IntroCompFracMech

J.Cugnoni, LMAF-EPFL, 2014

Stress based criteria

(like Von Mises) usually define the onset of

“damage” initiation in the material

Once critical stress is reached, what happens?

In this case, a defect is now present (ie crack)

The key question is now: will it propagate?

If yes, will it stop by itself or grow in an unstable manner.

Stress concentrator:

Critical stress is reached…

A crack is formed…

Will it extend further?

If yes, will it propagate abruptly until catastrophic failure?

Stress singularity

Assumed

Crack extension dA

Fracture test: measure force at failure and calculate K

Ic

From analytical solutions or FE

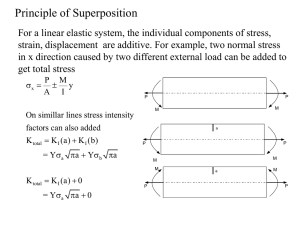

Crack propagation : stress intensity factor

◦ Stress intensity factors K tip.

I

, K

II

, K

III measure the intensity of stress singularity at crack

“Stress intensity factor”:

◦ Constants of the 1/sqrt(r) term in stress field at crack tip:

“Critical Stress intensity factor”:

◦ Maximum K that a material can sustain, considered as a material property and indentified in standard fracture tests.

Units: Pa/sqrt(m), symbol: K

Ic

K

IIc

K

IIIc

Crack propagation occurs if

K > Kc with K=K ic

+K

IIc

+K

IIIc

In many materialy, propagation is mode I dominated:

K

I

>K

Ic

Potential energy: P 0=U0-V0

Assumed

Crack extension dA

Crack propagation : an “energetic” process

◦ Extend crack length: energy is used to create a new surface (break chemical bonds).

◦ Driving “force”: internal strain energy stored in the system

“Energy release rate”:

◦ Change in potential energy P (strain energy and work of forces) for an infinitesimal crack extension dA. Units: J/m2, Symbol: G

◦ measure the crack “driving force”

Potential energy: P 1= P 0 –E r

And E r

= G*dA

New crack surface dA:

Dissipates E d

=Gc*dA

“Critical Energy release rate”:

◦ Energy required to create an additionnal crack surface. Is a material characteristic (but depends on the type of loading). Units: J/m2, symbol: G c

Crack propagation occurs if G > Gc

Using numerical simulation method we can:

◦ Apply Finite Element, Finite Volume/Difference,

Boundary Element or Meshfree methods

◦ To obtain approximations of displacement, force, stress and strain fields in arbitrary configuration.

And then? To apply fracture mechanics, we need:

◦ to compute fracture mechanics parameters (SIF

K, G) in 2D and 3D configurations;

◦ to compute J integral in elastic-plastic analyses ;

◦ to simulate crack growth (under general mixedmode conditions);

FE simulation of a compact tension fracture test

Calculation of K (linear elasticity):

◦ Stress or displacement field matching (single / mixed mode)

◦ Indirectly from G (Interaction integrals in mixed mode)

Calculation of G:

◦ Finite difference of potential energy (linear, evtl. non linear)

◦ Compliance method (linear)

◦ Virtual Crack Closure Technique VCCT (linear, mixed mode)

◦ J-integral (non-linear)

Simulate crack growth

◦ to VCCT criterion, node release, remeshing or XFEM

◦ Cohesive elements / interfaces (Damage mechanics)

Idea:

◦ compare FE stress field at crack tip with theory,

◦ fit K

I from the numerical stress value

◦ In LEFM (for r 0):

0)

yy

K

I

/ 2

r

( ) (eq 4.36a)

Step 1: From FE: Extract stress field Syy at =0 (along crack direction)

Fitting method 1: Plot (as a function of r, for r 0)

K

I

r lim

0

2

yy r

Fit region

Fit a line over the quasi constant region of the plot, identify K

I either as average value or as the intercept at r=0

x

In theory the plot should be linear as:

yy

K

I

(1/ 2

r )

( )

K x

I

'

b

r

Fit a line over the quasi linear region of the plot, identify K

I either as the slope of the line

Note : the same method can be applied to get Kii from shear component at theta=0

Idea:

