File

advertisement

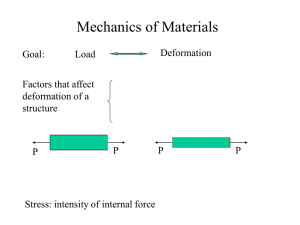

Theories of Failure Failure of a member is defined as one of two conditions. 1. Fracture of the material of which the member is made. This type of failure is the characteristic of brittle materials. 2. Initiation of inelastic (Plastic) behavior in the material. This type of failure is the one generally exhibited by ductile materials. When an engineer is faced with the problem of design using a specific material, it becomes important to place an upper limit on the state of stress that defines the material's failure. If the material is ductile, failure is usually specified by the initiation of yielding, whereas if the material is brittle it is specified by fracture. 1 These modes of failure are readily defined if the member is subjected to a uniaxial state of stress, as in the case of simple tension however, if the member is subjected to biaxial or triaxial stress, the criteria for failure becomes more difficult to establish. In this section we will discuss four theories that are often used in engineering practice to predict the failure of a material subjected to a multiaxial state of stress. A failure theory is a criterion that is used in an effort to predict the failure of a given material when subjected to a complex stress condition. 2 Several theories are available however, only four important theories are discussed here. i. Maximum shear stress (Tresca) theory for ductile materials. ii. Maximum principal stress (Rankine) theory. iii. Maximum normal strain (Saint Venan’s) theory. iv. Maximum shear strain (Distortion Energy) theory. 3 Maximum shear stress theory for Ductile Materials The French engineer Tresca proposed this theory. It states that a member subjected to any state of stress fails (yields) when the maximum shearing stress (τmax)in the member becomes equal to the yield point stress (τy)in a simple tension or compression test (Uniaxial test). Since the maximum shear stress in a material under uniaxial stress condition is one half the value of normal stress and the maximum normal stress (maximum principal stress) is max, then from Mohr’s circle. max max 2 4 5 In case of Biaxial stress state max max min 2 1 2 2 (2) max y 1 2 2 y 2 1 2 y (3) If both of principal stresses are of the same sign tension compression then σ1 <σy (4) σ2 <σy (5) 6 A graph of these equation is given in the figure. Any given state of stress will be represented in this figure by a point of co-ordinate 1 and 2 where 1 and 2 are two principal stresses. If these point falls within the area shown, the member is safe and if outside then member fails as a result of yielding of material. The Hexagon associated with the initiation of yield in the member is known as “Tresca Hexagon”. (1814- 1885). In the first and third quadrant 1 and 2 have the same signs and 7 max is half of the numerically larger value of principal stress 1 or 2. In the second and fourth quad, where 1 and 2 are of opposite sign, max is half of arithmetical sum of the two 1 and 2. In fourth quadrant, the equation of the boundary or limit (yield/boundary stress) stress line is 1 - 2 = y And in the second quadrant the relation is 1 - 2 = -y 8 2 y 1 2 y 1 y 1 2 y 1 y 2 y 9 Problem 01:The solid circular shaft in Fig. (a) is subject to belt pulls at each end and is simply supported at the two bearings. The material has a yield point of 36,000 Ib/in2• Determine the required diameter of the shaft using the maximum shear stress theory together with a safety factor of 3. 10 400 + 200 lb 200 + 500 lb 11 12 x c I Mc I d 2 d 4 64 M B 600 6 3600 lb.in Mc 700 6 4200 lb.in x x 4200 d d 4 2 64 42800 d3 y 0 13 xy Tr J xy 4800 d d 4 yx 2 32 xy x 24,480 d3 yx T (500 200) 16 300 16 4800 lb.in OR xy 24,480 d3 xy 42,800 x d3 ( 400 200) 24 200 24 4800 lb.in 14 As we know 1 2 2 max x y xy 2 1 2 2 2 2 And y F .O.S . max yield F .O.S . 