Simple Is Beautiful - Penn State University

advertisement

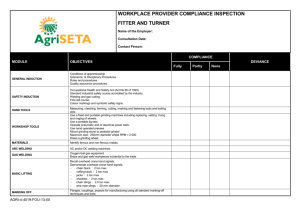

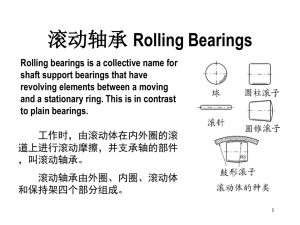

Simple Is Beautiful – Refreshing thinking in engineering modeling and beyond Liming Chang Professor Penn State University Guest Professor National Chung Cheng University Implications of Simplicity • Deep understanding leads to simple approaches to problem solving • Simple solutions often generate time-lasting significance • Ability to solve a complex problem simply is the highest level of competency Three examples……. I. An Analytical Model for the Basic Design Calculations of Journal Bearings R. K. Naffin and L. Chang http://www.mne.psu.edu/chang/me462/finite-journal.pdf A basic journal bearing 3 p 3 p dh h h 6U x x z z dx Long-bearing model (L/D > 3) 3 p 3 p dh h h 6U x x z z dx 3D 3 L (4 2 2 2 2 )1 / 2 W 4c 2 (2 2 )(1 2 ) Short-bearing model (L/D < 1/4) 3 p 3 p dh h h 6U x x z z dx DL (0.62 1) W 8c 2 (1 2 ) 2 3 2 1/ 2 A finite-bearing model Define a dimensionless load: c2 W W 4 D Then (0.62 2 1)1 / 2 W 8(1 2 ) 2 L D 3 3 (4 2 2 2 2 )1 / 2 L W 2 2 4(2 )(1 ) D for short bearings for long bearings Take log: (0.62 2 1)1 / 2 L log W log 3 log 2 2 8(1 ) D 3 (4 2 2 2 2 )1 / 2 L log W log log 2 2 4(2 )(1 ) D Or, Y f S ( ) 3 X short bearings Y f L ( ) X long bearings Approximate finite bearings by: Y f ( , X ) c3 X 3 c2 X 2 c1 X co Y f L ( ) X Y f S ( ) 3 X II. A Theory for the Design of Centrally-Pivoted Thrust Bearings L. Chang http://www.mne.psu.edu/chang/me462/JOT_slider.pdf Centrally-pivoted plane-pad thrust bearing Classical lubrication theory fails to predict 3 p 3 p dh h h 6 U x x y y dx B 0 B pxdx xc pdx 0 Potential mechanisms of lubrication • Viscosity-temperature thermal effect Load capacity by thermal effect A simple thermal-lubrication model: assumptions • • • • Infinitely wide pad Conduction heat transfer negligible Convection heat transfer at cross-film average velocity Uniform shear-strain rate A simple thermal-lubrication model: equations Reynolds equation: d h 3 dp dh 6U dx dx dx B B Pad equilibrium: Temperature equation: U dT U 0 c 2 dx (hi ho ) / 2 Oil ~ T relation: oe (T T ) 0 pxdx 0.5 pdx 0 2 o Temperature distribution Temperature rise 8Cth T ln1 X 2 (1 H ) Dimensionless variables: T T X x/B H hi / ho UBo Cth 2 ho c 0 X 1.0 Pressure distribution Pressure p( X ) A( X ) c1 B( X ) c2 p ho2 Uo B A( X ) 6 p B( X ) 0 X 1.0 dX 8Cth 2 1 X (1 H ) 2 H ( H 1) X dX 8Cth 3 1 X (1 H ) 2 H ( H 1) X 1.0 Pad equilibrium UBo Given Cth 2 ho c 0 1.0 pXdX 0.5 pdX 0 solve for p(X ) and H hi / ho Bearing dimensionless load parameter, Wth Load and dimensionless load 1.0 B 0 0 w pdX ho2 U o B ho2 p d ( x / B) w 2 U o B Bearing load parameter UBo ho2 w Cth w 2 w Wth 2 ho c Uo B c B = viscosity-temperature coefficient ~ 0.04 oC-1 = lubricant density ~ 900 kg/m3 c = lubricant specific heat ~ 2000 J/kg-oC w/B = bearing working pressure ~ 5.0 MPa Wth ~ 0.1 One-to-one relation between Cth and Wth Bearing film thickness, ho ho 0.65hmax hmax = outlet film thickness under isothermal maximum-load-capacity condition (X = .58 ) Verification with numerical results for square pad Wth 0.05 0.65hmax 0.6hmax Wth 0.17 Further development of the theory for finite pads Y. Yan and L. Chang – Tribology Transactions, in press Infinitely-wide pad d h 3 dp dh 6U dx dx dx Finite-width pad 3 p 3 p dh h h 6U x x z z dx ho/hmax results 0.7 N=0 o Relative film thickness, h /h iso 0.6 N=0.5 N=1.0 0.5 0.4 0.3 N=2.0 0.2 0.1 0 0 0.02 0.04 0.06 0.08 0.1 0.12 Bearing load parameter, W th 0.14 0.16 III. Research on gear meshing efficiency L. Chang and Y. R. Jeng Manuscript in review Meshing of a spur gear pair Meshing loss can be less than 0.5% of input power Meshing of a spur gear pair Governing equations Reynolds equation h3 p u1 u2 h h x 12 x 2 x t Load equation xo w(t ) p(s, t )ds xi Film-thickness equation 2 xo sx h( x, t ) ho (t ) g ( x, t ) r ( x, t ) p ( s , t ) ln ds x E ' i s 2 Temperature equation 2T T kf c u 0 f f f 2 z x xo Friction calculated by f (t ) x ( x, z, t ) |z 0dx i Experimental repeatability scatter Test number Pinion speed (rpm) Pinion toque (Nm) 1 6000 413 2 6000 546 3 6000 684 4 8000 413 5 8000 546 6 8000 684 7 10000 413 8 10000 546 9 10000 684 Repeatability amounts to 0.04% of input power Well, simple is beautiful! • Hertz pressure distribution • Parallel film gap • Numerical solution of temperature equation Thermal shear localization Upper surface w 1.0 0.8 No localization Z 0.6 0.4 0.2 With localization 0.0 1.90 1.95 2.00 2.05 2.10 Velocity, m/s Lower surface Cross-film velocity Effects of shear localization on oil shear stress Effect of load on gear meshing loss Effect of speed on gear meshing loss Effect of gear geometry – module Theory vs. experiment Experiment Test number 1 2 3 4 5 6 7 8 9 Pinion speed (rpm) 6000 Pinion toque (N-m) 413 6000 6000 8000 8000 546 684 413 546 8000 10000 684 413 10000 10000 546 684 Theory Effect of gear geometry – pressure angle Effect of gear geometry – addendum length Oil property – viscosity-pressure sensitivity Oil property – viscosity-temperature sensitivity Effect of gear thermal conductivity Shear stress reduction with one surface insulated w Summary • Clever simple approaches to problem solving can help reveal fundamental insights and/or produce key order-of-magnitude results/trends. • It is no small feat to develop a mathematic model that is simple and generally applicable. • The significance of a simple model of general validity can be tremendous and long lasting.