Two Phase Example

advertisement

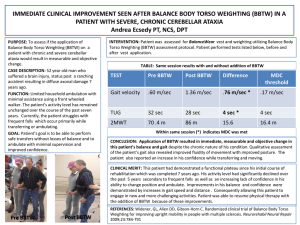

Ref.: Brill & Beggs, Two Phase Flow in Pipes, 6th Edition, 1991. Chapter 3. Two Phase Flow Example 1: Description P2 P1 For the above two-phase pipeline, calculate the exit pressure (P2) based on the Beggs and Brill equation. Compare the manual calculation results with Hysys software results (using Pipe Segment and Pipesys) . Feed specifications: T1 = 60 oF, P1 = 1000 psia, qgtsc= 50 MMscfd, qosc =100000 bbl/day, γgt = 0.7896, γo = 31.3 oAPI, Pipeline specifications: L1 = 900 ft, ΔZ1 = 10 ft, d1= 12 in nominal (Mild Steel, Schedule 40), T2 = 60 oF 2 Two Phase Flow Example 1: Description For using compositional model (in Hysys), the following analysis of produced oil and gas at standard conditions are exist: Distillation Curve and Density (oAPI=31.3) Light Ends Analysis Produced Gas at S. C. Liquid Vol. % Cut Temp, oF Density, oAPI Components Liquid Vol. % Components Mole, % 2.85 145 ---- N2 0.0013 N2 6.8311 3.83 167 57.7 H2S 0.014 H2S 1.3467 5.63 212 56.4 CO2 0.0037 CO2 0.9777 7.33 257 55.4 C1 0.0733 C1 72.8749 10.03 302 52.3 C2 0.0803 C2 7.5713 13.43 347 47.8 C3 0.1307 C3 2.9463 18.53 392 42.6 i-C4 0.4177 i-C4 2.9119 24.43 437 39.2 n-C4 0.3947 n-C4 1.8989 34.23 482 35.8 i-C5 0.9029 i-C5 1.2841 44.93 527 33.0 n-C5 0.7487 n-C5 0.8183 C 6+ 0.5388 Properties of C6+ : Molecular Weight = 89.53, Density = 55.49 oAPI, N. Boiling point = 210 oF 3 Two Phase Flow Example 1: solution In hand calculation, a single segment with Pav= P1 was used (for first iteration). I didn’t find any reliable correlation for calculation of dissolved gas specific gravity, and therefore the specific gravity of free gas was selected from HYSYS software at input conditions: γgf = 0.6397 Calculation of Rs and γgd needs a try and error, based on these equations: P 10 0 .0125 ( API ) 0 . 00091 ( T ) 18 10 o Standing eq. : R s gd Gas mass balance eq. : gd Therefore: 1 / 0 . 83 R s 289 . 3 , gd 0 . 8988 R P gt ( R p R s ) gf Rs q gf sc ( R p R s ) q o sc 21 . 07 MMscfd, B o ( standing ) 1 . 125 q o B o q o sc 112500 bbl/day 7 . 31 ft / sec, o 51 . 355 3 lb m ft 3 4 Two Phase Flow Example 1: solution Volume flow rate of free gas at inlet conditions can be calculated with using Bg: Brown et al method : P pc 672 psia, T pc 367 . 1 R, P pr 1 . 49 , T pr 1 . 42 o Standing and Katz method : z 0 . 82 B g 0 . 01207 q gf B g q gf sc 2 . 943 ft / sec, gf 4 . 049 lb m /ft 3 3 Viscosity of oil and gas and surface tension between them can be calculated as: Standing method : OD 16 . 835 cp o 5 . 56 cp Lee et al method : gf 0 . 06496 gr/cm Baker and Swerdloff 3 gf 0.0127 cp method : OD 31 . 3 o 15 dynes/cm 5 Two Phase Flow Example 1: solution A 0 . 7776 ft , v sL 9 . 4 ft/sec , v sg 3 . 785 ft/sec, v m 13 . 185 ft/sec, L 0 . 713 2 Therefore, the two-phase no slip properties can be calculated as follows: n o L gf g 37 . 78 lb m /ft , n 3 . 97 cp 3 Flow regimes: N Fr 5 . 43 , L1 285 . 3, L 2 0 . 002 , L3 0 . 163 , L 4 4 . 885 , N Lv 24 . 8 L 0 . 4 , N Fr L 4 Distribute d ( Intermitte nt ) Liquid Hold and ρs: H L ( 0 ) H L ( ) 0 . 789 s 41 . 374 lb m /ft 3 dP 0 . 46 lb f /ft d L el 3 6 Two Phase Flow Example 1: solution Pressure gradient due to friction: N Re 1488 d vm n n 1 . 86 10 f n ( smooth ) 0 . 0155 5 y 1 . 145 S ln( 2 . 2 y 1 . 2 ) 0 . 2774 f tp f n e 0 . 0205 S dP 2 . 103 lb f /ft dL f 3 Outlet pressure: E k 4 . 5 10 4 dP dL dP dP d L el d L f 1 Ek 2 . 564 lb f /ft P2 P1 2 . 564 900 / 144 984 psia, PipeSeg : 982, PipeSys 3 984 7