2 ( 1 2 ) 2 yield 36000 1 2 FOS 3 15 2 2 2 2 42800 24,480 1 2 2 3 3 2d d 36,000 42800 24,480 2 3 3 3 2d d 2 12,000 42800 24,480 3 3 2 2d d 2 2 42800 24,480 3610 3 3 2d d 2 6 d 1.76' ' 16 Problem 02 The state of plane stress shown occurs at a critical point of a steel machine component. As a result of several tensile tests, it has been found that the tensile yield strength is y = 250 MPa for the grade of steel used. Determine the factor of safety with respect to yield, using (a) the maximum-shearing-stress criterion, and (b) the maximum-distortionenergy criterion. 17 18 SOLUTION Mohr's Circle. We construct Mohr's circle for the given state of stress and find ave OC 12 ( x y ) 12 (80 40) 20MPa m R (CF ) 2 ( FX ) 2 (60) 2 (25) 2 65 MPa Principal Stresses a OC CA 20 65 85MPa b OC CA 20 65 45MPa a. Maximum-Shearing-Stress Criterion. Since for the grade of steel used the tensile strength is ay = 250 MPa, the corresponding shearing stress at yield is Y 12 Y 12 (250MPa) 125 MPa 19 For m 65MPa Y 125MPa F .S m 65 MPa F .S 19.2 20 b. Maximum-Distortion-Energy Criterion. Introducing a factor of safety into Eq. (7.26), we write Y a b F .S 2 a 2 2 b For a = +85 MPa, b = -45 MPa, and y = 250 MPa, we have 250 85 85 45 45 F.S 2 2 2 250 114 .3 F .S F .S 2.19 21 Comment. For a ductile material with y = 250 MPa, we have drawn the hexagon associated with the maximum-shearing-stress criterion and the ellipse associated with the maximum-distortion-energy criterion. The given state of plane stress is represented by point H of coordinates a = 85 MPa and b = -45 MPa. We note that the straight line drawn through points O and H intersects the hexagon at point T and the ellipse at point M. For each criterion, the value obtained for F.S. can be verified by measuring the line segments indicated and computing their ratios: OT a F .S 19.2 OH OM b F .S 2.19 OH 22 23 Example 10-12 The solid shaft shown in Fig. 10-41a has a radius of 0.5 in. and is made of steel having a yield stress of y = 36 ksi. Determine if the loadings cause the shaft to fail according to the maximum-shear-stress theory and the maximum-distortion-energy theory. Solution The state of stress in the shaft is caused by both the axial force and the torque. Since maximum shear stress caused by the torque occurs in the material at the outer surface, we have 24 P 15 kip x 19.10 ksi 2 A (0.5 in.) xy Tc 3.25 kip.in.(0.5 in.) 16.55 ksi 4 J (0.5 in.) / 2 The stress components are shown acting on an element of material at point A in Fig. 10-41b. Rather than using Mohr's circle, the principal stresses can also be obtained using the stress-transformation equations, Eq.9-5. 1, 2 x y 2 x y xy 2 2 2 2 1, 2 19.10 0 19.10 0 2 (16.55) 2 2 25 = -9.55 ± 19.11 CTI = 9.56 ksi CT2 = -28.66 ksi Maximum-Shear-Stress Theory. Since the principal stresses have opposite signs, then from Sec. 9.5, the absolute maximum shear stress will occur in the plane, and therefore, applying the second of Eq. 10-27, we have 1 2 Y 9.56 28.66 36 ? 38.2 36 26 Thus, shear failure of the material will occur according to this theory. Maximum-Distortion-Energy Theory. Applying Eq. 10-30, we have ( 12 1 2 22 ) y 9.56 9.56 28.66 28.66 (36) 2 2 ? 2 1187 1296 Using this theory, failure will not occur. 27 Maximum Principal Stress theory or (Rankine Theory) According to this theory, it is assumed that when a member is subjected to any state of stress, fails (fracture of brittle material or yielding of ductile material) when the principal stress of largest magnitude. (1) in the member reaches to a limiting value that is equal to the ultimate normal stress, the material can sustain when subjected to simple tension or compression. 1 ult (1) 2 ult The equations are shown graphically as (2) 28 ult These equations are shown graphically if the point obtained by plotting the values of 1 + 2 falls within the square area the member is safe.29 It can be seen that stress co-ordinate 1 and 2 at a point in the material falls on the boundary for outside the shaded area, the material is said to be fractured failed. Experimentally, it has been found to be in close agreement with the behavior of brittle material that have stress-strain diagram similar in both tension and compression. It cab be further noticed that in first and third quad, the boundary is the save as for maximum shear stress theory. Problem A thin-walled cylindrical pressure vessel is subject to an internal pressure of 600 