Slides Session 5, Kratena

advertisement

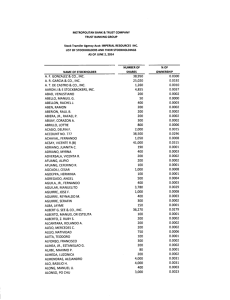

WIOD Consortium Meeting Sevilla, 25 – 26, May, 2011 Embodied and induced technical change and the price of carbon Kurt Kratena Michael Wueger Technical change in E3 modelling Literature: embodied and induced technical change • Models increasingly integrate features of endogenous technical change: WITCH (Bosetti et al., 2006), CGE (Otto, Loeschel and Reilly, 2008) • Endogenous innovation: (i) energy saving R&D, (ii) learning by doing for carbon-free technologies • Popp (2002): energy saving innovation, Sue Wing (2006): technical change induced by climate policy climate policy creates the cost savings of it’s own measures Critical issues and questions • Induced innovation or diffusion of (existing) technologies? • Difference between substitution of factors (for example K and E) and technical change (Binswanger and Ruttan, 1978 and Sue Wing, 2006) • Are K and E substitutes or complements ? Does embodied and induced technical change only work with K and E substitutability ? Technical change in E3 modelling K,L,E,M (Translog) model of production with embodied and induced technical change • Factor bias & TFP (Binswanger and Ruttan, 1978; Jorgenson and Fraumeni, 1981, Jorgenson, 1984) • Embodied technical change (Berndt, Kolstad and Lee,1993; Sue Wing and Eckaus, 2007) • From embodied to induced technical change: K as short-run fixed factor plus investment function (first results with EUKLEMS data in Kratena, 2007) • Model of dynamic factor demand (Pindyck and Rotemberg, 1983): forward looking, but no explicit adjustment costs • Application to WIOD data (YL files, environmental satellites accounts) combining with EUKLEMS (release March 2008, including energy inputs) and IEA Energy Prices and Taxes Technical change in production Dynamic factor demand model: general • Dynamic cost functions with short-run variable costs VC (prices pv of variable factors L, E, M), investment costs (K = capital stock, pI = investment price), gross output Q, labour L (second nest: different skills) , energy E, TFP, returns to scale and technical change bias min e r (t ) VC t ( pv , K , Q, t ) p I ( K K ) dt • Shephard’s Lemma and Euler condition: VC v p v p I (r ) VC 0 K • Euler condition without explicit adjustment costs just states that the shadow price of K equals the user costs of K. Dynamic factor demand model Translog model with non-constant returns to scale logVC 0 Q log Q E log( p E / p M ) log p M L log( p L / p M ) 1 1 1 K log K t t tt t 2 QQ (logQ) 2 LL (log( p L / p M )) 2 2 2 2 1 1 LE log( p L / p M ) log( p E / p M ) EE (log( p E / p M )) 2 KK (log K ) 2 2 2 QL log Q log( p L / p M ) QE log Q log( p E / p M ) QK log Q log K KL log K log( p L / p M ) KE log K log( p E / p M ) tQ t log Q tK t log K tL t log( p L / p M ) tE t log( p E / p M ) pL L s L L LL log( p L / p M ) LE log( p E / p M ) KL log K QL log Q tL t VC pE E s E LE log( p L / p M ) EE log( p E / p M ) KE log K QE log Q tE t VC Dynamic factor demand model Translog model with constant returns to scale logVC 0 Q log Q E log( p E / p M ) log p M L log( p L / p M ) 1 Q log K 1 1 t t tt t 2 LL (log( p L / p M ))2 LE log( p L / p M ) log( p E / p M ) 2 2 K K 1 EE (log( p E / p M ))2 KL log log( p L / p M ) KE log log( p E / p M ) 2 Q Q 1 1 2 2 QK log Q log K log Q log K 2 2 K tL t log( p L / p M ) tE t log( p E / p M ) tK t log Q K pL L s L L LL log( p L / p M ) LE log( p E / p M ) KL log tLt VC Q K pE E s E E LE log( p L / p M ) EE log( p E / p M ) KE log tE t VC Q Dynamic factor demand model Embodied and induced technical change • Derivation of the shadow price of capital derivation of the optimal stock K*: log K * log K * 1 KK 1 QK K (1 QK log Q KL log( p L / p M ) KE log( p E / p M ) tK t s K ) QK log Q KL log( p L / p M ) KE log( p E / p M ) tK t s K Q • Impact of energy price on K* (long-run) log K * KE log p E KK log K * KE log p E QK • Returns to scale ( measures the cost effect of Q): logVC Q QQ logQ QL log( p L / p M ) QE log( p E / p M ) QK log K tQt logQ • Increasing returns to scale: < 1. Dynamic factor demand model Capital stock adjustment and energy • Forward looking adjustment of K to K*: log Kt 1 log Kt 1 t (logKt*1 ) log Kt 2 log Kt log Kt 1 • Investment function (non-constant returns to scale) s K ,t 1 K 1 log(K t 1 ) 1 log K t t KL log( p L,t 1 / p M ,t 1 ) KE log( p E ,t 1 / p M ,t 1 ) QK log Qt 1 tK t 1 KK 2 log K t log K t 1 • Input-output spill-overs of technical change through production of capital goods: p = VC/Q + pKK/Q p I p I Mˆ B Bij pim Mˆ B Bij • With Bij as the investment matrix (industries * commodities) for imports (MB) and domestic deliveries Dynamic factor demand model Embodied and induced technical change:energy • Elasticity of E to K: KE log E KE z K K log K sE VC • Long-run elasticity of E: EE s E2 s E EE d log E log E log K * d log p E sE log K * log p E EE s E2 s E EE KE z k K KE sE s VC E KK EE s E2 s E EE KE z k K KE sE s VC E QK Dynamic factor demand model Estimation methodology • Balanced panel for: AUT, DNK, FIN, NLD, GB, from 1980-2006 • GMM estimation with lagged exogenous (factor prices, output, capital stock, depreciation rate, rate of return) as instruments the expectation of K*t+1 is determined by all information in t capital stock adjustment can be due to expectation errors or shocks • Estimating the full system with VC-function, factor demand for L and E and investment function ( log Kt+1) for non-constant and constant returns to scale • Deriving returns to scale, own price elasticities, capital/energy and capital/labour elasticities (calculating shadow price of K), as well as long-run elasticities of E • Restrictions: homogeneity, symmetry and concavity of the cost function (individual, for ‘problem cases’) Dynamic factor demand model Data from WIOD, EUKLEMS and IEA (energy prices) • Energy inputs in physical units (TJ) by about 20 energy carriers from WIOD environmental accounts • IEA Energy Prices and Taxes for most of the energy carriers/countries (estimating missing data to fill gaps) • Constructing an aggregate energy input in current prices (pE *E), volumes (E), and price of energy pE. The volume measure is based on aggregation of energy contents effective input (‘energy services’ like ‘labour servives’ and ‘capital srvices’ in EUKLEMS) • Capital stock, GFCF deflators, depreciation rate (capital input files from EUKLEMS), benchmark interest rate (EUROSTAT), deflated with VA deflator (YL files, WIOD) user costs pI(r + ) • ‘Labour services’ (L) , compensation of employees from (pL*L) price of labour (pL) , data from YL files, WIOD Dynamic factor demand model Estimation results: non-constant returns to scale Food, beverages and tobacco Textiles, leather and footwear Wood and cork Pulp and paper, printing Coke, refined petroleum and nuclear fuel Chemicals and chemical products Rubber and plastics Other non-metallic