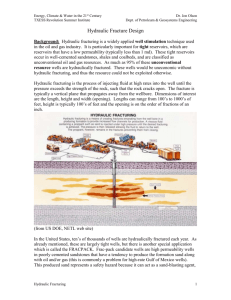

Computer simulation of hydraulic fractures

advertisement

MODELING OF HYDRAULIC FRACTURES 1 HYDRAULIC FRACTURES Hydraulic fracturing can be broadly defined as the process by which a fracture initiates and propagates due to hydraulic loading (i.e., pressure) applied by a fluid inside the fracture. Hydraulic fracturing is a complicated process to model, as it involves the coupling of at least three processes: (i) the mechanical deformation induced by the fluid pressure on the fracture surfaces; (ii) the flow of fluid within the fracture; (iii) the fracture propagation. 2 HYDRAULIC FRACTURES creation of an initial path for the fracture (‘‘perforation’’ - specially designed shaped-charges are blasted on the wellbore walls with given orientations, perforating the casing and creating finger-like holes or weak points in the hydrocarbon-laden formation) a viscous fluid is pumped inside the wellbore, inducing a steep rise in the pressure which eventually leads to the initiation of a fracture at the perforated interval. a ‘‘pad’’ of clean fluid is usually pumped first, to provide sufficient fracture width for the proppant that follows. proppant is injected at a later stage as a suspension or slurry. at the end of the treatment, when pumping stops, leak-off of the residual fracturing fluid into the porous reservoir allows the fracture surfaces to close onto the proppant pack under the action of the far-field compressive stresses. 3 POSSIBLE PROBLEMS prediction of fracture geometry effective prevention of crack closure optimal choice of fracturing fluid fluid leak-off avoid screenouts caused by proppant a bridging and holdup proppant flowback 4 MODEL ASSUMPTIONS the material of the reservoir is considered to be linearly elastic in the case of layered reservoir layers are parallel and perfectly paired the fracture occurs in the same vertical plane accepted model of Newtonian fluid One don’t need to take into account inelastic (plastic) behavior of the breed non-parallelism and imperfect conjugation of surface layers the real geometry of the crack natural fracturing the initial inhomogeneous stress fields caused, in particular, porosity patterns compressibility, plasticity, viscoelasticity of the fluid the impact of leakage on the pressure inside the cracks 5 KGD Model For the horizontal plane strain geometry, the fracture zone should deform independently of the upper and lower layers. This would occur for free slippage on these layers, or approximately represent a fracture with a horizontal penetration much smaller than the vertical one. The fracture shape should not depend on the vertical position. Such a geometry is shown in Fig. 3-5; it has a constant and uniform height and a rectangular cross section (Khristianovic and Zheltov, 1955; Geema and de Klerk, 1969-KGD Model). Crack opening is solved in the horizontal plane. 6 PKN Model A second situation exists when there is a large confinement, hence the fracture is limited to a given zone. Perkins and Kern (1961) and Nordgren (1972) considered the plane strain assumption in vertical planes, so each vertical cross section deforms independently of the others (PKN Model). However, the fracture widths in vertical planes are coupled through the fluid-flow and continuity equations. Since there is no vertical extension (or fluid flow) in each vertical section, the pressure is uniform.This case would approximate a fracture with a horizontal penetration much larger than the vertical penetration. Crack opening is solved in the vertical plane. 7 REFERENCES Adachi J., Siebrits E., Peirce A., Desroches J. Computer simulation of hydraulic fractures // Int. J. of Rock Mechanics & Mining Sciences, 44, 2007 Michael. J. Economides, Kenneth G. Nolte Reservoir Stimulation 8 Thank you for your attention! 9