ppt, 6 Mb

advertisement

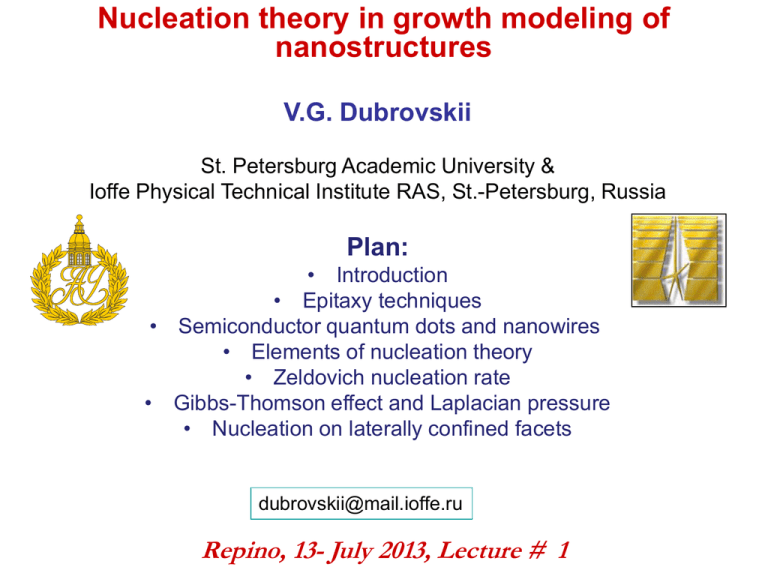

Nucleation theory in growth modeling of nanostructures V.G. Dubrovskii St. Petersburg Academic University & Ioffe Physical Technical Institute RAS, St.-Petersburg, Russia Plan: • Introduction • Epitaxy techniques • Semiconductor quantum dots and nanowires • Elements of nucleation theory • Zeldovich nucleation rate • Gibbs-Thomson effect and Laplacian pressure • Nucleation on laterally confined facets dubrovskii@mail.ioffe.ru Repino, 13- July 2013, Lecture # 1 Modeling of nanostructure formation • • • • • • Growth theory Nucleation Theory of nanostructure formation Quantum dots Nanowires Epitaxial techniques (MBE, MOCVD…) InAs/GaAs(100) QDs Main goals of modeling: Understanding Prediction Optimization New morphology New structure New materials GaAs/GaAs(111)B-Au NWs Size-dependent quantum effects in nanostructures 2 U E 2m SE: DOS: V ( E ) Bulk: 1 dN V dE S (E) 2 m V ( E ) 2 2 1 dN S dE 3/ 2 E E0 DOS of nanostructures: S2 D ( E ) m 2 S1D ( E) nQWR ( E E n ) n 2m ( E Enl ) n,l E Enl S0 D ( E) 2nQD ( E Enlq ) n ,l , q Effect on optical properties: Eopt Eg Ee1 Eh1 Eg E(L) Transformation of QD distribution function into DOS Required properties of NS ensembles: • High uniformity • High density (?) • Controlled composition • Controlled morphology • Controlled crystal structure Morphology of nanostructure ensembles depends on growth process !!! Alfred Cho – the father of MBE Technologies of nanostructure formation: MBE and CVD 1. Molecular beam epitaxy = MBE •Developed in early 70s •Now widely used to produce high-quality layers of different compound semiconductors with very abrupt interfaces and good control of thickness, doping and composition •Materials are deposited in a form of molecular beams on a heated substrate •Molecular beams are originated from thermally evaporated elemental sources (effusion cells) •Growth rates are typically of order of several angstroms per second •MBE system consists of 3 main vacuum chambers: -Growth chamber -Buffer chamber (preparation and storage of samples) -Load lock (to bring samples in and out of the vacuum environment) •Rotating samples (manipulator) •Pressure gauge (ion gauge) •Nitrogen cooler •Cryo-pumps, ion pump, turbo pumps to remove gases, residual pressure is typically less than 10-11 Torr •Substrates holders made from Ta, Mo or pyrolytic boron nitride Scheme of typical MBE system Monitor residual gases, source beams In situ growth control Deposition Example for GaAs: •As (As4 or As2 through a cracker •Ga •Al •In •Be (p-doping) •Si (n-doping) Sample rotation In situ monitoring by RHEED In situ monitoring by RHEED (continued …) Physical nature of RHHED oscillations Modern MBE reactors •GaAs growth •6 x 3 inch substrates •Growth rate 1-3 A/s •10 sources •As cracking •Two parallel loading systems •RHEED •QMA •Cryo-panel •4 standard HEMT processes daily Riber 49 MOCVD •Metal organic chemical vapor deposition (MOCVD) = MOVPE is being used for crystal growth from 1960 and in 1980s was applied for the fabrication of compound semiconductor – based materials and devices •For example, LED structures are grown almost exceptionally by MOCVD •MOCVD systems contain: - the gas handling system to meter and mix reactants - the reactor (vertical or horizontal in design) - the pressure control system -the exhaust facilities •Basic principle is the deposition of the required growth species with precursors at ~ atmospheric pressure of a carrier gas and chemical reaction in the temperature field of a heated substrate •Group III sources are trimethylgallium (TMGa), TMAl, TMIn •Group V species are typically hydride gases such as arsine (AsH3) and phoshpine (PH3), or NH3 for GaN •Very high V/III ratios (50-100) because the incorporation of group V elements Is self-limited (very high partial pressure of group V species) •Growth rate and composition is controlled by partial