Firearms Examiner

advertisement

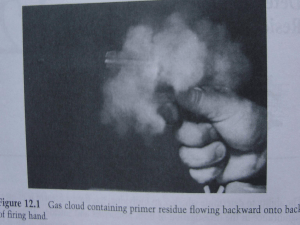

Syracuse University June, 2010 Firearms and Toolmarks Forensic Firearm Analysis WALLIE HOWARD JR. CENTER FOR FORENSIC SCIENCES Matthew Kurimsky Firearms Examiner FORENSIC FIREARMS IDENTIFICATION • A scientific process of determining whether a bullet or cartridge case was fired from a particular weapon. This is done by examining and evaluating the class and individual characteristics imparted onto the bullet or cartridge case. FIREARMS SECTION • • • • • • • FIREARM IDENTIFICATION OPERABILITY ANALYSIS FIREARM COMPARISONS PHYSICAL MATCH COMPARISONS IBIS ENTRIES SERIAL NUMBER RESTORATION GUNSHOT RESIDUE DISTANCE DETERMINATION FIREARMS IDENTIFICATION • Can determine the general condition of a firearm and whether the firearm is mechanically functional. • Can determine whether the firearm was altered to fire in full-automatic mode. • Can be test fired to obtain known specimens for comparison to evidence ammunition components. HOMEMADE CLASS CHARACTERISTICS • Are measurable features of a specimen that indicate a restricted group source. • Result from design factors, and are determined prior to manufacture. • Examples are firing pin shape, caliber, and general rifling characteristics. BREECH FACE Breech face of a firearm. Arch breech face marks. RIFLING • Helical grooves in the bore of a firearm barrel to impart rotary motion to a projectile. Rifling COMMON TYPES OF RIFLING • BROACH RIFLING: Cuts the grooves by being pushed or pulled through the barrel while being rotated. • BUTTON RIFLING: Pushed or pulled through a drilled and reamed barrel so as to cold form the spiral grooves to the desired depth and twist. NOT a cutting process. GENERAL RIFLING CHARACTERISTICS • The number, width and direction of twist of the rifling grooves in a barrel of a given caliber firearm. INDIVIDUAL CHARACTERISTICS • Marks produced by the random imperfections or irregularities of tool surfaces. • These random imperfections or irregularities are produced incidental to manufacture and/or caused by use, corrosion, or damage. • They are unique to that tool and distinguish it from all other tools. COMPARISON MICROSCOPE • Optically bridged so objects can be viewed side by side. CARTRIDGE CASE OR SHOTSHELL EXAMINATION • Cartridge case examination can determine the caliber or gauge, and the manufacturer. • The images of questioned cartridge cases can be entered into IBIS to compare with evidence from other shooting incidents. • The microscopic characteristics of evidence cartridge cases can be examined to determine whether they were fired in a specific firearm. CARTRIDGE CASING IDENTIFICATION Parallel breech face marks. Granular breech face marks. Circular breech face marks. FIRING PIN Firing pin impression. Firing pin drag mark. OTHER MARKS Ejector marks. Extractor marks. BULLET EXAMINATIONS • Bullets can be examined to determine the general rifling characteristics. • The microscopic characteristics on evidence bullets can be compared to test-fired bullets from a suspect firearm to determine whether the evidence bullet was fired from that firearm. SHOOTING TANK Bullet comparisons The gun barrel is produced from a solid bar of steel that has been hollowed out by drilling The microscopic drill marks left on the barrel inner surface are randomly irregular and would in themselves serve to impart a uniqueness to each barrel. Manufacturers make the inner surface of the barrel with spiral groves, a step known as rifling Bullet comparisons Why rifling in a barrel? Prevents the bullet from tumbling when it leaves the barrel, more accuracy. Bullet comparisons The diameter of the gun barrel is measured between opposite lands, this is known as the caliber of the weapon. It is usually expressed in hundredths of an inch (.22) or millimeters (9mm) Caliber - the diameter of the bore of a rifled firearm. Bullet comparisons Every firearms manufacturer chooses a rifling process that is best suited to meet the production standards and requirements of its product. Once the choice is made, the class characteristics of the weapons barrel will remain consistent; each will have the same number of lands and grooves, the same approximate width and directions of twist. Bullet comparisons Ex: .32 caliber Smith & Wesson revolvers have five lands and grooves twisting to the right Ex: .32 caliber Colt revolvers exhibit six lands and grooves twisting to the left Bullet comparisons There are fine lines or striations, many running the length of the barrel’s lands and grooves. These are caused by minute imperfections