are piezoelectric constants

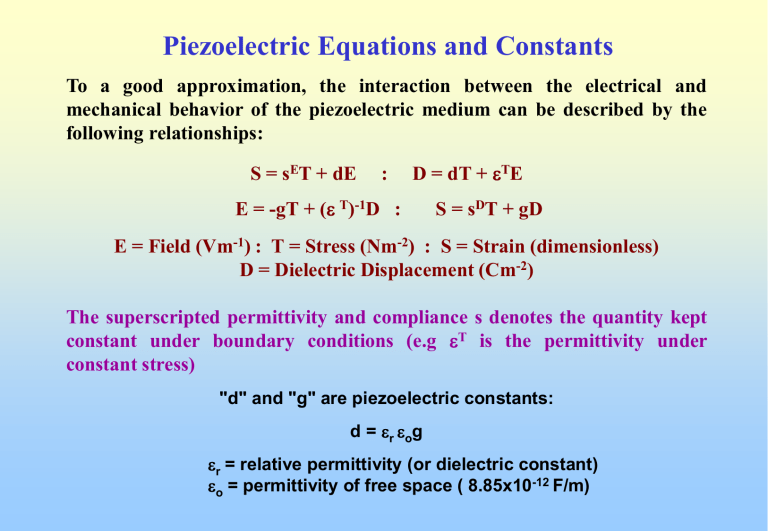

Piezoelectric Equations and Constants

To a good approximation, the interaction between the electrical and mechanical behavior of the piezoelectric medium can be described by the following relationships:

S = s E T + dE : D = dT +

T E

E = -gT + (

T ) -1 D : S = s D T + gD

E = Field (Vm -1 ) : T = Stress (Nm -2 ) : S = Strain (dimensionless)

D = Dielectric Displacement (Cm -2 )

The superscripted permittivity and compliance s denotes the quantity kept constant under boundary conditions (e.g

T is the permittivity under constant stress)

"d" and "g" are piezoelectric constants: d =

r

o g

r

o

= relative permittivity (or dielectric constant)

= permittivity of free space ( 8.85x10

-12 F/m)

Piezoelectric Equations and Constants

Directional Dependence

Because poled piezoelectric ceramics are anisotropic and the direction of polarizing may be freely chosen, a method of identifying the axes of a component is necessary in order to specify its parameters.

The direction of polarization is conventionally taken as the 3 axis, with axes 1 and 2 perpendicular to this. The terms 4, 5 and 6 refer to shear stains associated with the 1, 2 and 3 directions.

Piezoelectric Equations and Constants

Piezoelectric Charge Constant (d)

The polarization generated per unit of mechanical stress applied to a piezoelectric material alternatively

The mechanical strain experienced by a piezoelectric material per unit of electric field applied

The first subscript indicates the direction of polarization generated in the material when the electric field, E, is zero or, alternatively, is the direction of the applied field strength.

The second subscript is the direction of the applied stress or the induced strain, respectively.

d is an important indicator of a material's suitability for strain-dependent

(actuator) applications.

Piezoelectric Equations and Constants d

33

induced polarization in direction 3 (parallel to direction in which ceramic element is polarized) per unit stress applied in direction 3 or induced strain in direction 3 per unit electric field applied in direction 3 d

31

induced polarization in direction 3 (parallel to direction in which ceramic element is polarized) per unit stress applied in direction 1

(perpendicular to direction in which ceramic element is polarized) or induced strain in direction 1 per unit electric field applied in direction 3 d

15

induced polarization in direction 1 (perpendicular to direction in which ceramic element is polarized) per unit shear stress applied about direction 2 (direction 2 perpendicular to direction in which ceramic element is polarized) or induced shear strain about direction 2 per unit electric field applied in direction 1

Piezoelectric Equations and Constants

Piezoelectric Voltage Constant (g)

The electric field generated by a piezoelectric material per unit of mechanical stress applied alternatively

The mechanical strain experienced by a piezoelectric material per unit of electric displacement applied.

The first subscript to g indicates the direction of the electric field generated in the material, or the direction of the applied electric displacement.

The second subscript is the direction of the applied stress or the induced strain, respectively.

g is important for assessing a material's suitability for sensing (sensor) applications.

