Mechanical Properties of Metals

advertisement

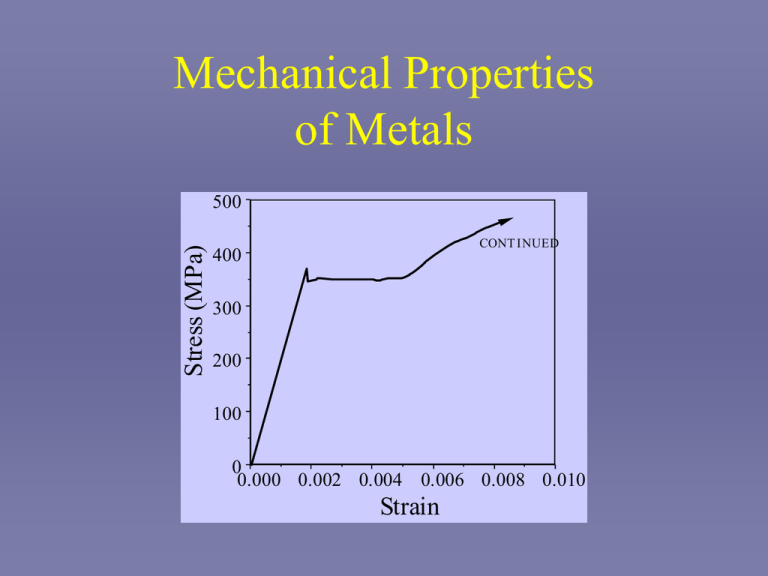

Mechanical Properties of Metals Stress (MPa) 500 CONT INUED 400 300 200 100 0 0.000 0.002 0.004 0.006 0.008 0.010 Strain Mechanical Properties • Stiffness - Elastic Modulus or Young’s Modulus (MPa) • Strength - Yield, Ultimate, Fracture, Proof, Offset Yield. Measured as stress (MPa) • Ductility - Measure of ability to deform plastically without fracture - Elongation, Area Reduction, Fracture Strain - (no units or mm/mm) • Toughness, Resilience - Measure of ability to absorb energy (J/m3). • Hardness - Resistance to indentation/abrasion (Various scales, e.g.; Rockwell, Brinell, Vickers.) Stress and Strain • In a simplistic sense, stress may be thought of as Load/Area. • Similarly, strain is the deformation of the component/original length. • A stress may be direct, shear, or torsional leading to corresponding deformations. • Stress cannot be measured directly, but deformation can be. Direct Stress Examples Load, P L/2 Lo Area Ao L/2 P Engineering Stress P S Ao Load, P L/2 Lo L e Lo Area Ao L/2 Engineering Strain P Direct Stress - Tension Direct Stress - Compression Tension Test Measures P Extensometer Measures L Typical Universal Testing Machine Modern Materials Testing System Hydraulic Wedge Grips Extensometer Specimen ASTM Tension Test Specimen Ao=0.20 in2 0.505" Dia 2” Gauge Length Lo Raw Data Obtained Load, P (kN) Total Elongation Uniform Deformation X Maximum Load, Pmax Elastic Deformation Elongation, L (mm) Load, Pf Engineering Stress-Strain Curve Engineering Stress, S=P/Ao Elongation Sy 0.2% offset yield stress (Ultimate) E Su E Proportional Limit Engineering Strain, e = L/Lo) Duke’s Quick Tip! • Express Load in Newtons (N) and Area in mm2 to get Stress in MPa. N 2 MPa mm • Mechanical properties of metals are almost always given in MPa or ksi. • Imperial units: Load in kips (1000 lbf) & Area as in2 gives Stress in ksi (kips/in2) • 1000 psi = 1 ksi = 6.89 MPa Hooke’s Law Elastic Deformation • Elastic deformation is not permanent; it means that when the load is removed, the part returns to its original shape and dimensions. • For most metals, the elastic region is linear. For some materials, including metals such as cast iron, polymers, and concrete, the elastic region is non-linear. • If the behavior is linear elastic, or nearly linear-elastic, Hooke’s Law may be applied: S Ee • Where E is the modulus of elasticity (MPa) Modulus of Elasticity - Stiffness Stress (MPa) 500 CONT I NUED 400 300 200 E S (300 0)MPa 2x10 5 MPa e (0.015 0.0) 100 0 0.000 0.002 0.004 0.006 Strain 0.008 0.010 Atomic Origin of Stiffness Net Interatomic Force dF E dr ro Strongly Bonded Weakly Bonded Interatomic Distance Shear Strain, Shear Stress, Shear Stress Shear Stress and Strain Shear Strain shear stress, = Shear Load / Area shear strain, = angle of deformation (radians) shear modulus, G = /(elastic region) Elastic Properties of Materials • Poisson’s ratio: When a metal is strained in one direction, there are corresponding strains in all other directions. • For a uniaxial tension strain, the lateral strains are constrictive. • Conversely, for a uniaxial compressive strain, the lateral strains are expansive. • i.e.; the lateral strains are opposite in sign to the axial strain. • The ratio of lateral to axial strains is known as Poisson’s ratio, n. Poisson’s Ratio, n ey ex n ez ez For most metals, 0.25 < n< 0.35 in the elastic range Furthermore: E 2G(1 n ) Plastic Deformation Elastic Plastic Elastic Plastic Sy Sy Elastic Plastic Stress Sy 0.002 Most Metals - Al, Cu 0.002 Strain Clad Al-Alloys 0.002 Low carbon Steel Microstructural Origins of Plasticity • Slip, Climb and Slide of atoms in the crystal structure. • Slip and Climb occur at Dislocations and Slide occurs at Grain Boundaries. Elastic and Plastic Strain P (e,S) e ee e p Stress S ee E e p e ee Total Strain Strain Plastic ep ee Elastic The 0.2% offset yield stress is the stress that gives a plastic (permanent) strain of 0.002. Elastic Recovery Loading Reloading Stress Loading Unloading Unloading Strain elastic strain Strain Ductility - EL% & AR% • Elongation EL% L f Lo Lo x 100 Lo Lf • Area Reduction AR% Ao A f Ao Ao x 100 Af Ductile Vs Brittle Materials Engineering Stress • Only Ductile materials will exhibit necking. • Ductile if EL%>8% (approximately) • Brittle if EL% < 5% (approximately) Engineering Strain Toughness & Resilience • Toughness: A measure of the ability of a material to absorb energy without fracture. (J/m3 or N.mm/mm3= MPa) • Resilience: A measure of the ability of a material to absorb energy without plastic or permanent deformation. (J/m3 or N.mm/mm3= MPa) • Note: Both are determined as energy/unit volume Engineering Stress, S=P/Ao Toughness, Ut Su Sy ef Ut S de o (S y Su ) EL% 100 2 Engineering Strain, e = L/Lo) Engineering Stress, S=P/Ao Resilience, Ur Su Sy ey Ur S de o E ey Sy e y 2 Sy 2 2E Engineering Strain, e = L/Lo) X Typical Mechanical Properties Metals in annealed (soft) condition Material 1040 Steel 1080 Steel 2024 Al Alloy 316 Stainless Steel 70/30 Brass 6-4 Ti Alloy AZ80 Mg Alloy Yield Stress (MPa) 350 380 100 210 75 942 285 Ultimate Stress (MPa) 520 615 200 550 300 1000 340 Ductility EL% 30 25 18 60 70 14 11 Elastic Modulus (MPa) 207000 207000 72000 195000 110000 107000 45000 Poisson’s Ratio 0.30 0.30 0.33 0.30 0.35 0.36 0.29