F t K k cat nF K NADH 1 K N AD V [ N A D ] 0 nF S k1 [ N A D ]0 2 K F ructose [ F ructose ] 0 M dx d df d dy d rho1 K rho 2 M rho 2 M Sk 1 [ N A D ]0 [ F ructose ] 0 k cat [ E nzym e ] 1 2 K DEQs [ E nzym e ]V x N x K yf F y N h f yf yf F y N h f yf [ N AD ] 0 [ Fructose ]0 Equili brium const Time ant, const repre ants sentin for g key step opera Boundary conditions: t=0, x=1, y=0, f=1 64 Current work: Enzyme kinetics of MtDH • Ordered bi bi kinetics NADH k1 k-1 Fructose Mannitol k2 k3 k-2 NAD k-3 k4 k-4 k p E N AD H F E M N AD k p A: NADH B: Fructo V f V r ([ A ][ B ] v V r K ia K m B V r K m B [ A ] V r K m A [ B ] V f K m Q [ A ][ P ] K eq K ia V f [ P ][ Q ] K eq [ P ][ Q ] ) K eq V f K mQ [ P ] V f K m P [Q ] K eq V r K m A [ B ][ Q ] K iq 1. Segel, Irwin H. (1993). New York: Wiley K eq V r [ A ][ B ][ P ] K ip V r [ A ][ B ] V f [ B ][ P ][ Q ] K ib K eq 65 Enzyme kinetics of MtDH • Definition of parameters A: NADH B: Fructo se V K K V K K K V K K V K K P: • The values of 10 parameters Manni I extracted based on tol experimental data K ia k 1 K mA K mB K iq k1 k4k3k P k4 k 4 K mQ k1 ( k 4 k 3 k 4 k P k 4 k P k 3 k P ) k 4 ( k 2 k 3 k 3 k P k 2 k P ) K mP k2 (k4 k3 k 4 k P k 4k P k3k P ) k 1k 2 k P k 4 ( k 1k 2 k 1k P k 1k P k 2 k P ) k 1 ( k 2 k 3 k 2 k P k 3 k P ) k 3 ( k 1k 2 k 1k P k 1k P k 2 k P ) 2 f iq mP f ip mQ r ia mB r ib mA eq KmA KmB KmP KmQ Kia Kiq Vf Vr Keq 0.0371 39.89 8.06 0.0181 0.033 0.222 19.38 0.445 59.2 [P]/Kip=0 Kib 4.7e4Kip 1. Vf and Vr: U/mg; All Km’s and Ki’s: mM; Keq: dimensionless 2. For 60 oC, pH 6.1 1. Segel, Irwin H. (1993). New York: Wiley 2. Seung Hoon, S., N. Ahluwalia, et al. (2008). "Applied Microbiology and Biotechnology: 81 (3) 485-495 81(3): 485-495. 66