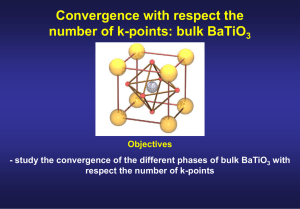

BaTiO 3

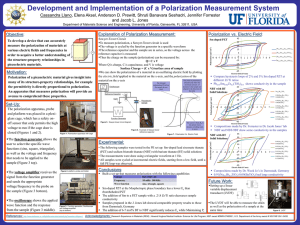

advertisement

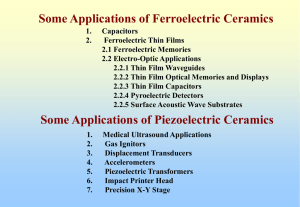

Ferroelectric ceramics Important events in the history of ferroelectrics 1824 Pyroelectricity in Rochelle salt NaKC4H4O6*4H2O (Brewster) 1880 Piezoelectricity in quartz and Rochelle salt (Jacques & Pierre Curie – quartz balance) 1912 Ferroelectricity proposed as a property of solids 1921 Ferroelectricity in Rochelle salt (Valasek) 1935 Ferroelectricity in KH2PO4 1941 High dielectric constant in BaTiO3 1944 Ferroelectricity in BaTiO3 (von Hippel, Wul & Goldman) 1945 BaTiO3 ceramics for piezoelectric transducers (electrical poling) 1949 Theory of ferroelectricity in BaTiO3 (Devonshire) 1949 Ferroelectricity in LiNbO3 and LiTaO3 1952 Phase diagram of Pb(Zr,Ti)O3 – PZT established 1954 PZT reported as a useful piezo transducer 1955 Ferroelectricity in alkali niobates 1961 PbMg1/3Nb2/3O3-PMN reported as ferroelectric relaxor 1969 Optical transparency achieved in hot pressed PLZT 1971 Useful electrooptical properties reported for PLZT 1980 Electrostrictive PMN devices developed 1992 New types of PZT piezo actuators developed 1993 Integration of FE films on silicon technology - FERAMs 1997 Ultrahigh piezoelectric coefficients in PMN-PT and PZN-PT 2002 High polarization and magnetoelectric coupling in BiFeO3 films 2004 High-performance lead free KNN piezoceramics (KxNa1-xNbO3) Important events in the history of ferroelectrics Fundamental steps in the understanding and application of ferroelectric and piezoelectric ceramics (1) The discovery of unusually high dielectric constant of BaTiO3 ( multilayer ceramic capacitors - MLCCs). (2) The discovery that the origin of the high dielectric constant in BaTiO3 is its ferroelectric nature, thus disclosing an entire new class of piezoelectric/ferroelectric materials –ABO3 perovskites with BO6 octahedra. Ferroelectricity no longer related to hydrogen bonds. (3) The discovery of the electrical poling process to align the electrical dipoles of the grains/domains within the ceramics obtaining properties similar to those of single crystals (large scale production and application of piezoelectric transducers and actuators). Piezoelectricity and ferroelectricity in solids 21 noncentrosymmetric crystal classes Optical activity (Circular Dichroism) 1 Enantiomorphism 5 5 1 Polar crystals (Pyroelectricity) 2 3 3 current 1 T Piezoelectricity Second-Harmonic Generation (SHG) Piezoelectricity and ferroelectricity in solids 7 Crystal systems - 32 Symmetry Point Groups 21 Noncentrosymmetric 11 Centrosymmetric (Non-piezoelectric) 20 Piezoelectric Polarized under stress 10 Pyroelectric/Polar Spontaneously polarized Subgroup Ferroelectric Spontaneously polarized Polarization reversible Tungsten bronze PbNb2O6 Oxygen octahedra ABO3 Layered structures Bi4Ti3O12 Pyrochlores Cd2Nb2O7 Na1/2Bi1/2TiO3 Perovskites BaTiO3 PbTiO3 PT Pb(Zr,Ti)O3 PZT (Pb,La)(Zr,Ti)O3 PLZT PbMg1/3Nb2/3O3 PMN BiFeO3 (Na,K)NbO3 Pyroelectricity and ferroelectricity Pyroelectric or polar materials exhibit an electrical dipole even in the absence of an external electric field. The polarization associated to this electrical dipoles is called spontaneous polarization, Ps (C/m2). The variation of Ps with temperature determines a variation of the surface charge density and originates a pyroelectric current. i dPS dPS dT dt dT dt Ferroelectric crystals are polar crystals in which there are at least two equilibrium orientations of the spontaneous polarization vector in the absence of an external electric field, and in which the spontaneous polarization vector may be switched between those orientations by an electric field. “Fingerprints” of ferroelectric behaviour are: - very high dielectric constant (r>100, often >1000); - sharp peak or anomaly of r around a critical temperature TC; - permittivity obeys the Curie-Weiss law above TC; - hysteresis loop for polarization; -Ps +Ps Not all polar crystals are ferroelectrics, examples are tourmaline and hexagonal