Kaptay / Day 3 / 4

advertisement

See J94

Kaptay / Day 3 / 1

Day 3.

Interfacial energies in high temperature systems

George Kaptay

A 4-day short course

1

Kaptay / Day 3 / 2

Modeling algorithm

Interfacial energies

Interfacial forces

Interfacial phenomena

Complex phenomena

2

Kaptay / Day 3 / 3

Types of phases and interfaces to be modeled

W(s)

gas

NaCl(l)

Al(l)

MgO(s)

Si(s)

AlN(s)

TiC(s)

3

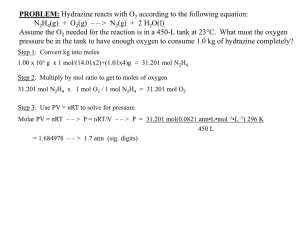

Kaptay / Day 3 / 4

Modeling interfacial energies

A

B

A/ B

G A / B

A/ B

The excess interfacial Gibbs energy:

GA / B G

A

A/ B

G

B

A/ B

G A / B H A / B T S A / B

4

See J48

Kaptay / Day 3 / 5

The excess interfacial enthalpy

for the liquid/gas interface

H lA/ gB

zbA ziA

o

o

U lA A U lA

zbA

For liquid metals (structures surface – see Day 1 / 18):

(11-9)/11 = 0.182

Where the cohesion energy of the liquid metal (classic):

U lAo v H Ao R T

5

See J48

The excess interfacial entropy for the

liquid/gas interface

Kaptay / Day 3 / 6

S sA / g

Vi

R ln

Vb

From the LEED measurements [Somorjai et al]:

S sA / g

u

R ln

u

2

2

b

1/ 2

R ln

b

SlA/ gB S sA / gB 4 1 J / molK

6

See J48

The molar surface area of the liquid/gas interface

Kaptay / Day 3 / 7

4

3 N Av

Vm r

3

fb

N Av

r

fi

2

f Vm N Av

2/3

1/ 3

3 f b

f

4

2/3

1/3

fi

For the {111} plane of the fcc crystal: fi = 0.906.

For fcc crystals fb = 0.740 → f = 1.09.

When an fcc crystal is melted, ΔmV = 1.06, → f = 1.06.

7

See J48

Surface tension of pure liquid metals

Kaptay / Day 3 / 8

lAo / g

0,182 v H Ao (5,5 1) T

1,06 V

o 2/3

A

N 1Av/ 3

Experimental points

Calculated values

8

Kaptay / Day 3 / 9

Surface tension of liquid metals / new age (1)

HlA/ gB A H

H H

o

c,i

o

c,i ,m

H

(11-9)/11 = 0.182

o

c ,i

C (T T )

o

p ,i

o

c,i ,m

H

o

m,i

C (T

o

p,i

o

cr,i

o

c ,i ,Tcr ,i

0

T )

o

m,i

To correlate the calculated values:

H

o

c ,i , m

q1 R T

o

m,i

q R T

2

o 2

m,i 9

Kaptay / Day 3 / 10

From vaporization enthalpy

160000

Rb

Na

K

120000

Cs

Hg

80000

-H

o

c,i,m

J/mol

q1 = 25.4 ± 1.2, q2 = 0.

Li

40000

From critical points

0

0

1000

2000

. o

RT

H

o

c ,i , m

m ,i

q1 R T

o

m,i

3000

4000

J/mol

q R T

2

o 2 10

m,i

Kaptay / Day 3 / 11

Surface tension of liquid metals / new age (2)

3 fb

f

4

2/3

1/ 3

fi

For the {111} plane of the fcc crystal: fi = 0.906.

For fcc crystals fb = 0.740 → f = 1.09.