lb/in2. the mean radius of the cylinder is 15in. If the material ha a yield point of 39,000lb/in2 and a safety of 3 is employed, 30 determine the required wall thickness using (a) the maximum normal stress theory, and (b) the Huber-von Mises-Hencky theory. P = 600psi. r = 15" y = 39000psi F.O.S = 3 t=? According to Pr c t where c Circumferential stress / girth stress 31 600 15" 9000 c t t For lengitudinal stress Pr l 2t 600 15" 4500 c 2t t By comparing 1 = c. Thus, According to the normal stress theory, maximum Principal stress should be equal to yield stress/FOS i.e. |1| ≤ ult |2| ≤ ult f = maximum (|1|, |2|, |3| - ult = 0) 32 As y = 39000psi 39000 9000 3 t 13000 9000 t t 0.69 Ans. Problem 02:The solid circular shaft in Fig. 18-12(a) is subject to belt pulls at each end and is simply supported at the two bearings. The material has a yield point of 36,000 Ib/in2• Determine the required diameter of the shaft using the maximum normal stress theory together with a safety factor of 3. 33 400 + 200 lb 200 + 500 lb 34 35 x c I Mc I d 2 d 4 64 M B 600 6 3600 lb.in Mc 700 6 4200 lb.in x x 4200 d d 4 2 64 42800 d3 y 0 36 xy Tr J xy 4800 d d 4 yx 2 32 xy x 24,480 d3 yx T (500 200) 16 300 16 4800 lb.in OR xy 24,480 d3 xy 42,800 x d3 ( 400 200) 24 200 24 4800 lb.in 37 1 2 x y 2 x y 2 x y xy 2 2 2 x y xy 2 2 2 2 42800 42800 24446.20 1 3 3 3 2d d 2d 2 According to maximum normal stress theory . ult 1 2 36000 42800 42800 24446.20 3 3 3 3 2d d 2d 2 38 2 42800 42800 24446.20 12000 3 3 3 2d d 2d 2 6 6 6 915 . 92 10 457 . 96 10 597 . 62 10 144106 3 6 2d d d6 9 1 . 514 10 144106 d6 d 6 10.51 d 1.48" 39 Mohr’s Criterion:In some material such as cast iron, have much greater strength in compression than tension so Mohr proposed that is 1st and third quadrant of a failure brokes, a maximum principal stress theory was appropriate based on the ultimate strength of materials in tension or compression. Therefore in 2nd and 4th quad, where the maximum shear stress theory should apply. Pure shear is one in which x and y are equal but of opposite sense. 40 Failure or strength envelope Pure shear ult c Smaller tension strength Largest compressive strength 41 tension compression 42 Problem 3:In a cast-iron component the maximum principal stress is to be limited to one-third of the tensile strength . Determine the maximum value of the minimum principal stresses ,using the Mohr theory. What would be the values of the principal stresses "associated with a maximum shear stress of 390 MN/m2? The tensile and compressive strengths of the cast iron are 360 MN/m2 and 1.41 GN/m2 respectively 43 ult t 360 MN / m 2 ult c 1414106 MN / m 2 As indicat ed that 1 ult ( t ) 3 360 120MN / m 2 3 2 ? As per Mohr's criterion 1st and thirdquadrant Normalstress 2 nd and fourthquadrant Shearingstress 44 By using principal stress theory ult 1 (a) ult 2 (b) As ult t 360 MN / m 2 ult c 414 MN / m 2 Maximum principal stress = 360/3 = 120 MN/m2 (tension). According to Mohr's theory, in the second and fourth quadrant 1 120 MN / m2 From (a) and (b) 45 1 1 ult t and 2 1 ult c 1 2 1 ult t ult c Therefore 120 2 1 and 2 940 MN / m 2 360 1410 The Mohr's stress circle construction for the second part of this problem is shown in Fig. 13.7. If the maximum shear stress is 390 MN/m2, a circle is drawn of radius 390 units to touch the two envelope lines. The principal stresses can then be read off as +200 MN/m2 and -580 MN/m2• 46 max 390 ult t ult c ult c 1410 ult t 360 47 Fig 13.7 48 Now from second state max 390 MN / m 2 By shearingst ress t heory ult t 1 2 and in fourt hquad ult c 1 2 Thus 380 1 2 1414 1 2 Also max 2R 1 2 1 2 2 49 Example 10-11 The solid cast-iron shaft shown in Fig. 10-40a is subjected to a torque of T = 400 Ib . ft. Determine its smallest radius so that it does not fail according to the maximum-normal-stress theory. A specimen of cast iron, tested in tension, has an ultimate stress of (σult)t = 20 ksi. Solution The maximum or critical stress occurs at a point located on the surface of the shaft. Assuming the shaft to have a radius r, the shear stress is max Tc (400 lb. ft )(12in. / ft )r 055.8 lb.in. 4 J ( / 2)r r3 50 51 52 Mohr's circle for