Thermophoretic Deposition - Minnesota State University, Mankato

advertisement

Numerical Treatment of

Thermophoretic Deposition

in Tube Flow

Dr. Patrick A. Tebbe (Faculty Advisor)

Minnesota State University, Mankato

Corey Thiebeault (Graduate Student)

University of Nevada, Reno

November 22, 2011

Presentation Intentions

1. Define thermophoretic deposition and

applications.

2. Review analytical and numerical approaches to

the problem.

3. Examine the problem’s complexity with various

numerical approaches.

Deposition Mechanisms

Deposition

Diffusion

Thermophoresis

Convection

Real World Applications

• Deposition in a tube approximates many modified CVD

and vapor axial deposition (VAD) processes; such as

production of fiber optic strands.

• Deposition of pollutants in the lung; such as Radon.

• Development of micro-electromechanical systems

(MEMS); for application and function.

• Soot deposition in exhaust systems; for purposes of

sampling and reduction.

• Nuclear power accidents; radioisotope transport in

existing and new reactor designs.

Real World Applications

Source: nasa.gov

Source: Gerd Keiser, Optical Fiber Communications,

2d ed., New York: McGraw-Hill, 1991.

Source: www.nrc.gov

Governing Equations

u 0

u

2

u u p u g

o

t

o T u T

t

k T

Navier-Stokes equations of continuity, conservation

of momentum, and energy.

Conservation of Species

1

r u V Tr n v V Tz n 1 rD n D n

r r

z

r r

r z

z

T

D

Cc

3 d p

2.94

V Tr

lnT

r

k k p 2.20Kn1 Kn1.2 0.41exp(0.88 / Kn)

1 3.438Kn1 2k k p 4.40Kn

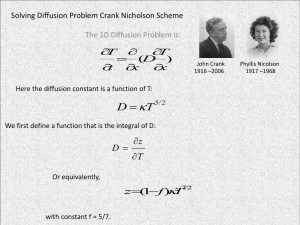

Diffusive Deposition

P 1 5.5 2 / 3 3.77

for 0.007

P 0.819exp(11.5 ) 0.0975exp(70.1 )

0.0325exp(179 )

for 0.007

DL

Q

Isothermal diffusive transport to the walls (Hinds)

Graetz Problem

( x, r ) 2

exp( 2n x) F (r , n)

n 1

n n

Laminar flow with a step change in temperature at the

wall. While a finite number of terms is needed they

can prove difficult to calculate. (Housiadas et al.)

The extended Graetz problem includes axial

conduction.

Boundary Layer Theory

Tube flow is split up into three distinct layers:

1. Convection dominated with no change in radial

concentration (core).

2. Thermophoretic layer with diffusion neglected.

3. Diffusion layer with convection neglected (wall).

Boundary Layer Theory

The Graetz solution is used to solve for

temperature (*). For PrK=1 the deposition

efficiency is found to be:

1 xˆ

( xˆ) (4.07)

*

1 Peth

23

Where axial location and temperature are nondimensionalized (Williams and Loyalka)

Numerical and Experimental

Strattmann et al. studied cooled laminar tube flow

(30 to 100 nm particles)

• Found little influence by all axial effects (heat

conduction, diffusion, and thermophoresis)

• Material property changes were negligible

• An empirical formula was developed

NOTE: DT values were 20° to 100° C

Numerical and Experimental

Shimada et al. studied axially varying wall

temperatures (7 to 40 nm particles)

• Strong temperature influence on diffusion

coefficient was found.

• Empirical correlations show that

thermophoretic deposition cannot be

superposed on Brownian deposition.

NOTE: The maximum furnace temperature used

was 950° C

Numerical and Experimental

He and Ahmadi studied both laminar and

turbulent flows determining that:

• Smaller particles (0.01 m) are dominated by

diffusion.

• Larger particles (0.1 ≤ d ≤ 1 m) are dominated

by the thermophoretic force.

• Away from the wall, turbulence dominates

dispersion

• Near the wall, Brownian diffusion dominates

Numerical Approach #1

A de-coupled Eulerian approach was initially

chosen:

• Solution of flowfield and temperature in

FLOTRAN (ANSYS finite element module).