Piezoelectric Equations and Constants g

33

induced electric field in direction 3 (parallel to direction in which ceramic element is polarized) per unit stress applied in direction 3 or induced strain in direction 3 per unit electric displacement applied in direction 3 g

31

induced electric field in direction 3 (parallel to direction in which ceramic element is polarized) per unit stress applied in direction 1 (perpendicular to direction in which ceramic element is polarized) or induced strain in direction 1 per unit electric displacement applied in direction 3 g

15

induced electric field in direction 1 (perpendicular to direction in which ceramic element is polarized) per unit shear stress applied about direction 2

(direction 2 perpendicular to direction in which ceramic element is polarized) or induced shear strain about direction 2 per unit electric displacement applied in direction 1

Constant d g

Definition of the Constants d and g

Definition dielectric displacement developed applied mechanical stress

(E = constant)

S.I. Units coulomb/meter 2

Pa

C/N strain developed applied field

(T = constant) field developed applied mechanical stress

(D = constant) meter/meter volt/meter volt/meter

Pa m/V

Vm/N strain developed applied dielectric displacement

(T = constant) meter/meter coulomb/meter 2 m 2 /C

Piezoelectric Equations and Constants

There are other parameters to be considered which characterize a piezoelectric material; of prime importance are the coupling coefficient, loss factor, the mechanical quality factor, and the dielectric permittivity.

The Electromechanical Coupling Coefficient (k)

This parameter determines the efficiency of energy conversion in the component (but not the overall efficiency of the ceramic as a transducer) and is defined as follows:

(i) For an electrically stressed component k 2 = stored mechanical energy total stored energy

(ii) For a mechanically stressed component k 2 = stored electrical energy total stored energy

Piezoelectric Equations and Constants

The electromechanical coupling factor (k)

An indicator of the effectiveness with which a piezoelectric material converts electrical energy into mechanical energy, or converts mechanical energy into electrical energy

The first subscript to k denotes the direction along which the electrodes are applied

The second denotes the direction along which the mechanical energy is applied, or developed

Modes of Vibration

Modes of Vibration

Modes of Vibration

Piezoelectric Parameters and Measurements

The direct and converse effects d constant

D = dX +

T E

Direct Effect

S = s D X + dE

Converse Effect

S = elastic compliance

Ferroelectric ceramics have non-linear properties

D = d

X +

T

E

x = s E

X + d

E

These coefficients are not all independent d ij

/ g ij e ij

/ h ij

ii x

ii x

(D =ex and E = hx)

Piezoelectric Parameters and Measurements

Elastic behavior can be expressed in terms of s ij

= elastic compliance c ij

= elastic stiffness c ij

S ij

For poled ceramics s jk

= s kj and c jk

= c kj

Only six terms are needed s

11

, s

12

, s

13

, s

33

, s

44

, s

66 s ij

E : c ij

E

or c

11

, c

12

, c

13

, c

33

, c

44

, c

66

Short circuit s D ij

: c ij

D

Open circuit

12

The Poisson ratio

s E

12 s

11

E

;

13

s

13

E s

33

E

Piezoelectric Parameters and Measurements

The values of the piezoelectric properties

Derived from resonance behavior

Suitably Shaped Specimens

The resonance behavior is represented by an equivalent circuit

Piezoelectric Parameters and Measurements f r and f a

: resonant and anti-resonant frequencies when reactance (X e

) is zero f s

: frequency at which the series arm has zero reactance (X

1

= 0) f p

: frequency when resistive component R e is maximum f m and f n

: frequencies for the minimum and maximum impedance Z

Piezoelectric Parameters and Measurements

An important parameter for piezoelectric specimen

The effective electromechanical coupling coefficient k eff

k eff is related to c

0

, c

1 and f p

, f s

, f a

, f r

, f m

, and f n k eff

2

c

0 c

1

c

1

f p

2

f p

2 f s

2

f a

2

f a

2 f r

2

f n

2

f n

2 f m

2

Values for f n and f m are measured by a suitable bridge

(approximation is good if Q of the resonator > 100)

d and g coefficients can be determined from k

Piezoelectric Parameters and Measurements

For a piezoceramic rod ( 6 mm in diameter and 15 mm long)

