vent sizing - UCSB College of Engineering

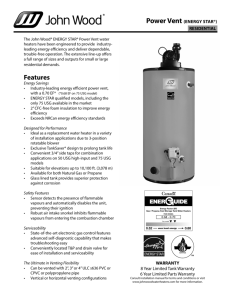

advertisement

Aniket Shende 61 Rahul Sheth 62 Kunal Shinde 63 Advait Soni 64 Chaitanya Sudrik 65 Venting systems include Venting devices, piping or vent header systems, disposal systems Vent systems required for Purging, Cleaning Safety Considerations Venting devices Valves-PRVs, PSVs -conventional , balanced Rupture disks, Breaking Pins Pressure Vacuum Vents Sizing of Relief Valves k 1 2 k k k 1 r F2 r 1 r k 1 3 Critical flow Pcf 2 P1 k 1 A W 520 K d P1K b A W 735K d F2 k k 1 T Z(k -1) 2Mk TZ MP1 (P1 P2 ) 4 Relief headers Worst case scenarios Standard pressure drop calculations Disposal Systems Quenching, Chilling Separation of vapors and liquids Flares- ground, elevated 5 No universal method of vent sizing for all situations If vent size is too large then the venting system becomes uneconomical If it is inadequate then it can cause accidents Codes: API 2000 standards NFPA 30 OSHA 6 Complex fluid dynamic process Discharge flow, pressure decay depend on gas properties, vent line configuration, gas flow Cf V0 Mu Pice (Pf-ce Pi-ce ) t A r Ac M c Pf Pi Vo 1 P ZRT i M c Pf 1 Mi Pi 1 7 Process considerations 1)Valve malfunction, equipment failure 2) Sudden rise in feed inlet pressure 3) Runaway exothermic reactions 4) Process gas exceeding explosion limits 5) Dust explosion Fire considerations 1) External fire adjacent to pressurized vessels 2) External Ignition • K- factor Method RUST Method Vent Ratio Method Nomograph or Cubic law Method 9 Factor K Method by Simmonds and Cubbage For compact rectangular vessels Max. explosion pressure in vented vessel related to vent area Av Pmax F Av K F Av is area of smallest side For St 2 gas mixtures Pred 0.25K - 0.2 barg K 0.8 40Pred Vessel volume between 1 to 1000 m3 L/D ratio less than 5:1 Does not account for vent ducts 12 Spherical flame front propogation Used for equipments in soap and detergent industries Rust equation 2 3 2.72 x 10-4 C(Pmax V) dP F 0.5 Pred dt max The shape factor C is defined as bc C 0.65 2 a 1 3 D C 0.76 L 2 3 13 Limited to maximum rate of pressure rise of 345 bar /s L/D ratio should be less than 2.5:1 Does not account for vent ducts 14 Put forth by Palmer (1973) Vent Ratio = Area of Vent Volume of vessel Simplest method for sizing of vents 15 Vent ratios for various size ranges provided Vent ratios on the basis of experiments in Hartmann apparatus The Hartmann apparatus measures the maximum rate of pressure rise in the vessel for a given size range 16 Maximum Rate of Pressure Rise (bar/s) Vent Ratio (1/m) <345 1/6.1 <690 1/4.6 >690 1/3.1 17 • Can be used for vessels of up to 30 cu.m only • For larger vessels, predicted vent size much greater than actually required and hence uneconomical • Assumes homogenous conditions and rapid propagation of flame throughout the reactor – conditions true in case of smaller vessels 18 Volume Range (cubic m) Modification 30-300 Vent ratio reduced linearly from 1/6 to 1/25 300-600 1/9.2 >700 1/3.1 19 Method developed by Heinrich and Bartknetcht Based on a cubic relation between maximum rate of pressure rise and inverse of the volume (dP/dt)max α V ^ (-1/3) 20 Nomographs are used to determine vent size 21 P stat - the vent opening pressure P red – reduced pressure from P max First determine the P red From the volume of the reactor and P red draw a horizontal line onto the second graph and intersect it with the appropriate K st value The horizontal axis gives the vent area 22 Lowest pressure is 0.2 barg Vessel volume must be between 1 and 1000 cubic m The vessel Length: Diameter ratio should be lesser than 5:1 23 Weak vessels- Vent ratio method Low maximum rate of pressure size-RUST method Turbulent dust clouds- Vent ratio method 24 Vessel Shape- for conical vessels Nomograph method more suitable For cylindrical vessels K- factor method more useful 25 Thank You 26