For melted fcc crystals fb,fcc = 0.74/(1.12) = 0.66 → f =1.01

For melted bcc crystals fb,bcc = 0.68/(1.096) = 0.62 → f=0.97

For melted hcp crystals fb,hcp = 0.74/(1.086) = 0.68 → f=1.03

11

Average for melted fcc, bcc and hcp crystals: f = 1.00 ± 0.02

Kaptay / Day 3 / 12

Surface tension of liquid metals / new age (3)

S

S

o

i/ g

o

vib i / g

S

o

vib i / g

ord S

o

i/g

S

o

i/g

5 1J / molK

S 6 2J / molK

o

m i

S

o

vib i / g

H H

o

c,i

ord S

o

i/g

o

c,i ,m

ord S

o

i/g

1 3

C (T T )

o

p ,i

o

m,i

12

Kaptay / Day 3 / 13

Surface tension of liquid metals / new age (4)

o

i,m

(0.182 0.02) H

H

(1 3) T

o

c,i , m

o 2/3

N

(1.00 0.02) Vi , m

o

c ,i , m

q1 R T

o

m,i

o

m,i

1/ 3

Av

q R T

o 2

m,i

2

q1 = 25.4 ± 1.2, q2 = 0.

o

i,m

(38 10)

o

m,i

T

V N

o 2/3

i,m

1/ 3

Av

13

Kaptay / Day 3 / 14

1

4

Ga

2

0.8

2

i,m, exp, J/m

3.5

i,m, exp, J/m

In Sn

3

0.6

Hg

Ge

0.4

Bi

Sb

0.2

Re

0

2.5

0

0.2

0.4

0.6

0.8

2

i,m, calc, J/m

1

1.2

Ir

Fe

W

Co

2

Ni

Ta

V

1.5

Pt

Al

Zr

1

Tl

0.5

Cu

Ag

K Na

Sr

0

Au

Pb

Hf

Ca

Cs

0

0.5

1

1.5

2

2.5

i,m, calc, J/m2

3

q1 = 26.3 and q2 = -2.62.10-4 molK/J

3.5

4

14

Kaptay / Day 3 / 15

T-coefficient of surface tension / new age (5)

o

i

q1 R T q2 R T

1

o 2/3

i,m

fV

o

i

o ,T

i

C T T S

T T N

o 2

m,i

o

m,i

o

i,m

o

i

o,T

i

(0.182 0.026) C

o

m,i

2/3

o

i/g

1/ 3

Av

(T T )

o

p ,i , m

(1 3)

1/ 3

Av

o

m,i

o

m,i

V N

o 2/3

i,m

o

p,i

2 o o

i i , m

3

15

T

Kaptay / Day 3 / 16

0.25

2

T i,m, exp, mJ/Km

T i,m, exp, mJ/Km

2

0.5

0.4

Hg

0.2

0.15

Sn

In

Ni

Ge

Bi

0.1

0.05

Ga

0.3

Co

Sb

0

0

0.03

T

0.06

0.09

2

,

calc,

mJ/Km

i,m

0.12

Cu

Au

0.2

0.15

Ag

Pb

K

0.1

Na

Al

Cs

Tl

Ca

Sr

0

0

0.1

0.2

0.3

i,m, calc, mJ/Km2

T

0.4

0.5

16

Kaptay / Day 3 / 17

The classic model for surface tension was

improved by changing 2 things at the same time:

i. the cohesion energy is made T-dependent through heat

capacity (known for 130 years)

ii. a new, ordering term is taken into account in the excess

surface entropy (known for 30 years)

General lesson: Models exist on almost everything.

Majority of them can be improved. If you change only one

thing in the model, usually you spoil it. You must be brave

enough to change at least two (sometimes three), different

17

things in the model to get it work again – in a better way.

See P75

Surface structure of MX type molten salts

Kaptay / Day 3 / 18

-

+

-

-

+

+

-

+

Vapour

-

+

-

o

VMX

2 (rM rX ) 3 N Av

MX

10 9

0.1

10

+

+

-

Bulk liquid of

MX associates

-

+

o

MX

2 (rM rX ) 2 N Av

f MX 21 / 3 1.26

SlMX / gB SlM / gB 3 2 J / molK

18

Kaptay / Day 3 / 19

Surface tension of MX molten salts

o

MX

/g

o

0,10 v H MX

(3,8 2) T

1,26 V

o

MX

2/3

N 1Av/ 3

Experimental points

Calculated values

19

Kaptay / Day 3 / 20

Surface tension of molten monoxides (MO)

