Long failure-prone production lines

advertisement

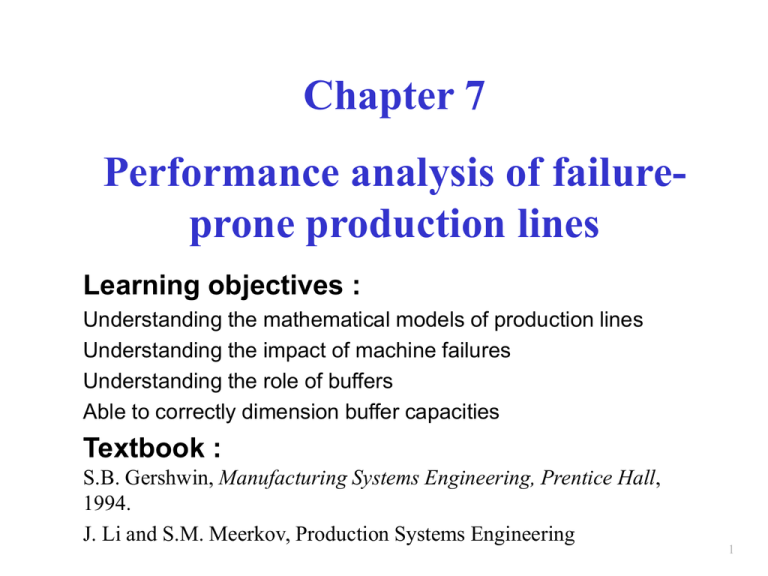

Chapter 7

Performance analysis of failureprone production lines

Learning objectives :

Understanding the mathematical models of production lines

Understanding the impact of machine failures

Understanding the role of buffers

Able to correctly dimension buffer capacities

Textbook :

S.B. Gershwin, Manufacturing Systems Engineering, Prentice Hall,

1994.

J. Li and S.M. Meerkov, Production Systems Engineering

1

Plan

• Basic concepts

• Failure-prone single-machine systems

• Production lines with unlimited buffers

• Production lines without buffers

• Aggregation of parallel machines and consecutive

dependent machines

• Two-machine production lines with intermediate buffer

• Long failure-prone production lines

2

Basic concepts

3

Production lines or tranfer lines

M1

B1

M2

B2

machine

M3

B3

M4

Buffer

Frequent production disruption by machine failures

Buffers are of finite capacity

Production often varies wildly

4

Production lines or tranfer lines

5

Production capability of a machine

Cycle time or processing time (t) :

• time necessary to process a part by a machine

• Constant cycle times (large assembly systems)

• Variable or random cycle time (job-shop environment).

Maximal production rate or max. capacity (U) :

• U = 1/t (parts per time unit)

6

Machine reliability model

• TBF = Time Between Failure (Tup)

• TTR = Time To Repair (Tdown)

• MTBF = Mean TBF

• MTTR = Mean TTR

• Failure rate l = 1/MTBF

• Repair rate m = 1/MTTR

l

UP

DOWN

m

7

Models of machine failures

ODF – Operation-Dependent Failure: the state of the

machine degrades ony when it produces.

Implication : an ODF cannot fail when it is not producing.

TDF – Time-Dependent Failure: the state of the

machine degrades all the time even if it is not producing.

Implication : a TDF machine can fail even if it is not

producing.

8

Models of machine failures

Cause of failures:

ODF: tool wear

TDF: electricity supply, electronic components, …

ODF failures account for 80% of disruptions in

manufacturing systems (Hanifin & Buzacott)

In this chapter, we mainly focus on ODF failures.

Example of a two machine production line to explain the

difference

9

Mathematical models of buffers

Buffer capacity : N

State of a buffer : number of parts in it varying from 0 to N

Assumptions:

• A part, produced by a machine, is immediately placed in

the downstream buffer, if it is not full.

• A part is immediately available for processing by a

machine, if the upstream buffer is not empty.

10

Mathematical models of buffers

Buffering capacity of a moving convey

l

v

Ttravel

N0

t

N K N0

Ttravel

where

l = length of the convey

v = speed of the convey

K = maximum number of carriers in the convey

11

Interaction between machines and buffers

Blocking Before Service (BBS):

A machine cannot operate and is blocked if

• it is up

• its downstream buffer is full

• no part can be removed from that buffer

Blocking After Service (BAS):

• A machine continue to produce even if the downstream buffer is full.

• The machine is blocked at the completion of the part if the buffer remains

full.

Buffer capacity convetion: NBBS = NBAS +1

Starvation : an idle up machine is starved if its upstream buffer is empty/

12

Performance measures

Throughput rate also called productivity (TH):

• Number of parts produced per time unit.