pressures of the species and by the substrate temperature Chemistry of MOCVD growth process for GaAs H2 Source of a metal-organic compound (liquid or solid state) Radiofrequency generator (~450 kHz) Vapors in H2 Hydrides (gaseous) Example of chemical reaction for the GaAs epitaxy: H2 (CH3)3Ga + AsH3 GaAs + 3CH4 0 600 C Heating up to 600-7000С Chemical reaction Growth of compound semiconductor on a crystal substrate Exhaust of gases Modern MOCVD reactors (1-x)Ga(CH3)3 + xIn(CH3)3 + NH3 -> InxGa1-x N + 3CH4 Reactor Aixtron 2000/HT (2003): GaN growth 6 x 2-inch substrates Productivity > 500 blue LED structures monthly Each wafer contains ~ 10 000 LED chips 0.35*0.35 mm Heterostructres for blue-green and white LEDs Main technological stages: •Wafers Al2O3 •Materials (TMGa, TMAl,TMIn, gases) •Epitaxial growth of LED heterostructure • Processing and production of chips •Packaging •Fabrication of final device Increasing In concentration in InGaN => larger wavelength Direct formation of Stranski-Krastanow QDs 20 nm Island growth (Volmer-Weber) Substrate Layer by layer growth (Frank – van der Merve) Substrate Wetting layer Combined growth (Stranski-Krastanow) Substrate h L WETTING LAYER SUBSTRATE SK growth mode Relaxation of elastic stress in the island – main driving force for 2D-3D transition Direct formation of QDs (continued …) At h=h1c, RHEED pattern changes from strikes to spots InXGa1-XAs/GaAs dislocations 2D-3D Critical thickness, ML 100 2 ML InAs/GaAs 10 Coherent stained islands Dislocations ε0>2% 1 0.0 0.2 0.4 0.6 0.8 InAs mole fraction, x 1.0 Critical thickness h1c for 2D-3D transition VLS growth of “whiskers” by Wagner & Ellis and Givargizov Wagner & Ellis, APL 1964 Пар-жидкость-кристалл или ПЖК (в английской литературе — vapor-liquidsolid — VLS)) — механизм роста одномерных структур, таких как нановискеры в процессе химического осаждения из газовой фазы. High temperature (T ~ 1000-11000 C) CVD experiments of 1960-70s with micrometer diameters Formation of vertical nanowires on activated surfaces by MBE GaAs/GaAs(111)B-Au 1-st stage (MBE chamber): oxide desorption from GaAs substrate and buffer layer growth GaAs wafer Au film 2-st stage (Vacuum or MBEchamber): Au deposition on a GaAs substrate surface GaAs wafer GaAs NW 3-st stage (MBE chamber): formation of Au-Ga alloy droplets; deposition of GaAs – growth of NW GaAs wafer Typical RHEED patterns during the wire growth 200 nm GaAs/Si(100) 200 nm GaAs/GaAs(111)B ZB and WZ phase of III-Vs All III-V NWs, except nitrides, have STABLE ZB cubic phase in BULK FORM In GaAs: Difference in cohesive energies = 16. 6 – 24 meV per pair at zero ambient pressure. T.Akiyama et al, Jpn.J.Appl.Phys, 2006; M.I.McMahon and R.J.Nelmes, PRL, 2005 ABC=ccc=3C=∞ ABA=hhh=2H=(11) Bulk ZB GaAs becomes unstable at pressure ~ 80 GPa !!! Most of ZB III-V nanowires contain WZ phase: A.I.Person et al., Nature Materials 2004, Au-assisted MOVPE of III-V/III-V J.C.Harmand et al., APL 2005, Au-assisted MBE of GaAs/GaAs I.P.Soshnikov et al., Phys. Sol. State 2006, Au-assisted MBE of GaAs/GaAs P.Mohan et al., Nanotechnology 2005, selective area catalyst free growth of III-Vs C.Chang-Hasnain group, Au-assisted MOCVD of III-V/Si AND MANY OTHERS! Hexagonal WZ phase in III-V NWs !!! LPN CNRS: APL 2005 GaAs NWs on GaAs InAs NWs on InAs [1 1 0 0] zone axis C. Chang-Hasnain, group: 0002 0000 APL 2007 1120 InP NWs on Si TEM image FFT of TEM image ZB-WZ transition in GaAs NWs (Ioffe & LPN) Au-assisted MBE of GaAs on the GaAs(111)B substrate ZB Switching from WZ to ZB at the end of growth WZ I.P.Soshnikov et al, Phys. Sol. State 2005 Switching from ZB to WZ at the beginning of growth ZB phase systematically appears at low supersaturation ! F.Glas et al., Phys. Rev. Lett 2007 Nucleation Consider 2D island of ML height h, area A=c1r2 and perimeter P=c2r, r = “radius” Gibbs free energy of 2D island formation (fixed T, P, N): G i c2 hrg hr 2 c1r 2 