◦ compare FE crack displacement opening field with theory,

◦ fit K

I from the numerical displacement value

◦ In LEFM (for r 0): u

(

)

u y

K

I

4

(

1) r / 2

(eq 4.40b)

Step 1: From FE: Extract stress field Syy at =0 (along crack direction) x

For plane stress:

3

1

For plane strain: = shear modulus=

E 2(1

)

Fitting method 1: Plot (as a function of r=-x, for r 0) u y

r

K

I

4

(

1)

Fit region

Fit a line over the quasi constant region of the plot, identify either as the average value or as the intercept at r=0

K

I

4

(

1)

Fitting method 1: Plot u y as a function x

In theory, the plot should be linear as : u y

K

I

(

1)

4

r

1

r

K

I

(

4

1) x '

Fit a line over the quasi linear region of the plot, the slope is

K

I

(

4

1)

Evaluation of K from stress field requires very fine mesh. To better capture the 1/sqrt(r) stress singularity, one can use singular quadratic elements with shifted mid side nodes at ¼ of edge length

(Barsoum,1976, IJNME, 10, 25; Henshell and Shaw, 1975, IJNME, 9,

495-507)

Using 8 node second order quadrangular elements, if we move the midside nodes at

¼ of edge, we make the Jacobian transformation of the element singular as

1/sqrt(r) along the element edges.

By collapsing all nodes of one edge

(degenerate a quadrangle to a triangle), the 1/sqrt(r) singularity covers then the whole element.

Can be extended into 3D for 20 node hexahedrons

For linear elastic isotropic materials, the following relations link G to K:

G

I

1

8

For plane stress:

I

2

K G

II

3

1

1

8

For plane strain:

II

2

K G

III

1

2

K

II

2

= shear modulus=

E 2(1

)

For Mode I in plane stress and plane strain, this simplifies to:

I

K

I

2

I

2

(1 ) K

I

E E

So knowing either K or G, the other can be determined directly. This can be extended to orthotropic material.

2

◦ compare the strain energy of several FE models with different crack length, calculate the ERR as the derivative of potential energy P = U - F

◦ For a linear elastic material: the potential energy F = P D 2 U thus

P = U – F = - U with the strain energy

U

a

( a

D a

) U a

1

ij ij dV

G

P

2

V

◦ Compute ERR or as the slope of U(a)

Different FE models for a0, a1, a2… a

Equations are for a unit depth, if not the case, compute use U/b instead of U

Idea (similar to experimental test data reduction !)

◦ Calculate the compliance C(a)= D( a ) /P ( a ) for different crack lengths a0, a1 (several FE models required) and fit it with an appropriate function

◦ For a linear elastic material: the ERR can be obtained from the C(a)

◦ G

P

2

2 b

dC da

or G

P

2 b

2

dC da where dC/da is obtained from the fitted curve

D cst

(eq 3.41 & 3.43b)

P, D

Different FE models for a0, a1, a2… a

Using the “J-Integral” approach

(see course), it is possible to calculate the ERR G as linear elasticity.

G = J in

If we know the displacement and stress field around the crack tip, we can compute J as a contour integral: t

σ n

J-integral is path independent for all continuum materials. But G must be perpendicular to the interface if dissimilar materials are used.

W=strain energy density u = displacement field s = stress field

G = contour: ending and starting at crack surface

J-integrals are usually computed from a volume/surface integral in

FE, for example in Abaqus with q = virtual crack extension vector:

With on G and on C. Using divergence and equilibrium equations we can obtain:

J-integral can be extend in 3D by computing J on several “slices” of the model.

However, there are notable 3D effects affecting crack propagation: in 3D, the external surface is free of normal stress, so in plane stress state

For thick specimens, the center of the specimen is closer to plane strain state

S22 on external surface

Plane stress

S22 on symmetry plane

Plane strain => higher stresses

As a consequence, J-integral and G are not constant across the width.

This will lead to a slightly curved crack front during propagation

Need to be careful about specimen size effects when characterizing G or K

In 2D FE simulation: use plane stress for very thin specimens, and plane strain for thick ones.