Production rate (PR):

• Number of parts produced per cycle time.

• Concept appropriate for synchronuous production systems with

all machines having identical cycle times

TH = U×PR

13

Performance measures

Work-in-process of the i-th buffer (WIPi)

• Average number of parts contained in the i-th buffer.

Total work-in-process (WIP):

• Average number of parts) in the system

• WIP = WIP1 + WIP2 + ...

Probability of blocking (BLi)

Probability of starvation (STi)

14

Failure-prone single-machine

systems

15

Throughput rate

MTBF

m

TH U

U

MTBF MTTR

lm

Proof:

•Average length of an UP period = MTBF

•Average length of a DOWN period = MTTR

•Production of an UP period = U. MTBF

•Length of an UP-DOWN cycle = MTBF + MTTR

•Throughput rate : TH = (U.MTBF) / (MTBF + MTTR).

UP

DOWN

16

A machine operating at a reduced speed U' < U

Operation Dependent Failure case

TH U '

m

U'

l

m

U

Time Dependent Failure case:

TH U '

m

lm

17

Production lines with unlimited

buffers

18

Assumptions

M1

B1

M2

B2

M3

B3

M4

• The first machine M1 is never starved

• The last machine is never blocked

• Each machine produces if its upstream buffer is not empty

19

Bottleneck machine

M1

B1

M2

B2

M3

B3

M4

A machine Mi is said to be a bottleneck if it proper

productivity (or isolated productivity) is smaller than

that of other machines, i.e.

Ui

mi

li mi

Uj

mj

lj m j

, j i

20

Throughput rate

M1

B1

M2

B2

M3

B3

M4

The throughput rate of a production line with unlimited buffers

is equal to that of the bottleneck machines, i.e. (Why?)

TH MIN

i

U i MTBFi

Um

MIN i i

i

MTBFi MTTRi

li mi

The throughput rate of a machine Mi is equal to that of the

slowest upstream machine, i.e.

TH j MIN

i j

U i MTBFi

Um

MIN i i

i j li mi

MTBFi MTTRi

21

Case of a single bottleneck machine

M1

B1

M2

B2

B3

M3

M4

The level of the input buffer of the bottleck machine grows

without limit (at which slope?)

All downstream buffers remain limited.

B2

B3

22

Case of two bottleneck machines

M1

B1

M2

B2

B3

M3

M4

The level of the input buffer of each bottleneck machines grows

without limit.

All other buffers downstream of the first bottleneck remain

limited.

B1

B3

B2

Master GI2007

23

Production lines without buffers

24

Assumptions

M1

B1

M2

B2

M3

B3

M4

If a machine breaks down or it takes longer time for an

operation,

then all other machines must wait.

(immedicate propagration of disruptions)

Impact : the productivity of the line is usually smaller than that

of the bottleneck machine.

25

Case of reliable machines with different cycle times

t1 1

t2 2

M1

M2

The progress of products in the line is synchronized to allow

the completion of all on-going operations .

The cycle time of the line is that of the slowest machine, i.e.

TH MIN U i MIN

i

2

i

2

1

ti

M1 wait

2

26

Failure-prone lines with identical cycle times

M1

B1

M2

B2

M3

B3

M4

Assumptions:

When a machine breaks down, all other machines must wait.

The probability of two machines failed at the same time is small

enough and can be neglected. (true in practice)

27

Failure-prone lines with identical cycle times

M1

B1

M2

B2

M3

B3

M4

Productivity:

TH

U

li

1

i mi

1

li

t 1

i mi

28

Proof

1) Each time interval can be decomposed as follows:

UP

M4

All UP

UP

M2

UP

M1

some machine DOWN

2) tn : instant when the line produces n parts. The time interval

[0, tn) includes :

3)

•

a total duration of nt of all UP periods,

•

for each machine Mi, nt/MTBFi failures requiring with total repair

time of (nt/MTBFi) MTTRi.

tn nt

i

nt

MTTRi

MTBFi

l

nt 1 i

i mi

n

1

x tn

l

t 1 i

i mi

TH lim

29

Impact of the length of the line

The longer the line is, the higher the capacity loss is.

Unlimited buffer U/(1l/m)

0,6

0,5

Throughput

0,4

lost capacity

0,3

Zero-buffers

U/(1nl/m)

0,2

0,1

0

0

5

10

15

20

Nb machines

30

Aggregation of parallel machines and

consecutive dependent machines

31

Aggregation

M5

M1

B1

M2

M3

M4

B6

B4

M7

M6

consecutive

dependent machines

M1

B1

M234

parallel

machines

B4

M56

B6

M7

32

Aggregation of parallel machines

M1

M2

Meq

MS

Identical parallel machines : ti = t = 1/U, li = l, mi = m

Ueq = S×U

leq = l

meq = m

33

Aggregation of parallel machines

M1

M2

Meq

MS

Non Identical parallel machines : ti = 1/Ui, li, mi, ei = 1/(1+ li/mi)

S

U eq U i

leq eeq

i 1

eeq

1

U eq

S

i 1

U i ei

1

1 leq meq

S

i 1

li ei

S

eeq

av failure frequency

availability of Meq

34

Aggregration of consecutive dependent machines

M2

M1

...