MO

FeO

MgO

CaO

SrO

BaO

o

MX / g

0,10 v H

o

MX

1,26 V

o

MX

vH

T

K

kJ/mol

1.650

2523

1823

1823

1823

413.2

574.9

578.3

477

336.4

(3,8 2) T

2/3

N 1Av/ 3

Vl

MO/g,

cm3/ mJ/m2

mol

model

15.8

532 70

16.5 695 100

21.1

623 90

27.8

425 60

34.1

239 30

MO/g, J/m2

measured

550 50

700 100

650 100

20

250 50

Kaptay / Day 3 / 21

Surface energy of solid metals

o

sA / g ,Tm

1.15

o

lA/ g ,Tm

21

Kaptay / Day 3 / 22

Surface energy of solid metallic mono-carbides

o

sMC / g

M

Ti

Zr

Hf

V

Nb

Ta

W

o

sM / g

VoM

cm3/mol

10,55

14,01

13,41

8,34

10,84

10,87

9,53

V

V

o

M

o

MC

VoMC

cm3/mol

12,15

15,34

15,03

11,49

13,42

13,40

12,42

2/3

s H 717 f H

o

M

2 s H

sHoM

fHoMC

kJ/mol

469,9

608,8

619,2

514,2

725,9

782

849,4

kJ/mol

-184,1

-202,5

-208,4

-101,9

-140,6

-144,0

-40

o

M

sM/g

J/m2

1,88

2,02

2,12

2,15

2,51

2,87

3,11

o

MC

MC/g

J/m2

2,50

2,39

2,45

2,26

2,38

2,45

2,47

22

Kaptay / Day 3 / 23

Surface energy of solid ionic mono-oxides

o

sMO / g

MX

(0,08 0,01) s H

1,26 V

sH,

o

sMO

o

MO

2/3

(3,8 2) T

N

1/ 3

Av

MO/g, J/m2

MO/g, J/m2

T, K

kJ/mol

Vs,

cm3/mol

NaCl

231

27,0

0

0,20 0,02

0,212

MgO

656

11,0

0

1,00 0,12

1,04

CaO

677

16,6

298

0,78 0,10

0,82

SrO

578

21,9

0

0,56 0,07

-

BaO

425

26,7

1373

0,30 0,05

0,29

FeO

523

12,3

0

0,74 0,09

0,732

23

exp

See J67

Excess interfacial enthalpy of sA/lA interface

Kaptay / Day 3 / 24

The Kelvin equation for the critical radius of nucleation:

2 sA / lA m H Ao

rcr

V Ao

The molar volume can be modeled as:

T

1

Tm , A

4

3 N Av

V rA

3

fb

o

A

m H Ao

3.224 rA

sA / lA

1/ 3

o 2/3

fb

rcr

VA

N 1Av/ 3

T

1

T

m

,

A

At T 0 K, the solid nucleus will be stable from an atom, i.e. rcr rA:

H sA / lA

f b1/ 3

m H Ao

3.224

24

Kaptay / Day 3 / 25

Excess interfacial entropy of sA/lA interface

From side of the solid there is not too much change in freedom:

S sAsA/ lB 0

Liquid atoms will loose part of their freedom at the s/l interface.

The entropy of melting:

m S m S vol m S conf m S str

The excess interfacial entropy:

sAo / lA

lB

S sA

/ lB 0,5 ( m S B,vol m S B,conf )

f b1 / 3

T

o

mH A

m S A,vol m S A,conf

3,224

2 1,06

0,986 V

o 2/3

lA

N

1/ 3

Av

25

Kaptay / Day 3 / 26

Interfacial energy sA/lA

exp , mJ/m

2

sAo / lA

f b1 / 3

T

o

mH A

m S A,vol m S A,conf

3,224

2 1,06

0,986 V

o 2/3

lA

N 1Av/ 3

400

300

200

100

0

0

100

200

300

theor, mJ/m

2

400

26

Kaptay / Day 3 / 27

Summary of interfacial energies of

pure metals (example: Fe)