G is max in the center

=> propagate earlier

G is min on the side

=> propagate last

Results obtained on a relatively coarse 3D mesh to highlight which methods are less mesh sensitive

External surface, plane stress

K1

Stress fit1

3870

(units: Mpa*sqrt(mm))

K1

Stress fit2

4345

Displacement fit1 Displacement fit2

4380 5079

From Jintegral

4337

K from

Abaqus

4540

Inside, plane strain

(* please note that the FE data for u2 and s22 were extracted on free surface, a source of error)

Stress fit1

4345

Stress fit2

3870

Displacement fit1 Displacement fit2

4813 5582

J-integral

5144

K from

Abaqus

5140

Strain energy, forward finite difference

Strain energy, backward finite difference

Strain en. centered finite difference

Strain energy fit

Compliance method

J integ. Avg

G

(units: mJ/mm2)

322 282 302 302.5

301.5

Conclusion:

K determination is more sensitive to mesh !

G calculation using compliance, J-integral or strain energy fit are the most reliable

296

Can be calculated in elasticity

/ plasticity in 2D plane stress, plane strain, shell and

3D continuum elements.

Requires a purely quadrangular mesh in 2D and hexahedral mesh in 3D.

J-integral is evaluated on several “rings” of elements: need to check convergence with the # of ring)

Requires the definition of a

“crack”: location of crack tip and crack extension direction

Quadrangle mesh

Crack plane

Crack tip and extension direction

Rings 1 & 2

Create a linear elastic part, define an “independent” instance in Assembly module

Create a sharp crack: use partition tool to create a single edge cut, then in

“interaction” module, use “Special->Crack->Assign seam” to define the crack plane (crack will be allowed to open)

In “Interaction”, use “Special->Crack->Create” to define crack tip and extension direction (can define singular elements here, see later for more info)

In “Step”: Define a “static” load step and a new history output for J-Integral.

Choose domain = Contour integral, choose number of contours (~5 or more) and type of integral (J-integral).

Define loads and displacements as usual

Mesh the part using Quadrangle or Hexahedral elements, if possible quadratic. If possible use a refined mesh at crack tip (see demo). If singular elements are used, a radial mesh with sweep mesh generation is required.

Extract J-integral for each contour in Visualization, Create XY data -> History output.

!! UNITS: J = G = Energy / area. If using mm, N, MPa units => mJ / mm2 !!!

By default a 2D plane stress / plane strain model as a thickness of 1.

See demo1.cae example file

To create a 1/sqrt(r) singular mesh:

◦ In Interaction, edit crack definition and set “midside node” position to

(=1/4 of edge) & “ side, single node ”

0.25

collapsed element

◦ In Mesh: partition the domain to create a radial mesh pattern as show beside.

Use any kind of mesh for the outer regions but use the “ quad dominated, sweep ” method for the inner most circle. Use quadratic elements to benefit from the singularity.

◦ Refine the mesh around crack tip significantly.

39

38,8

38,6

38,4

38,2

38

37,8

37,6

Contour 1 Contour 2 Contour 3

Regular mesh

Singular Mesh

Contour 4 Contour 5

Stress analysis

•Perform a stress analysis

•Locate stress critical regions

Crack analysis

•Assume the presence of a defect in those regions (one at a time)

•Consider different crack lengths and orientation

•For each condition, check if the crack would propagate and if yes if it is stable or not

Design evaluation

•Define operation safety conditions: maximum stress / crack length,… before failure occurs

•Define damage inspection intervals / maintainance plan

Abaqus tutorials:

◦ http://lmafsrv1.epfl.ch/CoursEF2012

Abaqus Help:

◦ http://lmafsrv1.epfl.ch:2080/v6.8

◦ See Analysis users manual, section 11.4 for fracture mechanics

Presentation and demo files:

◦ http://lmafsrv1.epfl.ch/jcugnoni/Fracture

Computers with Abaqus 6.8:

◦ 40 PC in CM1.103 and ~15 in CM1.110