Meq

MS

Machines of identical cycle time : ti = t = 1/U, li, mi

leq i 1 li

S

eeq

1

1

E ( L)

leq

meq

1

S li 1

i 1

meq

leq mi

Failure rate equivalence

1

S li

1 i 1

mi

Flow rate equivalence

Average stoppage time equivalence

35

Aggregration of consecutive dependent machines

Machines of nonidentical cycle time : ti = 1/Ui, li, mi

• All machines slowed down to slowest one :

U = min{Ui, i= 1, ..., S}

• Reduced failure rate : li = Uli /Ui

• Equivalent machine cycle time : Ueq = U

• Failure rate equivalence : leq = Si li

• Flow rate equivalence : THeq = TH(L)

1

S li 1

i 1

• Average stoppage time equivalence

meq

leq mi

36

Two-machine production lines with

intermediate buffer

37

Motivation & cost of intermediate buffers

M1

B1

M2

B2

M3

B3

M4

Motivation:

• Avoid loss of production capacity

Costs:

• Increasing WIP and production delay

• Larger factory space

• More complicated material handling

Effect of failures:

• Unlimited buffer : no upward propagation of disruptions

• No buffer: Instantaneous propagation

• Finite buffers : delayed and partial propagations

38

Motivation & cost of intermediate buffers

New phenomena:

•Blocking

Failure of M3

•Starvation

M1

M2

M3

M4

M3

M4

3t time units after the failure

where t is the cycle time

M1

M2

39

CTMC model of

reliable line with exponential processing times

M1

B

M2

Assumptions:

• The two machines are reliable and never fail

• The processing times are exponentially distributed random

variables with mean 1/p1 on M1 and 1/p2 on M2

• The buffer capacity is K

• Each machine can hold a part on it for processing.

• M1 is never starved and M2 is never blocked

40

CTMC model of

reliable line with exponential processing times

B

M1

M2

The following state variable

X(t) = number of parts in B

+ the part on M2 if any

+ the finished part blocked on M1 if any

is a continuous time Markov chain

p1

0

p1

…

1

p2

p1

p2

p1

K+1

p2

K+2

p2

41

CTMC model of

reliable line with exponential processing times

M1

B

M2

CTMC model equivalent to M/M/1/(K+2).

0

1 r

n

,

r

0 , if r 1

n

K 3

1 r

1

n

, if r 1

K 3

with r = p1/p2, corresponding to the traffic intensity.

p1

0

p1

…

1

p2

p1

p2

p1

K

p2

K+2

p2

42

CTMC model of

reliable line with exponential processing times

Performance measures (case r ≠ 1)

Starving probability of M2 : 0 = (1-r)/(1-rK+3)

Blocking probability of M1: K+2 = rK+2(1-r)/(1-rK+3)

Throughput rate :

TH = p2(1-0) = p1(1-K+2) = p1(1- rK+2)/(1-rK+3)

Mean WIP

K 2

r

E X n n

K 3

1

r

n 0

1 r K 2

K 2

( K 2) r

1 r

43

CTMC model of

reliable line with exponential processing times

Example : p1 = 10, p2 = 9, r = 10/9

0,4

0,35

0,3

0,25

Blocking prob.

0,2

9,5

Unlimited buffer

9

0,15

0,1

starving prob

8,5

0,05

0

0

7,5

5

10

15

20

25

30

35

Buffer capacity

7

30

Zero-buffer

6,5

25

6

20

5,5

5

0

5

10

15

20

Buffer capacity

25

30

35

Encours

Throughput

8

15

10

5

0

0

5

10

15

20

Buffer capacity

25

30

35

44

Exponential model of Failure-prone lines

M1

B

M2

Assumptions:

• Machines can break down.

• Exponentially distributed times to failures and time to repair

with TBFi = EXP(li) and TTRi = EXP (mi)

• Exponential processing times with T1 = EXP(p1) and T2 =

EXP(p2)

• Buffer of capacity K

• Each machines holds the part in process.