minerals Basic metals and fabricated metal Machinery Electrical and optical equipment Transport equipment Other manufacturing K LL LE EE KK KL KE -0.3064 (0.1235) -0.7704 (0.1366) -1.8256 (0.3106) -1.1688 (0.6125) -0.1471 (1.0648) 1.5429 (0.2262) -0.8230 (0.6449) -1.5436 (0.2738) -0.3972 0.0577 (0.0245) 0.0168 (0.0329) 0.1528 (0.0262) 0.0109 (0.0285) -0.0091 (0.0195) 0.1510 (0.0207) 0.0839 (0.0195) -0.0326 (0.0219) 0.1629 -0.0144 (0.0022) -0.0051 (0.0035) -0.0156 (0.0061) 0.0085 (0.0094) -0.0526 (0.0062) -0.0008 (0.0092) 0.0027 (0.0099) -0.0249 (0.0074) -0.0188 0.0121 (0.0009) 0.0131 (0.0018) 0.0110 (0.0000) 0.0250 (0.0001) 0.0658 (0.0146) 0.0229 (0.0078) 0.0011 (0.0122) 0.0550 (0.0001) 0.0417 -0.0337 (0.0811) 0.3874 (0.1214) -1.1409 (0.1446) 0.6118 (0.3202) -0.8335 (0.2745) 1.2024 (0.2953) -1.1749 (0.4804) 0.4000 (0.1644) -0.1735 0.0619 (0.0156) 0.0041 (0.0160) 0.0340 (0.0173) 0.0421 (0.0165) -0.0240 (0.0085) 0.1722 (0.0178) 0.1260 (0.0259) 0.0138 (0.0109) 0.1723 0.0148 (0.0015) 0.0025 (0.0017) -0.0003 (0.0045) -0.0045 (0.0097) 0.0050 (0.0181) -0.1248 (0.0136) -0.0149 (0.0275) 0.0441 (0.0105) -0.0581 *** *** *** ** *** *** (0.1947) ** -0.2171 (0.2187) -0.0358 (0.1468) -0.2724 (0.3201) -1.2236 (0.1927) *** ** *** *** *** (0.0211) *** 0.1076 (0.0132) *** 0.0690 (0.0316) 0.1700 (0.0000) *** 0.0358 (0.0328) *** * *** *** *** *** (0.0074) *** -0.0012 (0.0025) -0.0005 (0.0045) 0.0134 (0.0065) ** -0.0082 (0.0076) (0.0052) 0.0054 (0.0011) 0.0070 (0.0000) 0.0072 (0.0031) 0.0136 (0.0006) *** *** *** *** *** *** ** *** *** *** *** ** *** (0.1242) 0.4780 (0.1223) -0.1320 (0.0443) -0.5835 (0.1525) -0.1043 (0.0295) *** *** ** *** *** * ** *** *** *** *** (0.0104) 0.1012 (0.0066) 0.0639 (0.0130) 0.0574 (0.0187) 0.1448 (0.0144) *** ** ** *** *** *** *** *** *** *** *** *** * *** * *** (0.0063) *** 0.0000 (0.0014) -0.0019 (0.0017) 0.0009 (0.0032) 0.0016 (0.0057) 25 parameters out of 91 are insignificant Embodied energy saving technical change: wood and cork, pulp and paper/printing, chemicals, rubber and plastics, basic metals and fabricated metal, electrical and optical equipment Dynamic factor demand model Estimation results: constant returns to scale Food, beverages and tobacco Textiles, leather and footwear Wood and cork Pulp and paper, printing Coke, refined petroleum and nuclear fuel Chemicals and chemical products Rubber and plastics Other non-metallic minerals Basic metals and fabricated metal Machinery Electrical and optical equipment Transport equipment Other manufacturing Q LL LE EE KL KE QK 1.7855 (0.1243) 1.5012 (0.0785) 1.1515 (0.2228) 0.0481 (0.2789) 3.3571 (0.5714) 0.9078 (0.0889) 0.9011 (0.1146) 0.6591 (0.2074) 1.1697 0.0859 (0.0100) -0.0390 (0.0213) 0.1358 (0.0185) -0.1672 (0.0392) -0.0430 (0.0177) 0.1553 (0.0000) 0.0542 (0.0174) 0.1429 (0.0156) 0.1699 -0.0036 (0.0017) -0.0060 (0.0037) 0.0060 (0.0057) 0.0464 (0.0181) -0.0463 (0.0066) 0.0367 (0.0072) 0.0297 (0.0102) 0.0101 (0.0059) -0.0115 0.0151 (0.0000) 0.0123 (0.0013) 0.0163 (0.0025) 0.0212 (0.0107) 0.0393 (0.0095) -0.0117 (0.0063) 0.0266 (0.0082) 0.0513 (0.0001) 0.0372 0.0658 (0.0058) -0.0561 (0.0118) 0.0125 (0.0123) -0.0966 (0.0124) -0.0272 (0.0075) 0.1763 (0.0146) 0.0974 (0.0154) -0.0381 (0.0077) 0.0914 0.0090 (0.0006) 0.0030 (0.0011) 0.0084 (0.0025) 0.0423 (0.0038) -0.0080 (0.0124) -0.1656 (0.0130) -0.0479 (0.0169) 0.0160 (0.0041) -0.0325 0.8386 (0.1582) 0.2458 (0.1347) 0.5162 (0.4424) -1.2639 (0.4518) 3.7159 (0.7940) -4.2503 (0.7219) -0.1035 (0.0553) -1.2287 (0.3890) 0.3441 (0.0752) -0.0441 (0.0976) 1.1576 (0.0234) 2.0841 (0.1248) 1.0372 (0.0730) *** *** *** *** *** *** *** *** *** *** *** (0.0000) 0.1694 (0.0141) 0.0766 (0.0218) 0.1703 (0.0000) -0.0429 (0.0224) *** * *** *** ** *** *** *** *** *** *** *** * (0.0112) 0.0205 (0.0018) 0.0062 (0.0035) 0.1035 (0.0097) -0.0301 (0.0036) ** * ** *** *** *** * *** * *** *** (0.0040) 0.0047 (0.0013) 0.0061 (0.0013) 0.0141 (0.0030) 0.0132 (0.0004) *** *** *** ** *** * *** *** *** *** *** *** *** (0.0071) 0.1205 (0.0057) 0.0719 (0.0106) 0.0339 (0.0101) 0.1364 (0.0072) *** *** *** *** *** *** *** *** *** *** *** *** (0.0034) 0.0064 (0.0008) 0.0008 (0.0010) 0.0179 (0.0031) 0.0188 (0.0030) *** *** *** *** *** *** *** *** *** *** *** (0.1777) -1.7631 (0.2056) -0.0281 (0.0127) 1.0262 (0.1425) 0.4420 (0.0990) *** * *** *** *** * *** * *** ** *** *** 8 parameters out of 91 are insignificant Embodied energy saving technical change: Coke, refined petroleum and nuclear fuel, chemicals, basic metals and fabricated metal Dynamic factor demand model Estimation results: non-constant returns to scale t Food, beverages and tobacco Textiles, leather and footwear Wood and cork Pulp and paper, printing Coke, refined petroleum and nuclear fuel Chemicals and chemical products Rubber and plastics Other non-metallic minerals Basic metals and fabricated metal Machinery Electrical and optical equipment Transport equipment Other manufacturing tt tK tL tE -0.0380 (-0.0025) *** -0.0236 (-0.0053) *** -0.0287 0.0000 (0.0001) -0.0002 (-0.0001) * 0.0002 -0.0037 (-0.0010) *** 0.0048 (-0.0016) *** 0.0022 -0.0005 (0.0009) -0.0028 (-0.0011) *** -0.0038 0.0006 (-0.0001) *** 0.0005 (-0.0001) *** 0.0003 (-0.0070) -0.0408 (-0.0144) 0.1636 (-0.0434) 0.0146 (0.0076) -0.0591 (0.0102) -0.0179 (0.0045) 0.0104 (0.0066) -0.0305 (0.0070) 0.0159 (0.0127) 0.0019 (0.0056) -0.0539 (0.0053) (-0.0001) -0.0001 (0.0001) -0.0020 (0.0007) 0.0006 (0.0002) 0.0001 (0.0002) -0.0001 (0.0001) 0.0004 (0.0001) 0.0002 (0.0001) 0.0013 (0.0001) 0.0003 (0.0002) 0.0001 (0.0002) (0.0028) -0.0062 (0.0058) -0.0067 (0.0073) 0.0161 (0.0053) -0.0237 (0.0063) 0.0157 (0.0019) -0.0088 (0.0027) -0.0012 (0.0025) 0.0027 (0.0026) 0.0002 (0.0022) -0.0103 (0.0021) (-0.0007) -0.0028 (-0.0009) -0.0009 (0.0007) -0.0037 (0.0009) -0.0023 (0.0006) -0.0007 (0.0006) -0.0046 (0.0007) -0.0059 (0.0003) -0.0083 (0.0012) -0.0073 (0.0006) -0.0033 (0.0011) (-0.0001) 0.0003 (0.0004) 0.0036 (0.0011) -0.0030 (0.0005) 0.0006 (0.0005) -0.0009 (0.0003) -0.0003 (0.0003) -0.0002 (0.0001) -0.0004 (0.0002) -0.0004 (0.0002) 0.0011 (0.0003) *** *** *** ** *** * *** *** * *** *** ** *** * *** ** *** *** *** *** *** *** *** *** *** *** *** *** *** * *** *** *** *** *** ** *** Factor bias: (i) labour saving in all industries, (ii) energy saving in: chemicals, other non-metallic minerals, basic metals and fabricated metal, machinery, electrical and optical equipment, and transport equipment Dynamic factor demand model Estimation results: constant returns to scale t Food, beverages and tobacco Textiles, leather and footwear Wood and cork Pulp and paper, printing Coke, refined petroleum and nuclear fuel Chemicals and chemical products Rubber and plastics Other non-metallic minerals Basic metals and fabricated metal Machinery Electrical and optical equipment Transport equipment Other manufacturing tt tK tL tE 0.0014 (0.0047) 0.0159 (0.0046) *** -0.0315 0.0001 (0.0002) -0.0008 (0.0002) *** 0.0011 0.0143 (0.0039) *** 