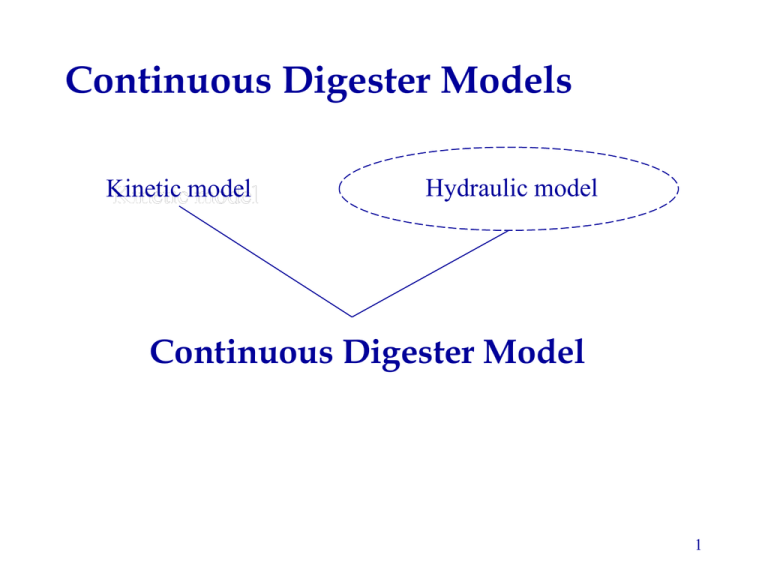

Continuous Digester Model

advertisement

Continuous Digester Models Kinetic model Hydraulic model Continuous Digester Model 1 Continuous Digester Models The problem • As chips descend to the bottom of the digester they get softer with cooking. Forces on chips cause them to conform dramatically reducing void fraction ε in the bed. • The void volume in the chip doesn’t appear to change much. Pores in the chip don’t collapse. Chip Flow 2 Continuous Digester Models • As ε (void fraction in the bed) is reduced, the residence time in that zone increases and the flow of liquor is reduced. » ε can be reduced to a level such that the digester is plugged. 3 Continuous Digester Models • Fundamental work on Kamyr hydraulics has been done by Harkonen. •Chips at various kappa numbers can be placed in apparatus •Chips in digester can be compressed •Void fraction in bed is measured •Flow rate through the bed is measured 4 Continuous Digester Models: Compressibility v 0.644 ( p / 10 ) 4 0.59 (void fraction in chip bed) Pressure (0.831 0.139 ln k ) Kappa 5 Continuous Digester Models: Flow Resistance p 2 2 6 2 4600 ( c / v )V 3.9 *10 ( c / v )V l Where: Pressure drop per unit length εc = volume fraction of the chip V = velocity of liquor εc + εv = 1 6 Continuous Digester Models • Combine experimental results with: » Mass balance » Force (momentum) balance » Heat balance • Predict chip pressure, Σ of all forces on chip 7 Continuous Digester Models Unfavorable conditions if chip pressure is too high or low • Chip pressure too large then the digester will plug (no flow) • Chip pressure < 0 then the digester will hang 8 Models Results A: Chip pressure in meters water column B: Chip volume fraction in percent 9 Models Results A: Liquor Velocity in mm/s B: Chip velocity in mm/s C: Relative velocity difference between chip and liquor in mm/s 10 Models Results A: Chip temperature in °C B: Cumulative H-factor 11