• M1 never starved and M2 never blocked

45

Exponential model of Failure-prone lines

M1

B

M2

The system can be described by the following state variables:

x = number of parts in B + part on M2 if any + finished part

blocked on M1 if any

ai = 1 if Mi is UP and 0 if Mi is DOWN

The state vector (a1, a2, x) is a continuous time Markov chain

46

Exponential model of Failure-prone lines

0, 0, 0

0, 0, 1

0, 0, 2

1, 0, 0

1, 0, 1

1, 0, 2

m2

0, 1, 0

m1

0, 1, 1

l1

1, 1, 0

0, 1, 2

l2

p2

1, 1, 1

1, 1, 2

p1

Exponential model of the case K = 0

• Analytical expressions of steady-state probabilities

available in the book of SB Gershwin

• Can be used to evaluate the performance measures

47

Slotted time model of a failure-prone line

Assumptions

M1

B

M2

• Synchronized line, i.e. ti = t, with a buffer of capacity N.

• All parts remain in buffers and machines do not hold parts.

• Slotted time indexed t = 1, 2, 3, …

• Machine state change at the begining of a period: machine working (W),

under repair (R), blocked (B), starved (I).

• Buffer state change at the end of a period.

• Blocking Before Service: M1 blocked if B is full, M2 starved if B is empty

• A machine Mi in state W in t breaks down in period t+1 with proba pi and, with

proba 1 - pi, moves to state W or B or I.

• A machine Mi in state R in t moves to state W in t+1 with proba ri and, with

proba 1 - ri, remains in R.

• A machine in B or I in t moves to W in t+1 if the other machine is repaired.

48

Slotted time model of a failure-prone line

Discrete Time Markov chain

M1

B

M2

The state vector (a1, a2, x) with

• ai(t) = 1/0 depending on whether Mi is UP or DOWN at the

begining of t

• x(t) = number of parts in B at the end of t

is a discrete time Markov chain.

Buffer state change :

• x(t) = x(t-1) + a1(t)×1{x(t-1)<N} - a2(t)×1{x(t-1)>0}

• 0≤x(t) ≤ N

49

Slotted time model of a failure-prone line

Discrete Time Markov chain

M1

B

M2

Transient states :

• (1, 0, 0), (1, 1, 0), (0, 0, 0), (1, 0, 1)

• (0,0,N), (0,1,N), (1,1,N), (0,1,N-1)

Flow balance equations for states (a1, a2, x) with 2 ≤ x ≤ N-2

(1,1,x) = (1-p1)(1-p2)(1,1,x) + r1(1-p2)(0,1,x) + (1-p1)r2(1,0,x) + r1r2(0,0,x)

(0,0,x) = (1-r1)(1-r2)(0,0,x) + p1(1-r2)(1,0,x) + (1-r1)p2(0,1,x) + p1p2(0,0,x)

(1,0,x) = (1-p1)p2(1,1,x-1) + (1- p1)(1-r2)(1,0,x-1) + r1p2(0,1,x-1) + r1(1-r2)(0,0,x-1)

(0,1,x) = p1(1-p2)(1,1,x+1) + (1-r1)(1-p2)(0,1,x+1) + p1r2(1,0,x+1) + (1-r1)r2(0,0,x+1)

Other boundary equations can be derived similarly.

50

Slotted time model of a failure-prone line

Discrete Time Markov chain

M1

B

M2

Performance measures :

• Efficiency of M1 : E1 = Sa1 = 1, x < N (a1, a2, x)

• Efficiency of M2 : E2 = Sa2 = 1, x > 0 ( a1, a2, x)

• Throughput rate : TH = E1×U = E2×U

• WIP : S x( a1, a2, x)

• Probability of starvation : (0, 1, 0)

• Probability of blocking : (1, 0, N)

51

Slotted time model of a failure-prone line

Analytical results

Efficiency of the line E(N) = probability a machine is producing

1 r * N

,

if I1 I 2

* N

1 I1 (1 I 2 ) r

E(N)

r1 r2 r1r2 r1r2 (1 I ) N

,if I1 I 2 I

( r r )(1 2 I ) r r (1 I )2 ( N 1)

1 2

1 2

a1 p1 p2 p1 p2 r1 p2

a 2 p1 p2 p1 p2 r2 p1

1 r1 r2 r1r2 p1r2

2 r1 r2 r1r2 p2 r1

p

a

rp

1 2 , r* 1 2 1 , Ii i

2a1

r2 p1 2

ri

WIP to be determined with expressions of steady-state

probabilities available in the book of S.B. Gerswhin

52

Continuous flow models of failure-prone lines

Assumptions

M1

B

M2

Only synchronuous lines are considered, i.e. Ui = U.

Each machine produces continuously.

