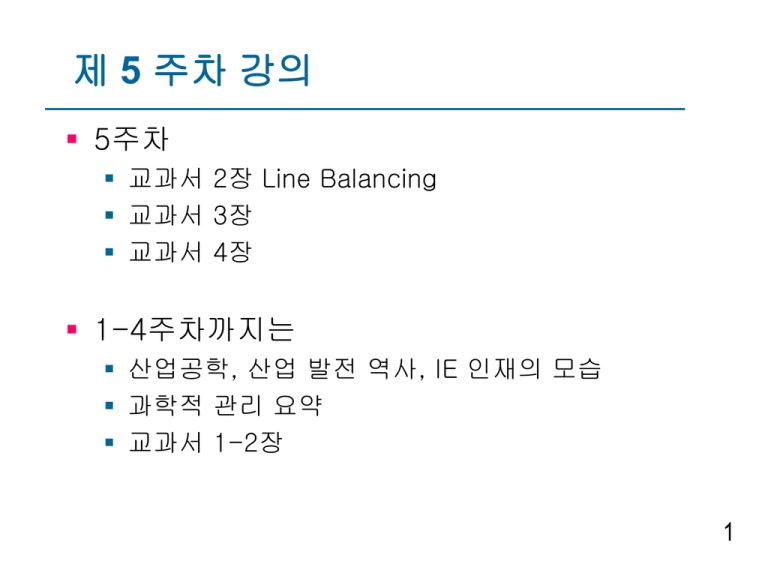

제 5 주차 강의 - mailab.snu.ac.kr

advertisement

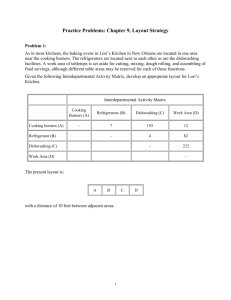

제 5 주차 강의 5주차 교과서 2장 Line Balancing 교과서 3장 교과서 4장 1-4주차까지는 산업공학, 산업 발전 역사, IE 인재의 모습 과학적 관리 요약 교과서 1-2장 1 교재 Chapter Chapter Chapter Chapter Chapter Chapter Chapter Chapter Chapter Chapter Chapter Chapter Chapter Chapter Chapter Chapter 3 Operation Analysis 4 Manual Work Design 5 Workplace, Equipment and Tool Design 6 Work Environment Design 7 Cognitive Work Design 8 Workplace and System Safety 9 Implementation 10 Time Study 11 Performance Rating and Allowances 12 Standard Data 13 Predetermined Time Systems 14 Work Sampling 15 Indirect and Expense Work 16 Standard Follow-up 17 Wage Payment 18 Training and Management Practice 2 Motion Study 작업방법(3M+IE,환경-Layout, …) 설계 크게는 Operation Analysis(넓게) Motion Study(중간, 육안) Micro/Memo Motion Study(세밀하게, 카메라 사용) 로 구분 Chart 와 Diagram Flow Process Chart, Flow Diagram Fish Bone Diagram, Pareto Chart, Operation/Operator(L/R) Process Chart, Gang Process Chart, Network Diagram(PERT, CPM Chart), 등 3 Methods, Standards, and Work Design 12th Edition Niebel/Freivalds Copyright © The McGraw-Hill Companies, Inc. Permission required for reproduction or display. 개선 체크 리스트 1. 2. 3. 4. 5. 6. 7. 8. 9. Operation Purpose Part Design Tolerance and Specifications Material Manufacturing Sequence and Process Setup and Tools Material Handling Plant Layout Work Design 5 1. Operation Purpose 3정 5S 황삭, 정삭 Spray Paint를 위한 jig 설계 대형 치차 가공 – 일교차, 온도차 고려 베어링 구입 후 조립 vs 셋트 구입 C&H Sugar Co. 의 사례 6 2. Part Design 부품의 수를 줄이라, DfX DfM, DfA, … 서류양식의 디자인 Drawing Stress Material: Fatigue Failure, Creeping 7 제품설계 그리고 정확한 정보가 중요하다 3. Tolerance and Specifications 1.설계 차이: Drilling vs. EDM 2. Reaming 3. Shrink fit 4. Inspection: Spot, Lot by Lot Sampling, 100% 5. Cost considerations 9 4. Material 10 Material Value Engingeering(2차세계대전 중) 기능/가격 = 가치 Finding better material Cost Function: (SS clad on Al.) Easier to process Nano-material (Graphene) 11 5. Manufacturing Sequence and Process Chip hauler, floor sweeper, Grind-DrillDeburr, Screw machine, 절삭유 12 6. Setup and Tools Group Technology: 설계 및 제조 Part Classification and Coding GT Layout Lehigh 대학 Mikell Groover 교수 자료 13 설계: Opitz code 제조: GT 분류 7. Material Handling 16 Material Handling: •The best handled part is the least handled part •10 Principles of Material Handling: Unit Load, Terminal Time, Mechanization, Automation, … •병원: Williamson Turn Stand, Hoyer-type Lift,… •104쪽의 Fork Lift Truck 분석 : 회전거리, 반경 등 8. Plant Layout Process(Functional) Layout versus Production(straight-line) Layout R. Muther교수의 SLP(Systematic Layout Planning) Lehigh 대학 Mikell Groover 교수 자료 19 From –To (Travel ) Chart Relationship Chart A: Absolutely necessary E: Especially important I: Important O: Ordinary U: Unimportant X: Not desirable 사무실 Layout 사례 대안 ( Alternatives) 간의 비교 Computer Aided Layout •CRAFT •CORELAP •ALDEP •SPIRAL •FactoryPLAN, FactoryFLOW 9. Work Design 26 Check list