剪力波速量測應用於礫石質砂土液化潛能研究

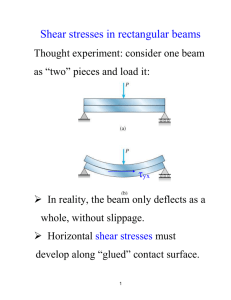

advertisement

U.S.-Taiwan Liquefaction Workshop 國立中興大學 A Study on Liquefaction Evaluation Using Shear Wave Velocity for Gravelly Sand Deposits Ping-Sien Lin , National Chung-Hsing University Fu-Sheng Chen , China Engineering Consultants, Inc. Yin-Yu Jan , China Engineering Consultants, Inc. Chi-Wen Chang , National Chung-Hsing University Wen-Jong Chang , National Chi Nan University 國立中興大學 Outline Introduction Literature Review Testing Program Results and Discussions Conclusions Future Works 國立中興大學 Research Initiation Soil liquefactions occurred in central Taiwan area after Chi-Chi Earthquake (Mw=7.6). Liquefactions of gravelly soil observed in the Wufeng and Nantou Area No proven methods for estimating the CRR of gravelly soil because of the existence of gravels 國立中興大學 Ground settlement caused by sand boiling (Taichung port) 國立中興大學 The Song-Gee Jewellery Store Inclined Severely and the Footing was Suck Research Framework 國立中興大學 In situ testing methods: – Large Hammer Penetration Test (LPT) – In situ shear wave velocity measurement (Vs) Laboratory works: – Large-scale cyclic triaxial tests (15 cm ×30 cm) to determine CRR – Cyclic triaxial tests with Vs measurements Goal of research: Find appropriate techniques for liquefaction potential assessing in gravelly soils 國立中興大學 Liquefaction Literature Review evaluation framework – Simplified procedure proposed by Seed (1997 NCEER Workshop) – CSR=f (M, amax, sv, rd) – CRR from laboratory cyclic testing or in situ tests – FS=CRR/CSR CRR Evaluations for Gravelly Soils 國立中興大學 BPT-Nb – Based on correction between SPT-N and BPTNb (Harder and Seed 1986, Harder 1997) – Need further corrections Normalized shear wave velocity Vs1 – CRR and Vs are affected by same factors – Nondestructive, reliable – Procedure proposed by Andrus and Stokoe (2000) Correction Factors of BPT-Nb30 國立中興大學 Transferred energy N b 30 ENTHRU Nb 30 ENTHRU: % of the measured maximum transferred energy with respect to the hammer effective energy Casing frictional force – Computed by CAPWAP – Effect is minimum in shallow layer 200 Rt=0 180 Rt=0.15MN Rt=0.2MN 160 140 Rt=0.25MN SPT-N60 120 100 80 Rt=0.47MN 60 40 20 0 -20 0 20 40 60 80 100 120 140 160 180 200 BPT-Nb30 Fig.11 Correlation of Several Casing Total Frictional Force for BPT-Nb30 and SPT-N60 Testing Program 國立中興大學 Trench excavation Large hammer penetration test In situ shear wave velocity measurement Cyclic triaxial tests with shear wave velocity measurement 國立中興大學 (Fu-Tin Bridge) Evidences of liquefaction at testing site 國立中興大學 (Fu-Tin Bridge) Current Condition of Testing Site 國立中興大學 Current Condition of Testing Site Table1. Soil Profile in Trench Excavation 國立中興大學 Δ GWT ═ Clay layer Percentage Finer By Weight (%) 100 90 I n s i t u Gr a i n Si z e Di s t r i but i on Cur ve 80 70 60 Si mul a t i on Gr a i n Si z e Di s t r i but i on Cur ve 50 40 30 20 10 0 1000 100 10 1 0.1 0.01 Grain size (mm) Fig. 8 Simulation Curve by Equivalent Weight Substitution Method 0.001 Large Hammer Penetration Test 國立中興大學 In Situ Shear Wave Velocity Measurement 國立中興大學 In situ shear wave velocity near the Wufeng research site were measured by C.P. Lin of the NCTU. Using the Andrus and Stokoe shear wave velocity liquefaction assessment method showed that the safety factor of soil layer liquefaction resistance is less than 1.00. (BH-1 ,amax=0.79g,Z=2.97~13.03m,FS=0.09~0.52) (BH-2 ,amax=0.79g,Z=2.96~12.06m,FS=0.05~0.36) Peak Horizontal Ground Acceleration a max Magnitude Of Earthquake Mw Effective Overburden Pressure kg ) s o' ( cm 2 Shear Wave Velocity from the Research Site V s (m s ) Fine Content FC(%) Fine Content