When a machine Mi produces,

• a flow moves out of its upstream buffer at rate U

• a flow is injected in its downstream buffer at rate U

53

Continuous flow models of failure-prone lines

How good is continuous flow approximation

M1

B

M2

The continuous flow model is a good approximation for a high

volume production line with large enough buffer capacity.

Theorem (David, Xie, Dallery):

THContinuous(h) < THDiscret(h) < THContinuous(h+2)

where THDiscret (h) is a discrete flow line similar to the

Exponential model but with constant processing times and

buffer capacity h.

Result holds for longer lines.

54

Continuous flow models of failure-prone lines

Dynamic behavior

M1

B

M2

Model parameters:

li: failure rate of Mi

mi: repair rate of Mi

• U: maximum production rate of Mi

• h : buffer capacity

State variables

ai(t) =1/0 : state of machine Mi at time t

• x(t): buffer level at t (a real variable)

Auxillary variable:

•ui(t) : production rate of Mi at t

55

Continuous flow models of failure-prone lines

Dynamic behavior

u1(t)

h

u2(t)

M1

B

M2

a1(t)

x(t)

a2(t)

u1 = U

u1 = U

u1 = 0

u1 = U

u1 = 0

u1 = 0

a1 = 1

a1 = 1

a1 = 1

a1 = 1

a1 = 0

a1 = 0

u2 = U

u2 = 0

u2 = 0

u2 = U

u2 = U

u2 = 0

a2 = 1

a2 = 0

a2 = 0

a2 = 1

a2 = 1

a2 = 1

x(t)

F2

blocking

R2

F1

Starving

R1

F2

56

Continuous flow models of failure-prone lines

Dynamic behavior

u1(t)

M1

a1(t)

u2(t)

B

x(t), h

M2

a2(t)

Blockage of M1 : a1(t) = 1, x(t) = h, a2(t) = 0

Starvation of M2 : a1(t) = 0, x(t) = 0, a2(t) = 1

In all other case : u1(t) = a1(t) U, u2(t) = a2(t) U

57

Continuous flow models of failure-prone lines

Performance measures

online proof

Efficiency of the line, E(h) that is the probability a machine

is producing

Throughput rate :

TH(h) = E(h)U

Probability of starving of M2:

ps(h) = 1 – E(h)/e2

Probability of blocking of M1:

pb(h) = 1 – E(h)/e1

Isolated efficiency of Mi :

ei = 1/(1+Ii) = mi/(li+mi)

Mean buffer level:

Q(h)

58

Continuous flow models of failure-prone lines

Analytical solution

Case I1 = l1/m1 I2 = l2/m2

E (h)

Q (h)

a

I 2 eah I1

I 2 (1 I 2 ) e ah I1 (1 I1 )

I1 I 2 m1 m2

U

1 e ah I 2 (1 I 2 ) he ah

I 2 I1 m1m2

(

)

I 2 (1 I 2 ) eah I1 (1 I1 )

l2 m1 l1m2 l1 l2 m1 m2

U

( l1 l2 )( m1 m2 )

59

Continuous flow models of failure-prone lines

Analytical solution

Case I1 = l1/m1 I2 = l2/m2 = I

E (h)

l l

1 I

h 1 2 U

I

l1l2

(1 I )2 h

I

(1 2 I )

l1 l2

U

l1l2

h I l1 l2

(1 I ) 1

U

2 l1

m2

Q (h)

h

l1 l2

2

1

I

h

I

1

2

I

U

( )

(

)

2

l1l2

60

Continuous flow models of failure-prone lines

Analytical solution

Case U=1, l1 m1 l2 m2 = 0,1

0,55

infinite buffer

0,5

Throughput

0,45

In this case,

0,4

Q(h) = 0,5h

zero-buffer

0,35

0,3

0,25

0,2

0

50

100

150

200

250

300

350

Buffer capacity h

61

Numerical results

U = 1, l1 = 0.1, m2 = 0.1, l2 = 0.1

Throughput

m1 = 0,14

m1 = 0,12

m1 = 0,10

m1 = 0,08

m1 = 0,06

Buffer capacity

Discussions:

Why are the curves increasing?

Why do there reach an asymptote?

What is TH when N= 0?

What is the limit of TH as N tends to infinity?

Why are the curves with smaller m1 lower?

62

Numerical results

U = 1, l1 = 0.1, m2 = 0.1, l2 = 0.1

WIP

m1 = 0,14

m1 = 0,12

m1 = 0,10

m1 = 0,08

m1 = 0,06

Buffer capacity

Discussions:

• Why are the curves increasing?

• Why different asymptotes?

• What is the limit of WIP as N→?

• Why are the curves with smaller m1 lower?

63

Numerical results

U = 1, l1 = 0.1, m2 = 0.1, l2 = 0.1

Questions :

• If we want to increas production rate, which machine should

we improve?