Tm

3

sg

g , J/m

2

2,5

2

lg

1,5

1

sl

0,5

0

0

500

1000 1500

T, K

2000

2500

27

Kaptay / Day 3 / 28

Interfacial energy sA/lB

There is an extra excess enthalpy term, connected with the interaction of

A and B atoms across the interface:

H sA / lB H sAsA/ lB H sAlB / lB (H sAiA / lB H Ab ) (H sAiB / lB H Bb )

( ziA U AA ziAB U AB zbA U AA ) ( ziB U BB ziBA U AB zbB U BB )

1

2 ( zbA ziA ) U AB (U AA U BB )

2

From the theory of regular solutions:

A B

1

zbA U AB (U AA U BB )

2

Finally, the new excess enthalpy term:

H sA / lB 2 A 28AB

Kaptay / Day 3 / 29

f b1, /A3

sA / lB

3,224

Interfacial energy sA/lB

m H 2 lAlB

o

A

T

m S B ,vol m S B ,conf

2 1,06

V V

o 1/ 3

sA

o 1/ 3

lB

2/3

N Av

Zn/Sn (473 K), Ag/Pb (608 K), Cu/Pb (1193 és 1093 K), Fe/Cu (1373

K), Nb/Cu (1773 K), W/Cu (1773 K), Mo/Sn (1873 K), W/Sn (2273

K),

29

Fe/Pb (1373 and 1193 K) and Fe/Ag (1373 K)

Kaptay / Day 3 / 30

Interfacial energy between two immiscible liquids

lA / lB

2 lAlB S lAlB T T

1

lA / g lB / g

Tc

1.26

lA/lB, mJ/m

2

160

120

80

Al-Bi

40

Ga-Pb

0

0

300

600

T

900

1200

1500

Ga-Pb: D.Chatain, L.Martin-Garin, N.Eustathopoulos: J. chim.phys., 79 (1982) 569

30

Al-Bi: I.Kaban, W.Hoyer, M.Merkwitz: Z.Metallkunde, 94 (2003) p.831

Kaptay / Day 3 / 31

Covalent ceramic / liquid metal interface

The London dispersion forces connect the atoms across the interface:

U a a

WsAC / lB

I B Ii

3

A B i

2

I B Ii

A

2r6

3

1

4 sAC lB

B

Cu

Ga

Sn

Pb

Bi

B C

I B IC

B A I B I A

xA

xC

6

6

I

I

I

I

(

r

r

)

(

r

r

)

B

A

B

C

B

A

B

C

WSi/B

model

mJ/m2

22,6

16,4

9,9

5,6

5,2

WN/B

model

mJ/m2

60,5

38,7

20,3

10,0

8,8

WSiN4/B

model

mJ/m2

83,1

55,0

30,2

15,6

14,0

WSiN4/B

exp

mJ/m2

81,4

56,8

36,5

24,8

23,2

31

See J66

Ionic ceramic / liquid metal interface (1)

Kaptay / Day 3 / 32

The ion A induced dipole (in atom B) interaction with each other:

U AB

z A2 e 2 B

4 π ε o (rA rB ) 4

The adhesion energy:

WA / B

z A2 e 2

2 B, g N Av

3 6 B 4 π εo (rA rB ) 4

The corrected adhesion for dipole induced dipole interaction::

W AC / B

z A2 e 2

2 B , g N Av

3 6 B 4 π ε o (rA rB ) 4

4 B , g AC

1

6

6 (rA rB ) 32

Kaptay / Day 3 / 33

Ionic ceramic / liquid metal interface (2)

The corrected adhesion energy for ion the ionic moment of ion C:

W AC / B

2

z

B

,

g

A

1,54 105 k2, AC

B (rA rB ) 4

2 B , g AC

1

6

3 (rA rB )

33

Points from for the liquid Cu / MgO, ZrO2, Al2O3, SiO2 systems

Kaptay / Day 3 / 34

Wettability of solid Fe by molten chlorides

W AC / B

2

zA

B, g

5

2

1,54 10 k , AC

B (rA rB ) 4

2 B , g AC

1

6

3 (rA rB )

WAC/B

mJ/m2

AC/g

B/AC/g

mJ/m2

fok

0,39

66,4

138

121

3,48

0,44

85,0

147

115

0,138

2,62

0,48

101,9

169

114

NaCl/Fe

0,098

1,85

0,52

118,8

114

88

KCl/Fe

0,133

1,36

0,55

133,2

99

70

AC/B

rC

nm

IC/IA

MgCl2/Fe

0,074

4,89

CaCl2/Fe

0,104

BaCl2/Fe

k

Calculated data are confirmed experimentally by Vetiukov et al.