• Solution of species transport in separate finite

difference program (FORTRAN).

Numerical Approach #1

• Axi-symmetric geometry.

• Parabolic velocity profile at the inlet, zero

pressure at the outlet, no-slip on walls.

• Fluid assumed to be air with variable properties.

• Axial diffusion and thermophoresis are neglected.

• Negligible radial convection.

• Monodisperse inlet concentration of 1.0.

Program Verification

• The program was verified against the data of

Walker et al.

• Axial length set to 1 meter.

• Tube radius set to 0.01 meter.

• Particle diameters ranged from 1 to 50 nm.

Diffusion vs. Thermodiffusion

Inlet temperature = 293 K

Flowrate = 0.1 L/min

Particle diameter = 5 nm

Twall (K)

Pdiffusion

Pthermodiffusion

373

0.8425

0.8438

573

0.6825

0.6887

973

0.5566

0.5751

Note: P represents the “penetration” of particles.

Particle Diameter Effects

Penetration

1

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

Thermophoretic

0.1

0

Diffusion only

0

10

20

30

40

50

Particle diameter (nm)

Inlet temperature = 293 K, Twall = 973 K

Flowrate = 0.5 L/min

Flowrate Effects

Percent change in penetration

(Inlet temperature = 293 K and particle diameter = 5 nm)

Twall (K)

0.1 L/min

0.5 L/min

373

0.15

0.85

573

0.9

2.22

973

3.32

6.98

(Pthermodiffusion – Pdiffusion)/Pdiffusion x 100%

Numerical Approach #2

A spectral collocation method has recently been explored:

• Spectral methods chose a basis function that is global

to the entire computational domain.

• Spectral methods select basis functions that are high

degree polynomials or trigonometric polynomials that

are infinitely differentiable.

• Progress to date has included studying the extended

Graetz problem and simple diffusion deposition.

Radial temperature profiles

Temperature profiles at different axial positions

Affect of axial conduction

Bulk fluid temperatures (non-dimensional) along

centerline of tube. Compared to a finite element

method on the right.

Affect of axial conduction (Pe=50)

Temperature profiles at different axial positions

Time comparison to finite difference

The finite difference method used a Jacobian

solution method.

The spectral method showed greater accuracy at

low grid size and shorter computation times.

Conclusions on spectral method

• The spectral collocation method showed good

agreement with other methods.

• The spectral method showed advantages in

terms of computational solution times.

• Its use would be limited by complex geometries.

Questions ?

References

He, C. and Ahmadi, G., 1998, “Particle Deposition with Thermophoresis in Laminar and Turbulent Duct

Flows,” Aerosol Science and Technology, 29, pp. 525-546.

Hinds, W.C., (1999). Aerosol Technology, 2nd Ed., John Wiley & Sons, New York.

Housiadas, C., Larrode, F. E., Drossinos, Y., (1999), Technical Note Numerical

Evaluation of the Graetz Series, Int. J. Heat Mass Transfer, Vol. 42, pp. 3013‐

3017.

H.-C. Ku and D. Hatziavramidis, “Chebyshev expansion methods for the solution of the extended

graetz problem," Journal of Computational Physics, vol. 56, no. 3, pp. 495 - 512, 1984.

M. . Y Bayazitoglu, “On the solution of graetz type problems with axial conduction," International

Journal of Heat and Mass Transfer, vol. 23, pp. 1399{1402, 1980.

S. Singh, “Heat transfer by laminar flow in a cylindrical tube," Applied Scientific Research, vol. 7, pp.

325-340, 1958.10.1007/BF03184993.

Shimada, M., Seto, T., and Okuyama, K., 1993, “Thermophoretic and Evaporational Losses of

Ultrafine Particles in Heated Flow,” AIChE Journal, 39, pp. 1859-1869.

Stratmann, F. and Fissan, H., 1988, “Convection, Diffusion and Thermophoresis in Cooled Laminar

Tube Flow,” Journal of Aerosol Science, 19, pp. 793-796.

Williams, M.M.R. and Loyalka, S.K., Aerosol Science: Theory and Practice, Pergamon, 1999.