CdS. Quartz is only piezoelectric; polarization is induced by the electric field. Antiparallel alignment of elementary dipoles can lead to antiferroelectricity. The paraelectric to ferroelectric phase transition In some perovskites containing Ti or Nb on the B site (BaTiO3, PbTiO3, KNbO3), a phase transition from a paraelectric cubic structure to a lower symmetry phase (tetragonal) with appearance of spontaneous polarization occurs at a critical temperature TC (Curie temperature). Ba Δz Centrosymmetric T<TC, Polar, noncentrosymmetric Spontaneous strain: (cT-aT)/aC cT/ac - 1 Compound TC (°C) PS (μC/cm2) Qc-t (J/mol) cT/aT-1 Δz(Ti) (pm) BaTiO3 125 26 197 1% 120 PbZr0.5Ti0.5O3 (PZT) 380 40-50 - 2.5% - PbTiO3 495 81 4815 6.5% 300 KNbO3 435 30 796 - - TC = 2x104 (Δz)2 The paraelectric to ferroelectric phase transition r' C T T0 1/’r For T>TC: Curie-Weiss law 6 orientations Polarization and order of transition Continuous decrease of Ps: 2° order transition Polarization: order parameter of transition Discontinuity of Ps at Tc: 1° order transition Ferroelectric hysteresis loop and polarization switching PS: saturation (spontaneous) polarization PR: remanent polarization EC: coercive field The slope of the initial polarization curve gives the dielectric constant Ideally +PR = -PR and +EC = -EC -Pr The paraelectric to ferroelectric phase transition The Landau-Ginsburg-Devonshire thermodynamic theory strain electric field 3 Free energy of a crystal subjected to external stresses and electric field. dG SdT xi dXi E dP i 1 stress polarization For centrosymmetric crystals above TC, the function G can be expanded in even powers of polarization. As the polar phases can be regarded as slightly distorted variants of the non polar cubic phase, the same thermodynamic function can be used for all ferroelectric phases (BT, PZT, NaNbO3). For a tetragonal crystal (P1 = P2 = 0; P3 >0) : G 1 P32 11 P34 111 P36 1 1 S12 X 12 X 22 X 32 S12 X 1 X 2 X 2 X 3 X 3 X 1 S 44 X 42 X 52 X 62 2 2 Q11 X 3 P32 Q12 X 1P32 X 2 P32 Q44 X 4 P3 X 5 P3 G 1P32 11P34 111P36 Free energy for zero stress conditions (P = PS) The relevant physical properties (Ps, P, x, ε, etc.) can be determined by minimizing G. The paraelectric to ferroelectric phase transition First order transition (TC > T0) Second order transition (TC = T0) T0 TC T1 T2 In BaTiO3 : T0 = TC-12 T0 Phase transitions in barium titanate Lattice parameters (001)C TC Polarization orientation (110)C C C T (111)C O T R O R TC TC Dielectric constant O/T O/T R/O R/O Spontaneous polarization Phase transitions in ferroelectric perovskites CUBIC NO POLARIZATION Polymorphic phase transition (PPT) in ferroelectrics are determined by: - temperature change; - external electric field; - external stress; The paraelectric to ferroelectric phase transition 1st order transition TC > T0 T > Tm C T T0 ' r Non-linear, hysteretic 2nd order transition TC = T0 Relaxor ferroelectric T(max, ) TC T > Tm r C' T Tm 2 Non-linear, non-hysteretic Ferroelectric domains Non poled FE crystals spontaneously split in domains. A domain is a region with a uniform orientation of polarization. Domains are separated by domain walls. Ferroelectric domains form to minimize the electrostatic energy and the elastic energy associated with mechanical constraints to which the ferroelectric material is subjected as it is cooled through the Curie temperature. Domains with perpendicular orientation of polarization (90° walls) minimize the elastic energy and reduce the depolarizing field (Ed) associated to the surface charges. Formation of 90° domain walls is determined by mechanical stresses. These domain walls differ for both the orientation of polarization (ferroelectric domains) and the orientation of spontaneous strain (ferroelastic domains) Domains with oppositely oriented polarization (180° walls) minimize the depolarizing field (Ed) associated to the surface charges and are purely ferroelectric domains. FE domains in tetragonal BaTiO3 In tetragonal BaTiO3 ceramics formation of complex domain structures