34

Kaptay / Day 3 / 35

Interfacial energy in liquid metal / molten salt systems

W AC / B

2

zA

B, g

5

2

1,54 10 k , AC

B (rA rB ) 4

2 B , g AC

1

6

3 (rA rB )

T.Utigard, J.M.Toguri, T.Nakamura, Metall.Trans. B., 17B (1986) 339

NaF/Bi (1373 K), NaCl/Bi (1373 K), NaF/Pb (1273 K), NaCl/Pb (117335K),

NaF/Ag (1273 K), NaCl/Ag (1273 K), NaF/Cu (1373 K) and NaCl/Cu (1373 K)

Kaptay / Day 3 / 36

Concentration dependence of (Gibbs, 1878)

The surface excess (by definition):

o

B

B xB * xB

o

B

1

B

n

The Gibbs equation:

d i d i

i 1

di R T d ln ai

i R T ln ai

o

i

+Gibbs-Duhem

(for binaries):

aB

R T B d ln a B

o

A

0

36

Kaptay / Day 3 / 37

Langmuir (1918)

The equilibrium between bulk and surface phases:

A* + B = A + B*

ads G o

K exp

RT

x B * a A

K

(1 x B *) a B

For the infinitely diluted solution of B in A: aA = 1, aB= gB xB

b xB

xB *

1 b xB

b K g

B

37

Kaptay / Day 3 / 38

Belton (1976)

b xB

xB *

1 b xB

B xB * xB

o

B

o

B

1

B

xB

b

B

1

B 1 b xB

aB

R T B d ln a B

o

A

0

o

A

R T

B

Integration at infinitely

diluted solution of B:

dlnaB = dxB/xB.

ln(1 b x B ) x B

38

Kaptay / Day 3 / 39

Gibbs – Langmuir – Belton (1878 – 1976)

At infinitely diluted solution of B: xB << 1 (and if b >>1)

o

A

R T

ads G

Ka exp

RT

o

o

B

ln(1 K a aB )

A* + B = A + B*

Ao Ao Bo Bo

K a exp

R T

[??]

39

Kaptay / Day 3 / 40

Theoretical Concentration dependence of Fe-O/g

(1823K ) 1960 291 ln(1 284 CO )

40

Kaptay / Day 3 / 41

Theoretical concentration dependence of Fe-S/g

(1823K ) 1960191 ln(1 523 CS )

41

Kaptay / Day 3 / 42

Additive extension to ternary Fe-O-S system

FeOS / g 1960 291 ln(1 284 aO ) 191 ln(1 523 aS )

Experimental points

Calculated values

42

Kaptay / Day 3 / 43

Taking into account the competition

between O and S atoms for surface sites

A B C

R T

K a , BaB K a ,C aC

o

A

K a , BaB K a ,C aC

ln1 K a , BaB K a ,C aC

o

o

C

B

Experimental points

Calculated values

43

Kaptay / Day 3 / 44

On the Butler equation (1932)

A B / g A / g B / g

A B / g

o

A/ g

R T

o

A

aA *

aB *

R T

o

ln

B / g o ln

aB

aA

B

Compared to the Gibbs equation:

i. it is easier to teach and to apply, but still

ii. at equal assumptions it provides the same results.

The surface activity coefficient as function of surface

44

composition is to be modelled

Kaptay / Day 3 / 45

Modeling surface excess Gibbs energy

R T ln a A * R T ln x A * G

Ei

A

The model is based on the ratio of broken bonds ():

G AEi (1 ) G AE

For liquid metals: Hoar, Melford, 1957: 0.330.50

Monma, Suto, 1961: = 0.16 -0.20,

Speiser, Poirier, Yeum, 1987 – 1989: = 0.25,

Tanaka, Iida, Hara, Hack, 1994 – 2000: = 0.17,

For molten salts: Tanaka et al.: = 0.06, later -0.1 (!!??)

