Obtencion of 1,2 and 1,3-PDO from glycerol - IQ

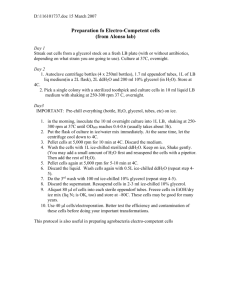

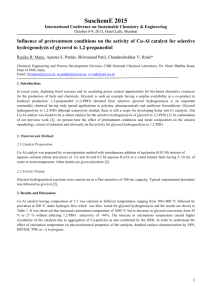

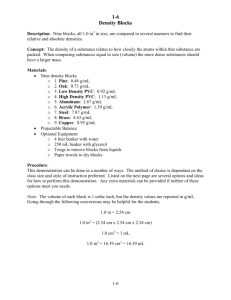

advertisement

The dwindling supply and exponential growth in the demand of fossil fuels have motivated researchers t o explore alternative resources and technologies for fuels and chemicals. The utilization of the relatively large amounts of glycerol side product (10wt.%) formed in bio-diesel manufacture is a major factor in the overall cost effectiveness of the process . Therefore, use of this glycerol as a renewable feedstock to produce value added chemicals is crucial to biorefinery economics. Descrition (or glycerin, glycerine) (C3H8O3) : is a simple polyol compound. Descrition (C3H8O2): It is a colorless, nearly odorless, clear, viscous liquid with a faintly sweet taste, hygrosc opic and miscible with water, acetone, and chloroform. Ways of obtaining:by catalytic hydrogenolysis Industry interest: industrial solvent, antifreeze, deicing agent and approved additive in food, cosmetic and ph armaceutical industries Descrition (CH2(CH2OH)2): This three-carbon diol is a colorless viscous liquid that is miscible with water. Ways of obtaining: by bacterial fermentation Industry interest: Plastics based on this monomer exhi bit better product properties and higher light stability th an those produced by 1,2-propanediol, butanediol or e thylene glycol. 1,3-Propanediol can also be used as a polyglycol-type lubricant and as a solvent. In this assignment, 1,2-PDO has been obtained with two hydrogenlysis methots. We are going to discuss the best aspects of each one The catalyst in this experiment is an admixture of 5 wt.% Pt/Al2O3 and 5 wt.% Ru/ Al2O3 . The Pt/Al2O3 was chosen to promote the aqueous phase reforming of glycerol to hydrogen , whereas Ru/Al2O3 was chosen to facilitate the hydrogenoly sis of glycerol by in situ hydrogen generated . It is demonstrate that the admixture catalyst outpe rformed the individual catalysts with respect to 1,2-PDO selectivity and yield under without added hydrogen condition. The yield of 1,2-PDO was also higher with the admixture catalyst when compared to the externall y added hydrogen condition. The results with 5% Ru/A l2O3 and 5% Pt/Al2O3 ad mixture combinations an d the monometallic cataly sts on glycerol hydrogen olysis in absence of exter nally added hydrogen at 493 K are compared in these graphs. Glycerol is converted into hydroxyacetone (reaction intermediate) through the dehydration, followed by the hydrogenation into 1,2-propanediol, with a yield over 96%. In this process, the dehydration needs relatively high reaction temperatures, whereas the hydrogenat ion favors low temperatures and high hydrogen concentration. The main catalyst is Cu/Al2O3, it doesn’t present deactivation until 200ºC and whit that, it would be obtained the best yields and selectivity The best temperatures for this process are betwee n 170 and 200ºC The production of 1,3 – PDO has been carried out us ing two bacterias: Clostridium butyricum and Klebsie lla pneumoniae The experiment includes fermentations in batch culture, fed-batch culture and continuous culture. This experiments were carried out in shake flasks and a fixed-bed bioreactor. Results showed that the NaCS/PDMDAAC microcapsule has desirable properties such as biomass enrichment in the microcapsule , enhanced substrate tolerance and stable activity of cells respect of the no encapsulated cells. Maximum concentration of 1,3-propanediol (55–60 g/L) was obtained in batch and fedbatch cultures . Continuous culture has the advantage of relatively high productivities ,however, its 1,3-propanediol concentration is not high enough to reduce the load of downstream separation. Also, there has been growing interest in a more e conomical route that utilizes glucose as a lower-co st feedstock. The great difference of this bacteria is that it present s a strong tolerance at the inhibitory effect of the 1,3propanediol and glycerol, even at high concentration s of this substance at the chemostat. It means that 1,3-PDO can be carried out with pure or industrial glycerol. A great advantage for the industry. In this assignment we have studied the production of 1,3PDO with batch, single-step and two-stage continuous cultures. The medium yield for glycol is 55%, in single-step continuous, large quantities of 1,3-PDO have been obtained with low concentrations of glycerol, however if t he flow increases, the concentration decreases of 1,3 PDO. having a second stage could be mainly used to further in crease the product concentration and to completely use t he residual glycerol.