• What would happen to production rate if we improved any

other machine?

64

Numerical results

U = 1, l1 = 0.1, m1 = 0.1, m2 = 0.1, l2 = 0.1

Throughput

Improvement to nonbottleneck machine.

Same graph for

improvement of

machine 2

Buffer capacity

65

Numerical results

U = 1, l1 = 0.1 , m1 = 0.1, m2 = 0.1, l2 = 0.1

Average inventory

Inventory increases as

the (non-bottleneck

upstream machine is

improved and as the

buffer space is

increased.

Buffer capacity

66

Numerical results

U = 1, l1 = 0.1 , m1 = 0.1, m2 = 0.1, l2 = 0.1

Average inventory

• Inventory decreases

as the (non-bottleneck)

downstream machine

is improved

•Inventory increases as

the buffer space

isincreased.

Buffer capacity

67

Numerical results

U = 1, m2 = 0.8, l2 = 0.09, h = 10

Should we prefer short and frequent disruptions or long

and infrequent disruptions?

Throughput

•

l1 and m1 vary together and

m1/(l1 + m1) = 0.9

• Answer: short and frequent

failures.

• Why?

Repair rate m1

68

Continuous flow models of failure-prone lines

Reversiblity

M1

B

M2

M1

B

M2

L

L'

Reversibility Theorem

(hold for any nb of machine and for all models)

E(L) = E(L')

Q(L) = h - Q(L')

ps(L) = pb(L')

pb(L) = ps(L')

Proof for the continuous L2

line

69

Continuous flow models of failure-prone lines

Dynamic behavior

u1(t)

M1

a1(t)

u2(t)

B

x(t), h

M2

a2(t)

A continuous time Markov process with hybrid state space

characterized by

Internal state distribution (0 < x < h):

Fa1a2(x) = P{a1(t) = a1, a2(t) = a2, 0 < x(t) x}

fa1a2(x) = d Fa1a2(x) /dx

Boundary distribution:

Pa1a2(0), Pa1a2(h)

70

Case I1 = l1/m1 I2 = l2/m2

a

l2 m1 l1m2 l1 l2 m1 m2

U

( l1 l2 )( m1 m2 )

f10 ( x ) f 01 ( x ) Ce ax

f 00 ( x )

l1 l2 ax

m m2 ax

Ce , f11 ( x ) 1

Ce

m1 m2

l1 l2

P11 ( h )

U

l1

Ce ah , P11 ( 0 )

U

l2

C

l1 l2 ah

l1 l2

P10 ( h ) U

Ce , P01 ( 0 ) U

C

l1m2

l2 m1

P01 ( h ) P00 ( h ) P10 ( 0 ) P00 ( 0 ) 0

1 U ( l1 l2 ) 1 I 2 ah 1 I1

e

C l2 m1 l1m2 I1

I2

71

Case I1 = l1/m1 I2 = l2/m2=I

f10 ( x ) f 01 ( x ) C0

C0

I

U

U

P11 ( h ) C0 , P11 ( 0 )

C0

f 00 ( x ) IC0 , f11 ( x )

l1

l2

l1 l2

l1 l2

P10 ( h ) U

C0 , P01 ( 0 ) U

C0

l1m2

l2 m1

P01 ( h ) P00 ( h ) P10 ( 0 ) P00 ( 0 ) 0

l l

1

U 1 2 (1 2 I )

C0

l1l2

(1 I )

I

2

h

72

Long failure-prone production lines

73

Introduction

M1

B1

M2

B2

M3

B3

M4

•

The performance evaluation of a general failure-prone line is difficult

due to the lack of analytical solution and the state space explosion.

•

The number of states for a M machines lines with buffers of capacity N

is about 2M(N+1)M-1. For M = 10 and N = 100, there are over 1021 states.

•

A so-called DDX decomposition method is capable of obtaining an

approximative but precise enough analytical estimation.

•

Other approximation methods exist but the DDX method is considered as

one of the most efficient ones and can be extended to other systems such

as assembly lines.

•

Focus on Continuous flow model but all results can be extended to

discrete flow models

74

Notation

M1

B1

M2

B2

M3

B3

M4

Given isolated machine performances:

Ii = li/mi

ei = 1/(1+Ii) : isolated efficiency of Mi

eiU : isolated productivity of Mi

Unknown system performance measures:

Ei : Probability that Mi is producing

THi = Ei U: throughput rate of Mi

psi : probability of starvation of Mi

pbi : proba of blockage of Mi

75

Aggregation method

Equivalent machine

M1

B1

M2

B2

M1

B1

M2 L12

M3

B3

M4

Replace L12 by a machine M12 of equivalent isolation

throughput rate (flow equivalence), i.e.