Calculation FC(%) 102.24 MSF 2.56 Mw CSR Induced by the Ground During the Earthquake a s CSR0.65. max. o r d g s o' Overburden Pressure Correction 0.25 p a V s1V s s o' P a 100kpa I c 1.26 FC(%) 0 1.26 I c 3.5 FC(%) 1.75 I c3.25 3.7 I c 3.5 V s1c FC(%) 100 Fine Content Correction 215m FC5% s 2150.5( FC5)m 5 FC35% s 200m FC35% s Soil Layer Liquefaction Strength 2 1 1 V s1 CSR a.. b. 7.5 100 V s1c V s1 V s1c a 0.022;b2.8 Liquefaction Resistance Safety Coefficient CRR7.5 FS .MSF CSR (Andrus and Stokoe ,2000) 國立中興大學 Fig.14 The Profile of Shear Wave Velocity Near the Wufeng Research Site (Lin,et al., 2002) Large-Scale Cyclic Triaxial Test Device 國立中興大學 Triaxial Cell Top plate Accelerometer Porous disc Remolded Specimen Impact source Bottom plate Accelerometer Results of the Cyclic Triaxial Tests 0.5 Cyclic Stress Ratio (CSR) 國立中興大學 0.4 0.3 GC=60% Dr=40% GC=40% Dr=40% GC=20% Dr=40% 0.2 sample remolded by field condition 0.1 1 By field 15 10 100 1000 Number of cycles (N l) CSRN=15 = 0.0036 × (GC%) + 0.0050 × (Dr%) + 0.044 (R2 = 0.968) Results of the Laboratory Vs Measurement Vs (m/s) Effective confining pressure (kg/cm2 ) 100 200 300 0.5 1.5 2.5 3.5 4.5 5.5 400 Effective confining pressure (kg/cm2 ) Vs (m/s) 100 200 300 0.5 1.5 2.5 3.5 4.5 5.5 ▓ Dr=20% GC=20% ▓ Dr=20% GC=40% ▓ Dr=20% GC=40% ▓ Dr=40% GC=40% ● Dr=20% GC=60% ● Dr=60% GC=40% 400 FS Based on Cyclic Triaxial Tests 國立中興大學 Input parameters: – Equivalent number of cycles N1=15 (Mw=7.6) – CSRtri,cor=0.245 (N1=15 cycles) – amax=0.1~0.79 g amax 0.79 0.50 0.33 0.15 0.10 CSR 0.245 0.245 0.245 0.245 0.245 CRR 0.51 0.32 0.21 0.10 0.06 FS 0.48 0.76 1.14 2.52 3.78 FS based on LPT 國立中興大學 BH-4 amax =0.79g BH-2 amax =0.79g Depth(m) 0 1 2 0 3 1 2 BH-4 amax =0.5g BH-2 amax =0.5g 3 0 1 2 0 3 3 3 3 3 4 4 4 4 5 5 5 5 6 6 6 6 7 7 7 7 8 8 8 8 9 9 9 9 10 10 10 10 1 2 3 Table7. In Situ Shear Wave Velocities and FS Bore Hole #1 Bore Hole #2 Depth Vs FS FS Depth Vs (m) (m/sec) (0.79g) (0.5g) (m) (m/sec) FS FS (0.79g) (0.5g) 2.97 214.49 0.18 0.28 2.96 194.97 0.05 0.07 3.86 236.27 0.20 0.32 3.77 249.31 0.26 0.41 4.98 255.99 0.21 0.33 4.78 287.75 0.31 0.50 6.38 265.09 0.18 0.29 6.04 305.22 0.30 0.48 8.12 251.38 0.09 0.15 7.62 339.01 0.33 0.52 10.30 211.71 0.52 0.83 9.59 373.6 0.36 0.57 13.03 338.00 0.24 0.38 12.06 331.44 0.23 0.37 國立中興大學 Conclusions 1. Based on the cyclic triaxial test : CSRfield,GC=53,Dr=31%≒ CSRtri,GC=40,Dr=40% 2. By regression method : CSRNl=15 = 0.0036×(GC%) + 0.0050×(Dr%)+0.044 (R2 = 0.968) 國立中興大學 Conclusions 3. Factors of safety from LPT-Nb30 <1.0 match the field observation LPT2, amax=0.79g, Z=3.00~10.20m,FS=0.1~0.67 4. Factors of safety from Vs <1.0 match the field observation BH-1 ,amax=0.79g, Z=2.97~13.03m,FS=0.09~0.52 國立中興大學 Conclusions 5. With proper corrections, both LPT and Vs methods are adequate for liquefaction evaluation of gravelly soils 6. More research are needed in LPT especially in evaluating the transferred energy and casing friction Future Works 1. Fundamental research of dynamic behavior of gravelly soils Analytical framework on particulate mechanics Numerical analysis to verify the contribution in dynamic shear strain development from gravels 2. Advanced laboratory experiments Measure the variation of shear wave velocity during liquefaction process in cyclic triaxial test Develop experimental technique to determine shear wave velocity of sands in gravelly soils 國立中興大學 Future Works (cont.) 3. Field testing Establish CRR curve for gravelly soils by in situ dynamic liquefaction test Explore other site characterization techniques in liquefaction evaluation for gravelly soils Evaluate the effectiveness of remediation measures in gravelly soils THE END