this state of stress (pure shear) is shown in Fig. 1040b. Since R = max, then 1 2 max 3055 .8lb.in. r3 The maximum-normal-stress theory, Eq. 10-31, requires |1| ≤ ult 3055 .8lb.in. 2 20 , 000 lb / in r3 Thus, the smallest radius of the shaft is determined from 3055.8lb.in. 2 20 , 000 lb / in r3 r 0.535 in. Ans. 53 Example 10-12 The solid shaft shown in Fig. 10-41a has a radius of 0.5 in. and is made of steel having a yield stress of y = 36 ksi. Determine if the loadings cause the shaft to fail according to the maximum-shear-stress theory and the maximum-distortion-energy theory. Solution The state of stress in the shaft is caused by both the axial force and the torque. Since maximum shear stress caused by the torque occurs in the material at the outer surface, we have 54 P 15 kip x 19.10 ksi 2 A (0.5 in.) xy Tc 3.25 kip.in.(0.5 in.) 16.55 ksi 4 J (0.5 in.) / 2 The stress components are shown acting on an element of material at point A in Fig. 10-41b. Rather than using Mohr's circle, the principal stresses can also be obtained using the stress-transformation equations, Eq.9-5. 1, 2 x y 2 x y xy 2 2 2 2 1, 2 19.10 0 19.10 0 2 (16.55) 2 2 55 = -9.55 ± 19.11 CTI = 9.56 ksi CT2 = -28.66 ksi Maximum-Shear-Stress Theory. Since the principal stresses have opposite signs, then from Sec. 9.5, the absolute maximum shear stress will occur in the plane, and therefore, applying the second of Eq. 10-27, we have 1 2 Y 9.56 28.66 36 ? 38.2 36 56 Thus, shear failure of the material will occur according to this theory. Maximum-Distortion-Energy Theory. Applying Eq. 10-30, we have ( 12 1 2 22 ) y 9.56 9.56 28.66 28.66 (36) 2 2 ? 2 1187 1296 Using this theory, failure will not occur. 57 Maximum Normal Strain or Saint Venant’s Criterion In this theory, it is assumed that a member subjected to any state of stress fails (yields) when the maximum normal strain at any point equals, the yield point strain obtained from a simple tension or compression test (y = σy/). Principal strain of largest magnitude |max| could be one of two principal strain 1 and 2 depending upon the stress conditions acting in the member . Thus the maximum Principal strain theory may be represented by the following equation. 58 max 1 y max 2 y (1) As stress in one direction produces the lateral deformation in the other two perpendicular directions and using law of superposition, we find three principal strains of the element. σx σy σz x= σx / E x= μσy / E y= -μσx / E y= σy / E x= –μσ / E z y= -μσ / E z= -μσx / E z= -μσy / E z= σ / E 59 z z x y z = σx / E -μσy / E = σx / E -μ / E (σy + σz) = σy / E -μσx / E = σy / E -μ / E (σx + σz) = σz / E -μσy / E = σz / E -μ / E (σx + σy) Thus -μσz / E -μσz / E (2) -μσx / E 1 1 E ( 2 3 ) E 2 2 ( 1 3 ) E E 3 3 E ( 2 1 ) E (3) 60 Also 1 1 E 2 ( For 2 d ) E ( 4) Equat ing 1 and 4 y 1 y E 1 E and 2 2 2 E E 1 E T hen y 1 2 (5) y 2 1 ( 6) 61 The yield surface ABCD is the straight under biaxial tension or biaxial compression Individual principal stresses greater than σy can occur without causing yielding. 62 Maximum Shear Strain Energy (Distortion Energy Criterion (Von MISES Criterion) According to this theory when a member is subjected to any state of stress fails (yields) when the distortion energy per unit volume at a point becomes equal to the strain energy of distortion per unit volume at failure (yielding) in uniaxial tension (or compression). The distortion strain energy is that energy associated with a change in the shape of the body. The total strain energy per unit volume also called strain energy density is the energy in a body stored internally throughout its volume due to deformation produced by external loading. If the axial stress 63 arising in a tension test is “” and the corresponding axial strain is ε then the work done or a unit volume of the test specimen is the product of mean value of the force per unit area (/2) times the displacement in the direction of the force, or ε. The work is thus U 2 (1) This work is stored as internal strain energy. When an elastic element subjected to triaxial loading as show in Fig the stresses can be resolves in to three principal stresses σ1,σ2 and σ3. where 