found on the rifling cutter’s surface or they are produced by minute chips of steel pushed against the barrel’s inner surface. The fact is that the random distribution and irregularities of these markings are impossible to duplicate exactly in any two barrels. Bullet comparisons No two rifled barrels, even those manufactured in succession, will have identical striation markings! These striations form the individual characteristics of the barrel. The number of lands and grooves, and their direction of twist are obvious points of comparison during initial stages of the examination Bullet comparisons By comparing the lands and grooves and directions of twist, we can eliminate certain weapons. The most important tool for the firearms examiner is the comparison microscope. COMARISON MICROSCOPE Bullet comparisons The striations of the bullet are lined up and compared BULLET IDENTIFICATION Bullet comparisons With shotguns, most barrels are smooth The diameter of the shotgun barrel is expressed by the term gauge Gauge - the number of lead balls with the same diameter as the barrel that would make a pound ex: 20 ga = diameter of lead ball weighing 1/20th of a pound Exception to this is 410 gauge, actually is .410 inch diameter PHYSICAL MATCH COMPARISON • Physical match comparison can determine whether evidence was joined together and subsequently broken apart. Projectile jacket separation. Copper jacket fragment. MATCH Fragment match. Stria match. INTEGRATED BALLISTICS IDENTIFICATION SYSTEM (IBIS) • Images of projectiles and cartridge casings recovered from the crime scene, or produced from evidence weapons are entered into the database and searched. • Used to link multiple crimes to a single weapon. • Potential hits are compared to one another by a firearms examiner on a comparison microscope. • Hits are NOT made by simply looking at the images in IBIS. SHOT PELLETS, BUCK SHOT, OR SLUGS • Examination of shot pellets, buck shot, or slugs can determine the size of the shot or the gauge of the slug, and the manufacturer. SHOTSHELL COMPONENTS 00 BUCK WADDING EXAMINATIONS • Examinations of wadding components can determine the gauge and the manufacturer. UNFIRED CARTRIDGES OR SHOTSHELLS • Examinations of unfired cartridges or shotshells can determine the caliber or gauge and whether there are marks of value for comparison. • Examinations can also determine whether the ammunition was loaded into and extracted from a specific firearm. • Unfired and fired cartridges or shotshells can be associated through manufacturing marks. SERIAL NUMBER RESTORATIONS • Obliterated and/or altered firearm serial numbers can sometimes be restored. • Chemical, electrolytic, and magnetic particle inspection are some of the methods used. Before restoration. After restoration. FIRING RANGE Gunpowder residues The accuracy of a distance determination varies according to the circumstances of the case Because the spread and density of the residue pattern will vary widely between weapons and ammunition. Gunpowder residues A COMPARISON IS SIGNIFICANT ONLY WHEN IT IS MADE WITH THE SUSPECT WEAPON AND AMMUNITION OR AMMUNITION OF THE SAME MAKE AND TYPE Contact Pattern Shotgun Gunpowder residues Items that influence estimating target distance (amt. Of gunpowder residue) Barrel length Caliber type of ammunition Type and condition of the weapon fired Gunpowder residues Tests done on garments in the lab Examine microscopically for presence of gunpowder residue Nitrite test - greis test Sodium rhodizoante test (lead) Greis test - a chemical test to develop patterns of gun powder residues around bullet holes Victims Clothing 3 inch Test Pattern DISTANCE DETERMINATION SODIUM RHODIZONATE TEST • Tests for the presence of lead. • Converts lead to lead rhodizonate. GRIESS TEST • Tests for the presence of nitrites. • Converts nitrites to nitrates. PRIMER RESIDUE ON HANDS GSR During the firing process. GSR particle. Toolmarks Defined as any impression, cut, gouge, or abrasion caused by a tool coming into contact with another object USUALLY THERE WILL BE CLASS CHARACTERISTICS SIZE SHAPE Toolmarks Sometimes nicks and wear patterns will individualize a tool INDIVIDUAL CHARACTERISTICS ARE HARD TO IDENTIFY BECAUSE OF THE DIFFICULTY OF DUPLICATING THE TOOL MARK IN THE LAB Toolmarks Toolmarks UNDER NO CIRCUMSTANCE MUST THE CRIME SCENE INVESTIGATOR ATTEMPT TO FIT THE SUSPECT TOOL INTO THE TOOL MARK Toolmarks BEAR IN MIND THAT THE TOOL OR IMPRESSION MAY CONTAIN VALUABLE TRACE EVIDENCE QUESTIONS? Matthew Kurimsky – Firearms Examiner matthewkurimsky@ongov.net 315-435-3800 firearms unit