1

m12

eM

E ( L12 )

l12

m12

1 l12 / m12

E ( L12 )

12

Repair time of M12 = Average stoppage time of M2 in L12:

P(a 2 0)m2

ps( L12 )m1

1

1

1

m12 P(a 2 0)m2 ps( L12 )m1 m2 P(a 2 0)m2 ps( L12 )m1 m1

P(a 2 0) 1 E ( L12 ) ps( L12 )

76

Aggregation method

Equivalent machine

M1

B1

M2

M12

B2

B2

M3

B3

M4

M3

B3

M4

M123

B3

M4

M1234

Repeating the aggregation process leads to an approximated

estimation of the throughput of the line.

77

Decomposition method

Properties of a continuous line

M1

B1

M2

B2

M3

B3

M4

Flow conservation:

THi = TH1, i = 2, …, K

(1)

Ei = E1, i = 2, …, K

(2)

Flow-idle time relation:

Ei = ei (1- psi –pbi) , i = 2, …, K (3)

Proof:

Ei = P{ai(t) = 1 & Mi not blocked & Mi not starved}

= P{ai(t) = 1 | Mi not blocked & Mi not starved}. P{Mi not blocked & Mi not starved}

= ei (1- psi –pbi)

since the proba that Mi is blocked and starved simultaneously is null in continuous flow

model.

78

Decomposition method

Decomposition

Decompose a K-machine line into K-1 lines of two-machines

L:

L(1)

M1

B1

M2

l1

m1

h1

l2

m2

Mu(1)

B(1)

Md(1)

lu(1)

mu(1)

h1

ld(1)

md(1)

B2

h2

B3

M4

l3

m3

h3

l4

m4

Mu(i) = upstream subline of Bi

Md(i) = downstream subline of Bi

Mu(2)

B(2)

lu(2)

mu(2)

h2

Objective: the input/output flow of

B(i) is similar to that of Bi in L

M3

Md(2)

L(2)

ld(2)

md(2)

Mu(3)

B(3)

Md(3)

lu(3)

mu(3)

h3

ld(3)

md(3)

L(3)

79

Decomposition method

Decomposition

Notation :

Iu(i), eu(i), Id(i), ed(i)

E(i) : proba that Md(i) is producing

ps(i) : proba of starvation of Md(i)

pb(i) : proba. of blockage of Mu(i)

From the objective of decomposition:

E(i) = Ei+1, i = 1, …, K-1

(4)

ps(i) = psi+1 , i = 1, …, K-1

(5)

pb(i) = pbi , i = 1, …, K-1

(6)

80

Decomposition method

Decomposition

Apply(3) to L(i):

E(i) = eu(i)(1- pb(i)) , i = 1, …, K-1

(7)

E(i) = ed(i)(1- ps(i)) , i = 1, …, K-1 (

8)

Combine (2) & (4)

E(i) = E(1) , i = 1, …, K-1

(I)

Combine (3), (4), (5), (6),

E(i-1) = ei (1 - ps(i-1) - pb(i))

Combining with (7) & (8)

Id(i-1) + Iu(i) = 1/E(i-1) + Ii –1

(II)

81

Decomposition method

Decomposition

Repair time of Mu(i) :

A) Failure of Mu(i)

= failure of Mi, with prob. 1- a

= failure of Mu(i-1), with prob. a

B) Repair time of Mu(i)

MTTRu(i) = aMTTRu(i-1) + (1-a) MTTRi

1/mu(i) = a/mu(i-1) + (1-a) /mi

(9)

where a = percentage of stoppages of Mu(i) caused by a failure of Mu(i-1)

82

Decomposition method

Decomposition

C)

nb of flows interruptions of B(i-1)

=

a

ps ( i 1) mu ( i 1)

E ( i ) lu ( i )

nb of flow resumptions of B(i-1)

(10)

Nb of failures of Mu(i)

State-transition of Mu(i)

lu(i)

E(i) working

DOWN

mu(i)

idle

83

Decomposition method

Decomposition

Combine (9)-(10),

ps ( i 1) mu ( i 1) 1

1

mu ( i ) E ( i ) I u ( i ) mu ( i )

E ( i ) I u ( i ) mu ( i ) mi

ps ( i 1)

ps ( i 1) mu ( i 1)

1

mi mu ( i )

E

i

I

i

E ( i ) Iu ( i )

( ) u( )

1

ps ( i 1)

1

mu(i) = X. mu(i-1) + (1-X) mi

(III)

with X = ps(i-1) / (Iu(i).E(i)).

84

Decomposition method

Decomposition

Repair time of Md(i)

md(i) = Y. mu(i+1) + (1-Y) mi+1

(IV)

with Y = pb(i+1) / (Id(i).E(i)).