0.0247 (0.0029) *** -0.0176 -0.0017 (0.0005) *** -0.0016 (0.0009) * -0.0037 0.0003 (0.0001) *** 0.0004 (0.0001) *** -0.0002 (0.0063) -0.0178 (0.0071) 0.0737 (0.0222) -0.0122 (0.0031) -0.0490 (0.0066) -0.0298 (0.0063) -0.0331 (0.0036) 0.0120 (0.0069) -0.0231 (0.0019) -0.0040 (0.0044) -0.0371 (0.0043) (0.0003) 0.0002 (0.0003) -0.0043 (0.0013) 0.0011 (0.0002) 0.0026 (0.0004) 0.0019 (0.0004) 0.0017 (0.0002) -0.0002 (0.0002) 0.0014 (0.0001) 0.0007 (0.0002) 0.0014 (0.0002) (0.0085) -0.0122 (0.0061) 0.0465 (0.0186) 0.0643 (0.0113) -0.0062 (0.0061) 0.0109 (0.0041) -0.0003 (0.0030) 0.0217 (0.0057) 0.0178 (0.0012) 0.0224 (0.0036) -0.0141 (0.0028) (0.0007) 0.0041 (0.0012) -0.0004 (0.0006) -0.0026 (0.0004) -0.0013 (0.0006) -0.0044 (0.0004) -0.0037 (0.0003) -0.0061 (0.0004) -0.0084 (0.0008) -0.0053 (0.0004) -0.0008 (0.0009) (0.0002) -0.0013 (0.0006) 0.0044 (0.0007) -0.0060 (0.0004) -0.0017 (0.0004) -0.0014 (0.0002) -0.0009 (0.0003) -0.0004 (0.0001) -0.0004 (0.0001) -0.0020 (0.0002) 0.0020 (0.0002) *** ** *** *** *** *** *** * *** *** *** *** *** *** *** *** *** *** *** ** ** ** *** *** *** *** *** *** *** *** *** ** *** *** *** *** *** ** *** *** *** *** *** *** *** *** *** Factor bias: (i) labour saving in all industries except pulp and paper, (ii) energy saving in a majority of industries Dynamic factor demand model Estimation results: elasticities, non-constant returns to scale Food, beverages and tobacco Textiles, leather and footwear Wood and cork Pulp and paper, printing Coke, refined petroleum and nuclear fuel Chemicals and chemical products Rubber and plastics Other non-metallic minerals Basic metals and fabricated metal Machinery Electrical and optical equipment Transport equipment Other manufacturing EE LL EK LK -0.2595 -0.0791 -0.1494 -0.1339 -0.1092 -0.5682 -0.4759 -0.0160 -0.0742 -0.4165 -0.0810 -0.2061 -0.0397 -0.4773 -0.6458 -0.1316 -0.6706 -1.1677 -0.0404 -0.4773 -0.7898 -0.1115 -0.3362 -0.4551 -0.0220 -0.6047 0.8845 0.1587 0.0489 -0.1159 0.2276 -1.9717 -0.2467 0.5935 -1.1123 -0.0240 -0.1248 0.1149 0.0783 0.3742 -0.0010 0.2075 0.1824 -0.3925 0.7897 0.6514 -0.0936 0.7391 0.3023 0.3502 0.2678 0.3875 1.0165 1.0126 0.8908 0.9614 0.8844 1.0518 0.7445 1.1096 0.9279 1.0028 0.8846 1.0052 1.0005 price elasticity of E : - 0.2, of L : - 0.5 . Negative energy/capital elasticities (K and E are substitutes): pulp and paper/printing, chemicals, rubber and plastics, basic metals and fabricated metal, machinery, electrical and optical equipment Energy saving embodied technical change Dynamic factor demand model Estimation results: elasticities, constant returns to scale Food, beverages and tobacco Textiles, leather and footwear Wood and cork Pulp and paper, printing Coke, refined petroleum and nuclear fuel Chemicals and chemical products Rubber and plastics Other non-metallic minerals Basic metals and fabricated metal Machinery Electrical and optical equipment Transport equipment Other manufacturing EE LL EK LK -0.0766 -0.1292 -0.1035 -0.2587 -0.1422 -1.0836 -0.1107 -0.0772 -0.1676 -0.4928 -0.2030 -0.0906 -0.0702 -0.3066 -0.8412 -0.1998 -1.3081 -2.0352 -0.0191 -0.5175 -0.2258 -0.0853 -0.1390 -0.4283 -0.0208 -0.7703 0.5721 0.1972 0.5357 1.5026 -0.0056 -2.7513 -1.5797 0.3545 -0.6477 0.5788 0.1732 1.9192 1.3564 0.4304 -0.2049 -0.0466 -0.2380 -0.6921 0.6553 0.2704 -0.0330 0.3698 0.2823 0.3288 0.1459 0.4615 Negative energy/capital elasticities (K and E are substitutes): coke, refined petroleum and nuclear