with both 180° and 90° walls is observed due to the distribution of stresses and electrostatic boundary conditions to which each grain is subjected. Ferroelectric domains 180° and 90° domain walls 1-10nm c/a = 1.01 <90° dw 10 mJ/m2 Domain walls can easily move under the influence of mechanical stresses (90° walls) and electric field (90° and 180° walls) unless pinned by electrically charged defects. Defects such as oxygen vacancies, trapped electrons and (acceptor ion-oxygen vacancy) pairs can have a strong effect on domain movement. Ferroelectric domains Structure of 90° ferroelastic domain walls in PbTiO3 W = (1.0 ±0.3) nm (001) (101)C <90° c (100) c/a = 1.06 (101) P c P P a Ferroelectric domains Domain wall configurations The number of possible orientations of Ps as well as the number of domain wall configurations increase with decreasing the crystal symmetry. 90 and 180° domain walls 60, 90, 120 and 180° domain walls 71, 109 and 180° domain walls CUBIC NO POLARIZATION Ferroelectric domains The “no bound space charges” principle ( div P = 4Q = 0 in the bulk ) rules the formation of domain structures. 180° domain walls FE domains in single crystal BaTiO3. Combinations of 90° and 180° domain walls FE domains in BaTiO3 ceramics 180° 90° “harring bone” domain structure 90° domain walls 180° domain walls FE domains in BaTiO3 ceramics Fine grained ceramics (0.5-few m) show a simpler domain structure with 90° domain walls. The domains disappear above TC P Heat-to-tail arrangement of domain walls Influence of grain size on the dielectric constant of ferroelectric BaTiO3 ceramics g g d g Model of a cubic grain of size g with 90° domain walls Equilibrium energy density Single 90° dws Complex domains domain 2D arrang. 3D arrangement 0.3-0.5 μm 5 μm Domain-wall contribution to the properties of ferroelectric materials Movement of domain walls (vibration, bending, jump) at weak to moderate fields (subswitching fields) is one of the most important so-called extrinsic (nonlattice) contributions to the dielectric, elastic and piezoelectric properties of ferroelectric materials and may be comparable to the intrinsic effect of the lattice. • Movement of all types of DWs affect polarization and permittivity • Movement of non-180° DWs affect polarization and piezoelectric properties (strain) The dielectric constant of BaTiO3 ceramics decreases with decreasing grain size down to a grain size of about 1 μm. This is ascribed to the increasing density of 90° DWs with decreasing grain size. Similar behaviour observed in PZT ceramics. 1 ' ' ' ' 2 g: grain size r r ,lattice r ,dw r ,lattice Ag d k 90 g 1/ 2 Thickness of domain walls as a function of grain size σ90: domain wall energy FE domains walls as interfaces: conducting domain walls in La:BiFeO3 BiFeO3 thin film with 109° stripe domains PFM amplitude PFM phase C-AFM current 3D current plot Origin: domain wall doping by oxygen vacancies Oxygen vacancies segregate at domain walls (strain gradient, formation of dipoles) and determine a localized increase of the electron concentration. 1 OO VO 2e' O2 2 FE domain walls as interfaces: free-electron gas at charged domain walls in insulating BaTiO3 25 µm tail-to-tail dw head-to-head dw charged dws Charge compensation of polarization charge by free carriers forming a q2DEG at the dw Influence of grain size on the dielectric constant of ferroelectric BaTiO3 ceramics Arlt et al., HPS Frey & Payne, IP Randall et al., CSM Randall et al., HPS Takeuchi et al., SPS Zhao et al., SPS Buscaglia et al., SPS Deng at al., SPS Zhu et al., SPS Wang, 2SS Relative dielectric constant 6000 5000 4000 3000 2000 1000 0 10 100 1000 10000 Grain size (nm) Dilution effect of the non ferroelectric grain boundaries (“dead” layer) Domain size and mobility effect Poling of ferroelectric ceramics If the direction of the spontaneous polarization through the ceramic is random or distributed in such a way as to lead to zero net polarization, the pyroelectric and piezoelectric effects of individual domains will cancel and such material