Poled along its length and electroded both ends

For resonance condition k

33

2 f s f p tan

2 f p

f p f s

Dielectric Permittivity

x

33 can be determined from capacitance C at a frequency well below resonance

x

33

c

A

A = cross-sectional area of the rod

l = length of the rod

Piezoelectric Parameters and Measurements s D

33 p

1

D s

33

4

f p

2 l 2

= density

Superscript D = Open-circuit = constant electric displacement s

33

E d

33

1

s

33

D k

33

2 k

33

X

33 s

33

E

1

2

g

33

X

33

d

33

X

33

33

X ( 1

k

33

2 )

Piezoelectric Parameters and Measurements

For a twin disc of diameter d

Considering a radial mode resonance k p

2

1

k p

2

f

J

0

, J

1

,

f p

f s f s

J

0

, J

1 are Bessel functions and

is Poisson’s radio

Curve is very insensitive for

of common piezoceramic 0.28 <

< 0.32

Piezoelectric Parameters and Measurements

2 k

31

1 s

E

11

1

2

2 d

2 k p

2 f

2

( 1 s

1

2

2

)

(

~ 2 ) d

31

k

31

(

X

33

S

E

11

)

1

2 g

31

d

31

X

33

If minimum impedance |Z m

| at resonance is known

1

Q m

4

f Z m

( c

0

c )

Dielectric Q factor = 1/tan

Piezoelectric Parameters and Measurements

Piezoelectric Parameters and Measurements

IRE Standards Measurements on Piezoelectric Ceramics (IRE 1961) f r

= Resonant Frequency = frequency at minimum impedance f a

= Anti-resonant Frequency = frequency at maximum impedance

Ferroelectric Hysteresis

Sawyer-Tower Circuit

Hysteresis Loop of PZT

Hysteresis Loop

Procedures for Measurement Properties of

Piezoelectric Ceramics

Constants to be measured

Coupling Factors: k

33 k

31 k p

Free Relative Dielectric Constant : K

3

T

Dissipation Factor: D

Elastic-Compliances: D

S

33

E

S

33

D

S

11

E

S

11

Piezoelectric d and g constants: d

33 g

33 d

31 g

31

Mechanical Factor: Q m

Test Specimens

Different shapes are required for different constants

Measurement Properties of Piezoelectric Ceramics

Test Specimens : Different shapes are required for different constants

Equipment for Simple Measurements

The measurements to be performed on the specimen

1.

weight or density

2.

physical dimensions

3.

free capacitance and dissipation factor

4.

frequencies of minimum impedance and maximum impedance

5.

The magnitude of the minimum impedance

Equipment required to measure the data

Balance, Micrometer, Capacitance Bridge (capable of 10 pF-10,000 pF)

Oscillator (up to 200 kHz), Frequency counter,

Sensitive electronic voltmeter (200 KHz), variable resistor

Determination of Frequency and Impedance f m

= Meter Peak at the the frequency at minimum impedance f n

= Meter Null at the frequency at maximum impedance

Z m

= The magnitude resistance at the frequency of minimum impedance

Calculation of Constants

Calculation of Coupling k

33

(Applicable for Length Poled Rod)

Calculation of Coupling k

31

(Applicable for Long, Slim, Thickness Poled Specimen)

Calculation of Constants

Calculation of Coupling k p

(Applicable for Thin Discs)

Determine k p from curve (only for ceramic with Poisson’s Ratio ~ 0.3

BT and PZT have Poisson’s Ration ~ 0.3

Calculation of Constants

Calculation of Elastic Constant s D

33

(Applicable for Length Poled Rod)

Calculation of Elastic Constant s E

33

Calculation of Elastic Constant s E

11

(Applicable for Long, Slim, Thickness Poled Specimens)

Calculation of Constants

Calculation of Elastic Constant s D

11

Calculation of Piezoelectric Constant d

33

Calculation of Piezoelectric Constant d

33

Calculation of Constants

Calculation of Piezoelectric Constant g

33

Calculation of Piezoelectric Constant g

11

Calculation of Mechanical Q