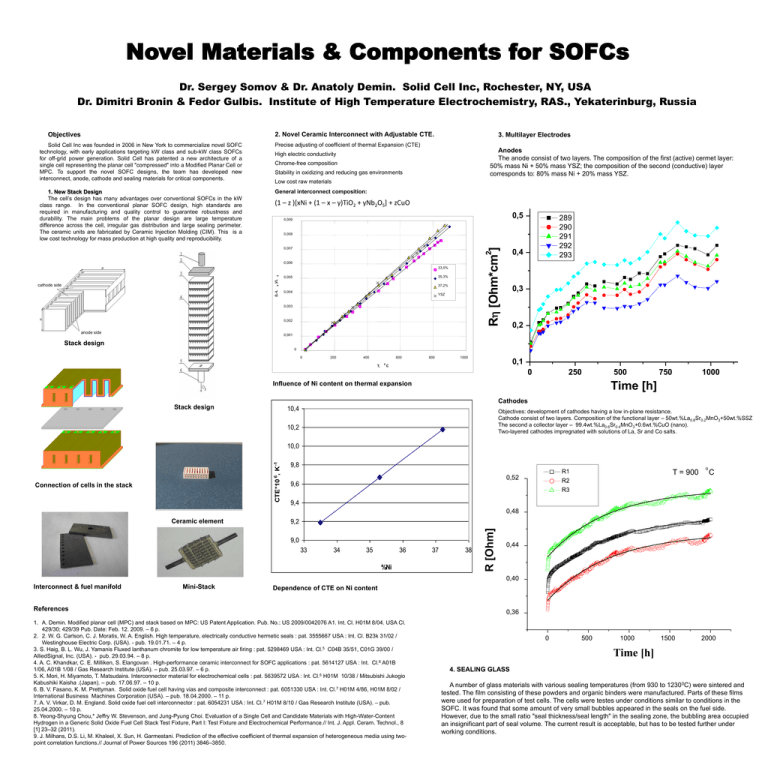

Novel Materials & Components for SOFCs

advertisement

Novel Materials & Components for SOFCs Dr. Sergey Somov & Dr. Anatoly Demin. Solid Cell Inc, Rochester, NY, USA Dr. Dimitri Bronin & Fedor Gulbis. Institute of High Temperature Electrochemistry, RAS., Yekaterinburg, Russia 2. Novel Ceramic Interconnect with Adjustable CTE. Objectives Solid Cell Inc was founded in 2006 in New York to commercialize novel SOFC technology, with early applications targeting kW class and sub-kW class SOFCs for off-grid power generation. Solid Cell has patented a new architecture of a single cell representing the planar cell "compressed" into a Modified Planar Cell or MPC. To support the novel SOFC designs, the team has developed new interconnect, anode, cathode and sealing materials for critical components. Precise adjusting of coefficient of thermal Expansion (CTE) 1. New Stack Design The cell’s design has many advantages over conventional SOFCs in the kW class range. In the conventional planar SOFC design, high standards are required in manufacturing and quality control to guarantee robustness and durability. The main problems of the planar design are large temperature difference across the cell, irregular gas distribution and large sealing perimeter. The ceramic units are fabricated by Ceramic Injection Molding (CIM). This is a low cost technology for mass production at high quality and reproducibility. General interconnect composition: 3. Multilayer Electrodes Anodes The anode consist of two layers. The composition of the first (active) cermet layer: 50% mass Ni + 50% mass YSZ; the composition of the second (conductive) layer corresponds to: 80% mass Ni + 20% mass YSZ. High electric conductivity Chrome-free composition Stability in oxidizing and reducing gas environments Low cost raw materials (1 – z )[xNi + (1 – x – y)TiO2 + yNb2O5] + zCuO 0,5 0,009 0,008 R [Ohm*cm ] 0,007 0,4 2 0,006 35,3% 0,005 )/L 0 33,5% 37,2% (L-L 0 cathode side 289 290 291 292 293 0,004 YSZ 0,003 0,002 anode side 0,3 0,2 0,001 Stack design 0 0 200 400 600 Т, 0 800 1000 0,1 С 0 250 Influence of Ni content on thermal expansion 500 750 1000 Time [h] Cathodes Stack design 10,4 Objectives: development of cathodes having a low in-plane resistance. Cathode consist of two layers. Composition of the functional layer – 50wt.%La0.8Sr0.2MnO3+50wt.%SSZ The second a collector layer – 99.4wt.%La0.6Sr0.4MnO3+0.6wt.%CuO (nano). Two-layered cathodes impregnated with solutions of La, Sr and Co salts. 10,2 CTE*10 6, K -1 10,0 Connection of cells in the stack 9,8 R1 0,52 9,6 T = 900 o C R2 R3 9,4 0,48 9,2 9,0 33 34 35 36 %Ni 37 38 R [Ohm] Ceramic element 0,44 0,40 Interconnect & fuel manifold Mini-Stack Dependence of CTE on Ni content References 1. A. Demin. Modified planar cell (MPC) and stack based on MPC: US Patent Application. Pub. No.: US 2009/0042076 A1. Int. Cl. H01M 8/04. USA Cl. 429/30; 429/39 Pub. Date: Feb. 12. 