45

Kaptay / Day 3 / 46

The Butler equation, applied to associated liquids

AaBb

o

a A A b B B f H AaBb

a A b B

Al-Ni

Experimental points: V.N.Eremenko, V.I.Nizhenko, N.I.Levi,

46

B.B.Bogatirenko: Ukr. Him. Zh., 1962, vol.28, No.4, pp.500-505

See J99

Surface phase separation in monotectic alloys (a)

A/ g B / g

Kaptay / Day 3 / 47

A = 1 J/m2, B = 0.5 J/m2, VA = 1 10-5 m3/mol, VB = 2 10-5

m3/mol, = 20 kJ/mol. Then: Tc = 1202.79 K.

At T = 875.86 K, bulk separation at xB = 0.1 and xB = 0.9

1

Fig.1.a: XB = 0.00068

A

B

A, B, J/m

2

0,99

0,98

0,97

solution

0,96

0

0,2

0,4

xB*

0,6

0,8

1

Partial surface tensions as function of surface content

47

See J99

Surface phase separation in monotectic alloys (b)

Kaptay / Day 3 / 48

1

Fig.1.b: XB = 0.00072

0,99

A, B, J/m

2

A

B

0,98

0,97

solution

0,96

0

0,2

0,4

xB*

0,6

0,8

1

48

Partial surface tensions as function of surface content

See J99

Surface phase separation in monotectic alloys (c)

Kaptay / Day 3 / 49

1

Fig.1.c: XB = 0.000755

A, B, J/m

2

0,99

A

B

0,98

0,97

2 solutions

0,96

0

0,2

0,4

xB*

0,6

0,8

1

49

Partial surface tensions as function of surface content

See J99

Surface phase separation in monotectic alloys (d)

Kaptay / Day 3 / 50

1

Fig.1.d: XB = 0.00080

A, B, J/m

2

0,99

solution

A

0,98

0,97

B

0,96

0

0,2

0,4

xB*

0,6

0,8

1

50

Partial surface tensions as function of surface content

See J99

Surface phase separation in monotectic alloys (e)

Kaptay / Day 3 / 51

1

Fig.1.e: XB = 0.00085

A, B, J/m

2

0,99

A

0,98

solution

0,97

B

0,96

0

0,2

0,4

xB*

0,6

0,8

1

51

Partial surface tensions as function of surface content

See J99

Surface phase separation in monotectic alloys (f)

Kaptay / Day 3 / 52

0

logxB*

-1

-2

-3

-4

-6

-5

-4

-3

-2

-1

logxB

Surface composition as function of bulk composition 52

0

See J99

Surface phase separation in monotectic alloys (g)

Kaptay / Day 3 / 53

1.2

, J/m

2

1

0.8

0.6

0.4

0.2

0

-6

-5

-4

-3

-2

-1

0

logxB

Surface tension as function of bulk composition

53

See J99

Surface phase separation in monotectic alloys (h)

Kaptay / Day 3 / 54

1400

1200

1 bulk liquid

*

cr

T

T, K

1000

800

SPT line

Tcr

1 bulk liquid

+ nanolayer

600

2 bulk liquids

400

200

0

-6

Fig.2.c

-5

-4

-3

-2

-1

logxB

A phase diagram with a surface phase separation line54

0

See J99

Surface phase separation in monotectic alloys (i)

Kaptay / Day 3 / 55

T=800 K

d /dT 104, J/m2K

8

6

T=986 K

4

2

T=1200 K

0

-2

-4

-3.5

-3

-2.5

-2

-1.5

-1

logxB

55

T-coefficient of surface tension as function of bulk composition

Kaptay / Day 3 / 56

Two shapes of welding pools

1400

1200

1 bulk liquid

T

T, K

1000

800

SPT line

Tcr

*

cr

1 bulk liquid

+ nanolayer

600

2 bulk liquids

400

200

0

-6

-5

-4

-3

-2

-1

0

logxB

d

0

dT

d

0

dT

56

Thank you for your attention

57