RESD 2313 lecture 2

advertisement

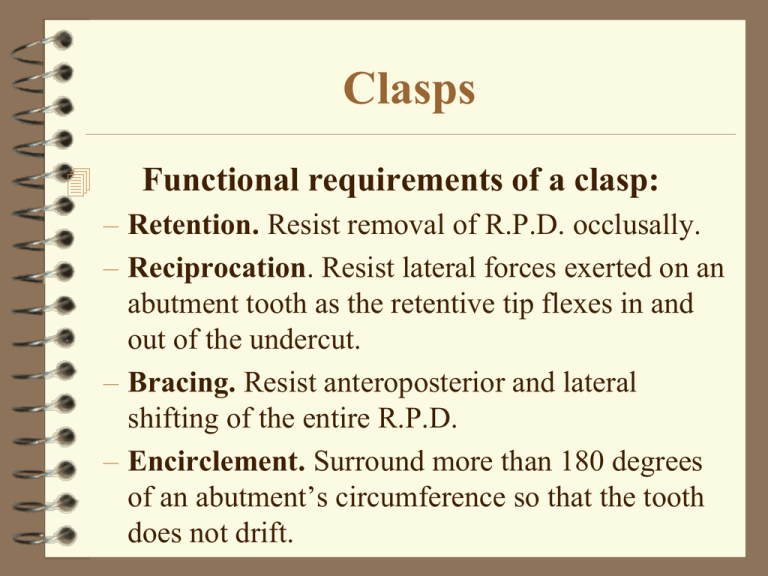

Clasps Functional requirements of a clasp: – Retention. Resist removal of R.P.D. occlusally. – Reciprocation. Resist lateral forces exerted on an abutment tooth as the retentive tip flexes in and out of the undercut. – Bracing. Resist anteroposterior and lateral shifting of the entire R.P.D. – Encirclement. Surround more than 180 degrees of an abutment’s circumference so that the tooth does not drift. Clasp Assembly The clasp assembly includes rest and minor connectors The functional requirements of the clasp assembly also includes Support Support is achieved through the rest component Major clasp classifications Circumferential clasps (Suprabulge or Akers) Bar clasps (infrabulge or Roach) Circumferential clasps (Suprabulge or Akers ) Body, retentive arm, retentive tip, reciprocal arm, and shoulder. Approaches the undercut from the occlusal portion of the tooth. Examples: simple circlet (circumferential), back action ,embrasure etc . Bar clasps (infrabulge or Roach) Body, approach arm, retentive tip, bracing tip, reciprocal arm, and shoulder. Approaches the undercut from the gingival portion of the tooth. Examples: I-bar, T-bar, Modified T The clasp arm is tapered to increase flexibility A continuous clasp needs bracing on all teeth that it contacts. Block-out 1. Bulk block out major undercuts 2. Block out undercuts around abutment teeth. 3. Relief wax on saddle areas. 24gauge. – a. Internal finish lines- provide a definite joint between the metal and resin portion of the appliance. – b. Tissue stop are placed on the ridge of distal extension by cutting a 2 x 2mm square in the relief wax Duplication 1 Soak stone cast for 30 minutes in SDS water, 90 degrees F, to eliminate air from the casts and replace it with water so casts will not draw moisture from hydrocolloid and adhere to the cast. Duplication Dupli-All duplicating material is an Agar Hydrocolloid. The pouring temperature is 50 degrees Celsius. Melt down temperature is 90 degrees Celsius. Duplication Duplicating material must cool Red-stripe investment is a phosphate- bonded investment The liquid used with Red-stripe investment is water. Wax dip Dehydrate the refractory cast to prepare for wax dipping Place in dehydration oven for 1 hour Wax dipping ensures a smooth dense cast Wax-up Use combination of pre-formed pattern and free flown wax. Sprue and Invest A sprue provides a passageway for molten metal during casting Auxillary sprues are used to ensure complete casting to thicker areas The ratio for outer investment is 60 cc of 30% Begosol solution to 400 grams of investment Burnout Thermal expansion of investment occurs during burnout. Casting Induction casting machine uses 220 volts of electricity. The electric casting machine also uses water Bego casting machine used positive pressure from above and vacuum from below Casting A dark shadow will disappear when metal is ready to cast. Casting Acetylene and oxygen can be used to melt Cobalt-chromium metal. 50% new chrome cobalt should be added to an existing button to make a casting