Boundary equations:

lu(1) = l1, mu(1) = m1, ld(K-1) = lK, mu(K-1) = mK, (V)

85

Decomposition method

Decomposition

Equation system (I) – (V),

(I)

E(i) = E(1) , i = 1, …, K-1

(II)

Id(i-1) + Iu(i) = 1/E(i-1) + Ii –1

(III)

mu(i) = Xmu(i-1) + (1-X) mi with

X

ps ( i 1)

Iu (i ) E (i )

pb ( i 1)

(IV)

md(i) = Ymu(i+1) + (1-Y) mi+1 with Y I ( i ) E ( i )

d

(V)

lu(1) = l1, mu(1) = m1, ld(K-1) = lK, mu(K-1) = mK

• 4(K-1) equation

• 4(K-1) unknowns : lu(i), mu(i), ld(i), md(i)

• E(i), ps(i), pb(i) are functions of lu(i), mu(i), ld(i), md(i)

86

Decomposition method

Decomposition

DDX Algorithm:

Step 1: Initialisation lu(i) = li, mu(i) = mi, ld(i) = li+1, mu(i) = mi+1

Step 2: Forward update lu(i), mu(i) by equation (I)-(II)-(III)

For i = 2 to K-1, do

2.1 Evaluate the line L(i-1) to obtain E(i-1), ps(i-1), pb(i-1)

2.2 From (II), Iu(i) = 1/E(i-1) + Ii –1 - Id(i-1)

2.3 From (III)-(I), mu(i) = Xmu(i-1) + (1-X) mi with X = ps(i-1) / (Iu(i).E(i-1)).

Step 3: Backward update ld(i), md(i) with equations (I)-(II)-(IV)

For i = K-2 to 1, do

3.1 Evaluate the line L(i+1) to obtain E(i+1), ps(i+1), pb(i+1)

3.2 From (II), Id(i) = 1/E(i+1) + Ii+1 –1 - Iu(i+1)

3.3 From (IV)-(I), md(i) = Ymd(i+1) + (1-Y) mi+1 with Y = pb(i+1) / (Id(i).E(i+1))

Step 4: Repeat (2) – (3) till convergence, i.e. E(i) = E(1).

87

Distribution of material in a line with

average buffer

50 identical machines l = 0.01, m = 0.1, U = 1, hi = 20

88

Effect of bottleneck

average buffer

50 identical machines : l = 0.01, m = 0.1, U = 1, hi = 20

except bottleneck at M10 with l10 =0.0375

89

Increase one buffer capacity

8-machines with l = 0.09, m = 0.75, U = 1.2, hi = 30

except h6

Why buffer

increases and

which buffer

decreases?

buffer capacity h6

90

Distribution of buffer capacity

Which has a higher throughput rate?

9-machine line with two buffering options:

• 8 buffers equally sized

M1

B1

M2

B2

M3

B3

M4

B4

M5

B5

M6

B6

M7

B7

M8

B8

M9

• 2 buffers equally sized

M1

M2 M3

B3

M4

M5 M6

B6

M7

M8 M9

91

Distribution of buffer capacity

Throughput

All machines have

l = 0.001, m =

0.019, U = 1

What are the

asymptotes

Is 8 buffers always

faster?

Total buffer space

92

Distribution of buffer capacity

Throughput

Is 8 buffers always

faster?

Perhaps not, but the

difference is not

significant in

systems with very

small buffers.

Total buffer space

93

Design buffer space distribution

Design the buffers for a 20-machine production line

The machines have been selected, and the only decision

remaining is the amount of space to allocate for in-process

inventory.

The goal is to determine the smallest amount of inprocess inventory space so that the line meets a

production rate target.

94

Design buffer space distribution

The common operation time is one operation per minute.

The target production rate is 0.88 parts per minute.

95

Design buffer space distribution

Case 1 : MTBF = 200 minutes and MTTR = 10.5 minutes

for all machines (ei = 0.95 parts per minute)

Case 2 : Like Case 1 except Machine 5. For Machine 5,

MTBF = 100 and MTTR = 10.5 minutes (ei = 0.905 parts

per minute)

Case 3 : Like Case 1 except Machine 5. For Machine 5,

MTBF = 200 and MTTR = 21 minutes (ei = 0.905 parts per

minute)

96

Design buffer space distribution

Are buffers really needed?

Line

Production rate with no buffer

Case 1 0.487

Case 2 0.475

Case 3 0.475

Yes. How to compute these numbers? (homework)

97

Design buffer space distribution

Optimal buffer space distribution

Observation:

Buffer space is needed most where buffer level variability is

greatest!

98