is neither pyroelectric nor piezoelectric. Polycrystalline ferroelectric materials may be brought into a polar state by applying a strong electric field (10–100 kV/cm), usually at elevated temperatures. This process, called poling, cannot orient grains, but can reorient domains within individual grains in the direction of the field. A poled polycrystalline ferroelectric exhibits pyroelectric and piezoelectric properties, even if many domain walls are still present. Poling is only possible in FE ceramics. Ceramics of purely piezoelectric compounds do not exhibit ferroelectric properties (examples: quartz). Before poling, PR = 0 Due to the random orientation of the crystallites, the maximum polarization attainable in a ceramic (PR) is always smaller than in a single crystal and dependent on the number of available domain states: PR = 0.83 PS in tetragonal BT PR = 0.87 PS in rhombohedral BT PR = 0.91 PS in orthorhombic BT In practice PR is much smaller (less than 0.5PS in tetragonal BT) because switching of 90° domain walls is hindered by the large mechanical stress exerted on each grain by the adjacent grains. Only displacement of the 90° domain walls is observed. After poling, PR 0 Ferroelectric hysteresis loop and polarization switching PS: saturation (spontaneous) polarization PR: remanent polarization EC: coercive field The slope of the initial polarization curve gives the dielectric constant Ideally +PR = -PR and +EC = -EC FE hysteresis loop in BaTiO3 -Pr Variation of the hysteresis loop of BaTiO3 with temperature PR = 25 μC/cm2 PR = 8 μC/cm2 Ferroelectric (polarization) fatigue The ferroelectric fatigue is defined as the loss of the switchable remanent polarization in a ferroelectric material as a function of the number of bipolar switching cycles. It is an irreversible phenomenon of primary importance in the development of FERAMs. Fatigue mechanisms: (i) formation of a surface layer; (ii) pinning of domain walls by defects segregated in the wall region; (iii) clamping of polarization reversal by volume defects; (iv) suppression of nucleation of oppositely oriented domains at the surface; (v) damage of electrode/film interface. Oxygen vacancies have an important role in the fatigue process of ferroelectric thin films as they can segregate at electrode/ceramic interface and/or act as pinning centers for the domain walls Absence of significant polarization fatigue with electric field cycling in SrBi2Ta2O9 films with metal electrodes and PZT films with conducting oxide electrodes (IrO2, SrRuO3). Ferroelectric memories (FERAMs) Non-volatile memories, no need for refresh as opposite to DRAMs Samsung 32 Mb ferroelectric random access memories Ferroelectric material Ir/IrO2 electrodes 1 & 2 MBits Ferroelectric nanocapacitor Pb(Zr0.4Ti0.6)O3 -PS -E +PS +E 4 MBits Strain-field loops in ferroelectrics In addition to the polarization–electric field hysteresis loop, polarization switching by an electric field in ferroelectric materials leads to strain–electric field hysteresis (butterfly loops). E P E P P (A) E P P E Ideal ferroelectric with only 180° domain walls (pure piezoelectric response - intrinsic) ABC: elongation (piezoelectric effect S=dE)) CD: strain changes from positive to negative DE: switching EF: elongation FG: strain changes from negative to positive GH: switching Real ferroelectric (PZT) Intrinsic (lattice) + extrinsic (dws) contributions Multidomain (90 + 180° dws) structure. Contribution (non-linear and hysteretic) to strain from movement and switching of non-180° domain walls in addition to pure piezoelectric response. Can be comparable or even greater than the pure piezoelectric response. Pyroelectricity and ferroelectricity Pyroelectric coefficient P pi S T dP/dT Pyroelectric current i T (°C) Pyroelectric coefficient and total released charge in a PZT ceramic Hysteresis loop Spontaneous polarization as deduced from pyroelectric data and from hysteresis loops dPS dPS dT dt dT dt Electrocaloric effect If polarization changes rapidly (under adiabatic conditions) the