i c1 S s k BT ln( 1) F (i) 2 ai i ln( 1) (1a) in kBT units Difference in Surface term chemical potentials (energetically (energetically unfavorable) favorable) 2 c2 a S h(g / k BT ) 2 4c1 i Surface energy constant γ – solid-vapor surface energy per unit area (J/m2) Δμ – difference of chemical potentials (J) Normally, a is a large parameter ~ several tens A=s i h g Gibbs free energy sn=10-3 , a=15 =0.75 (1), 1 (2), 1.5 (3) and 2 (4). Activation barrier for nucleation: ln( 1) Critical number of atoms: ic a ln ( 1) 2 Half-width near maximum: ln ( 1) F (ic ) 2a 3 20 Free energy of island formation, F F F (ic ) a 1 15 10 2 F 3 5 ic 0 0 10 20 4 30 40 50 60 Number of atoms, i F and ic decrease as supersaturation increases !!! A story about Zeldovich and nucleation theory ФИЗИЧЕСКИЕ ОСНОВЫ ТЕОРИИ ФАЗОВЫХ ПРЕВРАЩЕНИЙ ВЕЩЕСТВА (КУНИ Ф.М. , 1996), ФИЗИКА Сформулированы цели современной теории фазовых превращений, введены понятия о стабильных и нестабильных фазах вещества, образовании зародышей стабильной фазы в недрах метастабильной, вероятностно-статистическое представление о потоке зародышей как о ведущей кинетической характеристике фазового превращения. Описана временная зависимость фазового превращения (уравнение Зельдовича ???). Я.Б. Зельдович Nucleation rate Region 1: Equilibrium size distribution exp(F)>>1 f e (i) n exp[F (i)] I – nucleation rate [1/cm2s] Region 2: Fluctuations [ flux I] F dic/dt=0 Region 3: Growth f(i,t) – island size distribution [1/cm2] I III II Kinetic equation for size distribution in region II: i f J t i Boundary conditions: f J W (i) f e i f e f s / f e 1, i 0 ic-Δic ic ic+Δic i 2 / F (ic ) f s / f e 0, i Nucleation rate (continued…) Stationary solution at J=const with the 2nd boundary condition: di f s (i) J exp[F (i)] exp[F (i)] W (i) i J=0 equilibrium J=const steady state To meet the 1st boundary condition, I should equal: di J n exp[F (i )] 0 W (i ) i+1 1 i Laplace method i-1 / F (ic ) / J n W (ic ) exp( F ) 2 General Zeldovich formula a J ( 1) ln ( 1) exp ln( 1 ) s D 1 1/ 2 for 2D islands Gibbs-Thomson effect and Laplacian pressure PV Consider liquid (L) spherical drop of radius R in equilibrium with vapor (V) Find PL-PV, PL and PV PL R Solution: γ 1) System at fixed T, V and μ => maximum of PLVL PVVV gA d 0 at constant volume dV dVL dVV PL PV gdA/ dV For a sphere with 2g PL PV R A 4R 2 V 4R 3 / 3 Laplacian surface pressure 2 For a cylindrical isotropic solid with A 2RL V R L yields PS PV g R GT effect and Laplaciam pressure (continued …) 2) At finite R, equilibrium state is defined by L ( PL ) V ( PV ) (1) At R→∞, equilibrium state is defined by L ( P ) V ( P ) (2) Subtract (1) from (2); take into account that liquid is incompressible and that vapor is ideal V kBT ln P (T ) 2 Lg L ( PL ) L ( P ) L ( PL P ) L ( PL PV ) R V ( PV ) V ( P ) k BT ln(PV / P ) Vapor: Liquid: PV ln P 2g PL P R L ( PL ) L ( P ) 2 L g R 2 L g k BTR 2 L g V ( PV ) V ( P ) R Mononuclear and polynuclear growth I – nucleation rate, v=dr/dt – 2D island growth rate, R – face radius I and v are time-independent during growth (constant supersaturation) Polynuclear growth is generally faster ! VL = vertical growth rate of facet of radius R due to 2D nucleation VL Generally, VL=f(I,v,R) JR v 3 R 2 J , 1 VL h 1/ 3 v 2 J , 1 R Kashchiev interpolation formula: VL h R Dependence on the nucleation barrier: R J 2 1 J / v R 2 2/3 VL mono (1/ )(R2 / s ) exp(G* / kBT ) VL poly (1/ ) exp(G* / 3k BT ) A story about Kolmogorov-MehlJohnson-Avrami model Википедия: A. Kolmogorov Уравнение Джонсона — Мела — Аврами — Колмогорова (англ. Johnson — Mehl — Avrami — Kolmogorov equation, JMAK) описывает процесс фазового перехода при постоянной температуре. Изначально оно было получено для случая кристаллизации расплавов в 1937 году А. Н. Колмогоровым, и независимым образом в 1939 году Р. Ф. Мелом и У. Джонсоном, а также было популяризировано в серии статей М. Аврами в 1939—1941 годах.