2009. – 6 p. 2. 2. W. G. Carlson, C. J. Moratis, W. A. English. High temperature, electrically conductive hermetic seals : pat. 3555667 USA : Int. Cl. B23k 31/02 / Westinghouse Electric Corp. (USA). - pub. 19.01.71. – 4 p. 3. S. Haig, B. L. Wu, J. Yamanis Fluxed lanthanum chromite for low temperature air firing : pat. 5298469 USA : Int. Cl.5 C04B 35/51, C01G 39/00 / AlliedSignal, Inc. (USA). - pub. 29.03.94. – 8 p. 4. A. C. Khandkar, C. E. Milliken, S. Elangovan . High-performance ceramic interconnect for SOFC applications : pat. 5614127 USA : Int. Cl.6 A01B 1/06, A01B 1/08 / Gas Research Institute (USA). – pub. 25.03.97. – 6 p. 5. K. Mori, H. Miyamoto, T. Matsudaira. Interconnector material for electrochemical cells : pat. 5639572 USA : Int. Cl.6 H01M 10/38 / Mitsubishi Jukogio Kabushiki Kaisha .(Japan). – pub. 17.06.97. – 10 p. 6. B. V. Fasano, K. M. Prettyman. Solid oxide fuel cell having vias and composite interconnect : pat. 6051330 USA : Int. Cl.7 H01M 4/86, H01M 8/02 / International Business Machines Corporation (USA). – pub. 18.04.2000. – 11 p. 7. A. V. Virkar, D. M. England. Solid oxide fuel cell interconnector : pat. 6054231 USA : Int. Cl.7 H01M 8/10 / Gas Research Institute (USA). – pub. 25.04.2000. – 10 p. 8. Yeong-Shyung Chou,* Jeffry W. Stevenson, and Jung-Pyung Choi. Evaluation of a Single Cell and Candidate Materials with High-Water-Content Hydrogen in a Generic Solid Oxide Fuel Cell Stack Test Fixture, Part I: Test Fixture and Electrochemical Performance.// Int. J. Appl. Ceram. Technol., 8 [1] 23–32 (2011). 9. J. Milhans, D.S. Li, M. Khaleel, X. Sun, H. Garmestani. Prediction of the effective coefficient of thermal expansion of heterogeneous media using twopoint correlation functions.// Journal of Power Sources 196 (2011) 3846–3850. 0,36 0 500 1000 1500 2000 Time [h] 4. SEALING GLASS A number of glass materials with various sealing temperatures (from 930 to 1230 0C) were sintered and tested. The film consisting of these powders and organic binders were manufactured. Parts of these films were used for preparation of test cells. The cells were testes under conditions similar to conditions in the SOFC. It was found that some amount of very small bubbles appeared in the seals on the fuel side. However, due to the small ratio "seal thickness/seal length" in the sealing zone, the bubbling area occupied an insignificant part of seal volume. The current result is acceptable, but has to be tested further under working conditions.

![Wrapping Machine [VP] OPP film wrapping for flat](http://s2.studylib.net/store/data/005550216_1-6280112292e4337f148ac93f5e8746a4-300x300.png)