entropy remains unchanged and temperature changes by ΔT. The effect is maximum slightly above TC, when an electric field can induce a large polarization which goes to zero when the field is removed. T 2 T P 2c Giant Electrocaloric Effect in ThinFilm PbZr0.95Ti0.05O3 (350 nm) c: specific heat ρ: density T: temperature P: polarization β: coefficient from LGD theory Electrocaloric effect in a PLZT film (450 nm) Tc = 115°C TC = 220°C T = -12°C at 480 V/cm (25 V) Nearly constant ECE at 20-120°C Antiferroelectrics In FEs, the off-center displacement occurs in the same direction in all unit cells and results in a macroscopic polarization. In contrast, in same compounds such as PbZrO3 and NaNbO3, the unit cell has a spontaneous electrical dipole but with opposite orientation in adjacent cells, giving a net zero polarization. Like FEs, the AFE compound show a sharp permittivity peak corresponding to transition from a cubic paraelectric phase. The transition temperature is again denoted as Curie temperature. Cubic cell Orthorhombic cell Curie-Weiss behaviour Antipolar arrangement in the a-b plane of orthorhombic PbZrO3. The arrows denote the Pb ions displacement. TC Dielectric constant of ceramic PbZrO3 Antiferroelectrics Double hysteresis loop of PLZT Double hysteresis loops of PbZrO3 at different temperatures TC = 230°C Stability of different FE and AFE phases in PbZrO3 Engineering the phase transitions in ferroelectrics – pressure Phase diagram of BaTiO3 First principles calculation with quantum fluctuations Experimental C T O R Extrapolated from low-P measurements Engineering the phase transitions in ferroelectrics – strain effects in thin films Room-temperature ferroelectricity in strained SrTiO3 Non-strained crystal Incipient ferroelectric Thermodynamic prediction (LGD) Deviation from CW law: quantum fluctuations (100) SrTiO3 film with biaxial in-plane strain r' C T T0 Strained epitaxial film <0: compressive P1=P2=0; P3>0 >0: tensile P1=P2>0; P3=0 LSAT: (LaAlO3)0.29 (SrAl0.5Ta0.5O3)0.71 Engineering the phase transitions in ferroelectrics – strain effects in thin films Enhancement of Ferroelectricity in Strained BaTiO3 Thin Films Thermodynamic prediction (LGD) (001) BaTiO3 film with biaxial in-plane strain <0: compressive P1=P2=0; P3>0 >0: tensile Engineering the phase transitions in ferroelectrics – chemical composition BaTiO3 Sr Zr Ca Ba2+ Ti4+ O2- T/C Dopant Site Charge compensation Ca2+, Sr2+, Pb2+ Ba - Zr4+, Sn4+ Ti - Na+, K+ Ba Oxygen vac. La3+, Nd3+, Sb3+ Ba Cation vac. / e’ Mg2+, Ca2+, Al3+, Fe3+, Yb3+, Co3+, Mn3+, Cr3+ Ti Oxygen vac. Y3+, Dy3+, Ho3+, Er3+ Ba & Ti Depends on incorp. site Nb5+, Sb5+, W5+ Ti Cation vac. T/O O/R Possible phase superposition in solid solutions Engineering the phase transitions in ferroelectrics – chemical composition Ca as amphoteric dopant Incorporation at the Ba site Incorporation at the Ti site with oxygen vacancy compensation CaO TiO2 CaBa TiTi 3OO CaO BaO BaBa CaTi'' VO 2OO Engineering the phase transitions in ferroelectrics – chemical composition Ferroelectric to relaxor crossover in BaZrxTi1-xO3 BaTiO3 FE Ferroelectric Long-range order 1st order transition Macroscopic domains: size >100nm Diffuse FE transition Decrease of correlation length Broadened transition Correlation length of Ti off-centre displacement BaZrO3 non FE Relaxor Short-range order Polar nanoregions: size: 2-10 nm Frequency dependent properties Engineering the phase transitions in ferroelectrics – chemical composition Ferroelectric to relaxor crossover in BaZrxTi1-xO3 Engineering the phase transitions in ferroelectrics – chemical composition Variation of transition temperatures with composition in Ba1-xSrxTiO3 Sr1-xBaxTiO3 Sr1-xBaxTiO3 TC TOT SrTiO3 BaTiO3 SrTiO3 is a quantum paraelectric or incipient ferroelectric without a ferro/para transition. Deviation from Curie-Weiss law Tunability of ferroelectric ceramics Ferroelectric and related materials (SrxBa1-xTiO3) have strongly non linear dielectric properties and their permittivity decreases with increasing dc