1,2 and 3 are the principal axes. These three principal stresses will be accompanied by these principal strain related to the stresses by equations 3,4and 5 64 u ( 2 3 ) 1 E E (2) 2 u ( 1 3 ) 2 E E (3) 3 (4) 1 u ( 1 2 ) 3 E E If it is assumed that loads are applied gradually and simultaneous then stresses and strain will increase in the same manner. The total strain energy per unit volume in the sum of energies produced by each of the stresses (as energy is a scalar quantity ) 65 1 1 1 U , , 2 , 2 , 3 , 3 2 2 2 (5) Where ε1, ε2, and ε3, are the normal strain in the direction of principal stresses respectively of strain are expressed in term of stresses than equation (5) taken the following form 1 1 2 3 1 2 1 3 1 3 1 2 U ( 1 ) 2 3 2 E 2 E E 2 E E E E E E Which can be reduced to 1 U 12 22 33 2 ( 1 2 1 3 2 3 ) 2E (6) 66 As the deformation of a material can be separated in to two parts (a) Change in volume, (b) change in shape or distortion. Similarly the total strain energy can be broken in to two parts. One part representing the energy needed to cause volume change of the element with no change in shape (Uv) and the other part representing the energy needed to distort the element (Ud). U Uv Ud (7) The principal stresses σ1,σ2 and σ3 of Fig. (01) can be resolved in to two states of stresses in Fig. (02) b & c. the state of stress shown in Fig. b represents a hydrostatic stress condition in which all these principal stress are equal to the quantity σ. 67 3 1 1 (a) 3- (b) 2- 1- (c) 68 Some materials were subjected to hydrostatic pressure resulting in appreciable changes in volume but no change in shape and no failure by yielding. Therefore the remaining portion of the stress (1 - ), (2 - ) and (3 - ) will result in distortion only (No volume change) and the algebraic sum of the three principal strains produced by the three principal stresses (1 - ave), (2 - ave) and (3 - ave) must be equal to zero. i.e (ε1+ε2+ε3)d=0 (9) Expressing strains in term of stresses. 69 E 1 2 3 d 1 2 3 2 3 1 3 1 2 0 1 2 3 2 2 3 1 2 3 1 2 2 1 2 3 2 2 3 1 2 3 1 2 2 1 1 1 2 2 2 3 3 3 3 6 1 2 1 2 2 2 3 2 3 3 6 70 a) One part that causes Volumetric (Uv) b) Change and one causes distortion an (Ud) U Uv Ud (4) a) As according to theory of distortion only energy due to distortion is responsible for failure. Some experimental evidence supports this assumption some materials were subjected to hydrostatic pressure result in appreciable changes in volume but no change in shape and no failure by yielding. The hydrostatic pressure is the average of three principal stresses 1 2 and 3 known as average stress. max 1 2 3 3 (5) 71 This principal strains ε in the material. Due to there Principal stresses (1, 2, 3) three principal strains ε1, ε2, and ε3, are produced. The state of stress in Fig below will result in distortion only (No volume change) if sum of three normal strains is zero. That is 1 1 2 u 2 3 2 2 1 3 2 E ( 1 2 3 ) 0 E 3 1 2 2 (6) Which eh reduces to (1 2 ) 1 2 3 3 0 1 2 3 / 3 (5) 72 The normal strains corresponding to these stresses are found from three dimension from of Hook’s law given by the following equation. (1 2 ) E (7) Strain energy resulting from these stresses or strains can be obtained by subject through these values is 1 2 3 , 1 2 3 1 1 1 3 Uv . . . . 2 2 2 2 (8) 73 3 ( 1 2 3 ) (1 2u ) ( 1 2 3 ) Uv . 2 3 E 3 (5) (1 2u ) Uv ( 1 2 3 ) 2 6E (9) Strain energy due to distortion U=Uy + Ud Ud = U- Uy 1 1 2u 2 2 2 2 Ud 1 2 3 2u 1 2 1 3 2 3 1 2 3 6E 2E (10) Ud 1 2 3( 12 22 32 ) 6u ( 1 2 1 3 2 3 ) 1 2u 1 2 743 6E When the third force in the Ud 1 u 12 2 1 2 22 22 2 2 3 32 32 2 3 1 12 6E 1 u 1 2 2 2 3 2 3 1 2 Ud 6E (12) (13) For biaxial stress system, σ3 = 0 (14) 1 u 2 Ud 1 3E (15) 1 u 2 Ud 1 2 1 2 22 3E For uniaxial stress system 75 For Distortion theory the failure occurs when distortion energy of the member however equal to the strain energy of distortion at failure (yielding) in uniaxial torsion (or equilibrium). So substituting σ1=σy in equ (15) 1 u Ud 2 y2 6E (16) And equating it with (13) 1 u 1 u 2 1 2 2 2 3 2 3 1 2 (2 y ) 6E 6E 2 1 2 2 3 3 1 2 y 2 2 2 (17) 76 For biaxial stress system y2 12 2 1 2 22 (18) 77