BE105_7_viscoelasticity

advertisement

Lecture # 7 Viscoelastic Materials

spring

Young’s modulus

(stiffness)

reminder:

solids resist strain:

fluids resist rate of change of length:

F = k1 x

F = k2 d(x)/dt

dashpot

viscosity

most biomaterials (including bone) are viscoelastic

step

responses

fluid

solid

s

e

time

s

viscoelastic

s

e

e

viscoelastic materials may be modeled with springs and dashpots.

e.g.

in series

in parallel

= Maxwell Model

= Voigt Model

Maxwell Model

spring

expands

‘isotonic’

response

(constant

stress)

Voigt Model

dashpot

relaxes

spring

contracts

dashpot acts

as strut

dashpot

expands

e

e

s

s

dashpot

acts as strut

dashpot

acts as strut

dashpot

relaxes

dashpot

relaxes

zero

stress

‘isometric’

response

s

(constant

strain)

s

e

e

= stress

relaxation

curve

acts as

spring

acts as

spring

= damper

or low pass filter

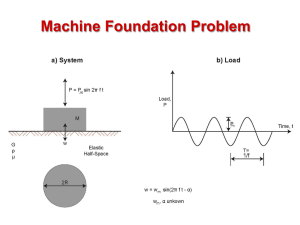

I) Harmonic Analysis of Materials

force

input:

e(t) = e0sin wt

stuff

length

output:

s(t) = s0sin wt + d

Case 1: input in phase with output:

stress and strain maximum

(and minimum) at same time.

input:

e(t) = e0sin wt

s

output:

s(t) = s0sin wt

e

material is acting as an elastic solid, described by single term:

E = s0/e0

E = Young’s modulus

Case 2: output phase advanced by 90o

input:

e(t) = e0sin wt

stress is maximum

when de/dt is maximum

s

e

output:

s(t) = s0sin wt – 90o

material is acting like Newtonian fluid, described by single term:

m = s0/(we0)

using…

e(t) = e0sin wt

de(t)/dt = we0cos wt

m = dynamic viscosity

Case 3: -90o < output phase < 0o :

stress is maximum

at intermediate point

input:

e(t) = e0sin (wt)

s

e

output:

s(t) = s0sin (wt – d)

{0o < d < 90o }

Material is acting as a viscoelastic substance.

output waveform s(t), can be described as the sum of two different waveforms:

in phase component = s’0 sin (wt)

out-of-phase component = s”0 sin (wt – 90o)

= s”0 cos (wt)

out-of-phase

component:

s’

s’’

in phase

component:

Input strain: e(t) = e0sin wt

Output stress: s(t) = s’0sin (wt) + s’’0cos(wt)

= e0 (E’ sin wt + E’’ cos wt)

Let s’=e0E’ and s’’=e0E’’

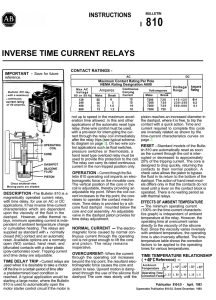

Case 3, continued

E* = complex modulus = s0/e0

E’ = E* cos d

E’’ = E* sin d

viscous,loss

out-of-phase axis

elastic

component

E’

E*

E’’

viscous

component

d

elastic,storage

in-phase axis

E’ = E* cos d = elastic, storage, in-phase, or real modulus

E’’ = E* sin d = viscous, loss, out-of-phase, or imaginary modulus

tan d = E’’/E’

Questions for reflection:

1) What similarities do springs and dashpots have with resistors and capacitors?

2) What would it mean to have a negative viscous modulus?

3) Could you repeat this analysis at different frequencies?

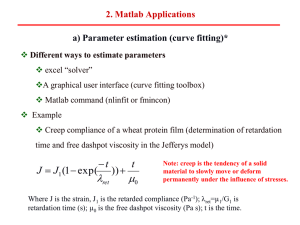

Creep

Harmonic Analysis is valid only for small stresses and strains.

What about large deformations and long time periods?

creep

yield

E

creep = slow decrease

in stiffness,

material starts to flow.

e

s

time

log time

‘necking’

creep

creep

continuous

stress

material makes slow ‘solid to fluid transition’

Phylum Cnidaria

nematocyst

Metridium

Prey (Stomphia)

Predator (Dermasterias)

Collagen

Part III: Collagen

Most common protein in vertebrate body BY FAR!

20% of a mouse by weight.

33% glycine, 20% hydroxyproline

Each tropo-collagen fiber held together by hydrogen bonds

involving central glycines:

glycine

1

2

3

1

fiber

within fiber

construction:

Julian Voss-Andreae's sculpture Unraveling Collagen (2005)