fuel, chemicals, rubber and plastics, basic metals and fabricated metal Three industries show energy saving embodied technical change in both specifications: chemicals, rubber and plastics, basic metal/fabricated metal Dynamic factor demand model Estimation results: embodied and induced technical change • Two industries with embodied energy saving technical change in the case of non-constant returns to scale, but not with constant returns: pulp and paper/printing, electrical and optical equipment • Are non-constant returns to scale an additional source of technical change? (some industres with decreasing returns !) • Main disadvantage of this approach: • (Price) induced technical change is only possible, when K and E are substitutes and investment reacts positive to energy price shocks further reduction of number of industries with embodied plus induced energy saving technical change Dynamic factor demand model Estimation results: long-run price elasticities of E non-constant rs non-constant rs Food, beverages and tobacco Textiles, leather and footwear Wood and cork Pulp and paper, printing Coke, refined petroleum and nuclear fuel Chemicals and chemical products Rubber and plastics Other non-metallic minerals Basic metals and fabricated metal Machinery Electrical and optical equipment Transport equipment Other manufacturing constant rs constant rs EE EE EE EE -0.2595 -0.0791 -0.1494 -0.1339 -0.1092 -0.5682 -0.4759 -0.0160 -0.0742 -0.4165 -0.0810 -0.2061 -0.0397 0.1276 -0.0801 -0.1494 -0.1347 -0.1078 -0.7728 -0.9150 -0.0815 0.2981 -0.4165 -0.0792 -0.2059 -0.0364 -0.0766 -0.1292 -0.1035 -0.2587 -0.1422 -1.0836 -0.1107 -0.0772 -0.1676 -0.4928 -0.2030 -0.0906 -0.0702 0.0503 -0.1309 -0.1036 -0.2437 -0.1422 -1.3512 -0.0920 -0.1400 -0.0022 -0.4928 -0.2055 0.5446 -0.0613 Starting point: industries with embodied energy saving technical change Is there also induced energy saving technical change ? = Is the long-run price elasticity of E higher than the short-run ? Dynamic factor demand model Embodied & induced technical change Non-constant returns to scale Starting point: industries with embodied energy saving technical change: pulp and paper/printing, chemicals, rubber and plastics, basic metals and fabricated metal, machinery, electrical and optical equipment Long-run elasticity of E (EE) > short-run elasticity (EE) = induced technical change: pulp and paper/printing, chemicals, rubber and plastics, machinery Dynamic factor demand model Embodied & induced technical change Constant returns to scale Starting point: industries with embodied energy saving technical change: coke, refined petroleum and nuclear fuel, chemicals, rubber and plastics, basic metals and fabricated metal Long-run elasticity of E (EE) > short-run elasticity (EE) = induced technical change: chemicals Conclusions and Future Research Conclusions • Dynamic Translog factor demand model allows for diverse sources/types of technical change: returns to scale, TFP, factor bias, embodied and induced technical change. • Technical change/progress is only partly energy saving, also for embodied technical change • Disadvantage: embodied technical change is only energy saving, if E and K are substitutes induced technical change is only energy saving, if E and K are substitutes plus if investment reacts positively to energy prices. Future research • Allowing for embodied technical change in the case that E and K are complements vintage model for aggregate K.