electric field. To avoid hysteretic behaviour they are usually used in the paraelectric region. However their application in tunable MW devices (varactors) is limited by the high losses. Tunability r' (0) r' ( E ) nr r' (0) Multilayer ceramic capacitors Multilayer ceramic capacitors Ceramic MLCC: n ceramic layers of thickness d separated by metal (Ni, Ag-Pd) electrodes. Capacitance per unit volume: n r 2 CV K d Current market trends: •increase capacitance (increase n and decrease d) •miniaturization (reduce d and size) d n Multilayer ceramic capacitors Some data Main dielectric material: BaTiO3. Yearly production: 11000 tons 2x1012 MLCCs (2011); Dielectric properties are modified by adding dopants (Zr, Ca, Mg, Nb, Y, Ho, Dy, etc.); State of the art capacitors: dielectric layer thickness of 0.5 micron (Murata, Japan); Production technology: tape casting; Metal electrodes: - Noble metals: Ag-Pd, sintering in air with addition of glass to reduce temperature to 1100°C (Ag-30Pd); - Ni (base metal technology, Philips, 1990s): sintering in N2-H2 atmosphere. Addition of “magic” dopants (Y, Dy, Ho) to reduce d=0.5 µm formation of oxygen vacancies and improve lifetime. Applications: consumer electronics (mobile phones, smart phones, PCs, laptops, TVs, etc.), automotive (cars, hybrid cars, electric vehicles). State-of-the-art MLCC: d = 0.5 μm gs ≈100 nm Multilayer ceramic capacitors Specifications Class 1: εr = 5-300, tanδ <<0.01, TCε: 0 to 8000 ppm Class 1: εr = 1000-20000, tanδ: 0.01-0.03, moderate to high TCε X7R X7R: εr = 2000-4000, ±15% from -55 to 125°C Z5U: εr = 5000-15000, +22/-56% from 10 to 85°C Z5U Multilayer ceramic capacitors MLCCs fabrication process (multilayer cofire technology) Multilayer ceramic capacitors Ceramic d = 10 m Metal electrode Dielectric ceramic layer at least 5-7 grains Metal electrode Multilayer ceramic capacitors Miniaturization d=0.5 µm State-of-the-art MLCC: d = 0.5 μm gs ≈100 nm Multilayer ceramic capacitors Miniaturization L x W 0.4 x 0.2 mm 2.0 x 1.2 mm Multilayer ceramic capacitors Pure FE phases can not be used as dielectrics due to the unacceptable variation of permittivity with temperature. Dielectric properties of FE ceramics can be tailored by forming solid solutions and by optimizing microstructure (i) TC and other phase transitions can be shifted and even merged together (ii) The order of the phase transition can be changed: 1° 2° diffuse relaxor (iii) The dielectric constant can be increased by decreasing grain size (limit: 1 μm) A flat temperature dependence of the permittivity can be achieved using ceramics with core-shell grains. The grain consist of a nearly pure ferroelectric BaTiO3 core ( ) with TC = 125°C and of a shell with diffuse ferroelectric of relaxor behaviour and maximum dielectric constant around RT. Most common dopants: Nb2O5, Co3O4, Y2O3, Ho2O3, Dy2O3, MgO Multilayer ceramic capacitors BaTiO3-Nb2O5-Co3O4 Influence of dopant precursor Influence of sintering temperature TS=1320°C Influence of Nb/Co ratio Multilayer ceramic capacitors BaTiO3-Y2O3-MgO TS=1250°C Multilayer ceramic capacitors dc voltage characteristics of commercial MLCCs Low εr non ferroelectric ceramics High εr BaTiO3-based ceramics Emerging applications (e.g. ac/dc inverters) require new dielectric materials with high permittivity and low tunability able to operate in wide temperature range (-50 – 200°C) Multilayer ceramic capacitors Applications in power electronics Bus capacitors act as an energy source to stabilize the dc bus voltage in power electronic circuits such as dc/ac inverters in hybrid electric systems. They possess large capacitance (100–2000 μF), and operate under a stable dc bias with a superimposed ac transient voltage. Functions of inverter: Power the traction motors using energy stored in batteries Regenerative breaking (inverter takes power from motor and store it in batteries) Requirements for dielectric materials: o High and constant permittivity under high dc fields o Low hysteretic losses (especially at high fields) o High energy density