Printing speed - Matan Digital Printers

advertisement

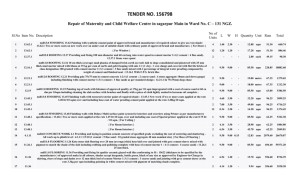

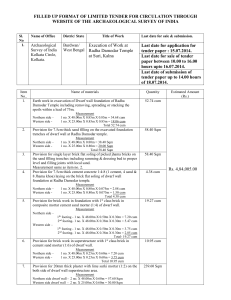

UViStar - Best Alternative vs. HP Scitex TJ8600 The UViStar Printers Line The UViStar printer is a wide format printer available at 3 or 5 meter widths, capable of printing multi rolls & different files per roll It includes a selection of print modes and print qualities, from POP with PDS technology (20&40 pL droplets) to BB Selection of options that enable printing ANY type of application and deliver finished images directly from the UViStar Click on the bellow links (internet connection required) https://dl.dropbox.com/u/32825694/In-line%20Finishing.wmv https://dl.dropbox.com/u/32825694/FB_UViStar%20Pro8.wmv With an unmatched Performance of 353 sqm/h and Quality/Value ratio, the UViStar is the first choice for all highquality and high performance applications The UViStar winning configuration vs. TurboJet UViStar2 • • • • UViStar wit slitters & X cutter X Cutter 6 Slitters Wrinkle analyzer Anti Static bar This is the recommended configuration to win against TJ All options remains available including: • Backlit • Flatbed • 8 colors PDS with Pro8 UViStar with its new capabilities is a better choice for traditional TJ applications TurboJet Overview HP Scitex TJ8600 is based on Scitex solvent Turbojet platform First introduced in 2006 as TJ8500 with maximum print speed of up to 400 sqm / hr Since then, roll to roll printers speed has improved with clear advantage of versatility of applications The information in this presentation is based also on customers that replaced TJ8600 with UViStar printer UViStar Versatility Printing speed Many applications and media SAV&Paper - BB only Up to 25mm on many types at any length 20&40 pl drop size Optional rigid, backlit, 8 colors Freefall R2R, Roll2Sheet Cut both X&Y 0.5mm, size limited by Drum 55pL drop size Roll2Sheet only Fotoba external cutter Max 353 sqm\hr Effective 288 sqm/hr MultiRoll of different files Cost of ownership Low 2-4 PH, 12-18KW, 175mm lamps Running cost HP Scitex TJ8600 Ink consumption 50% better 145-180 sqm/liter Due to Drum limitations High $65K more annually 15-30PH, 88KW, 1.6m UV Lamp $100K more annually 100 sqm/liter Additional Comparison Information Print speed and printer utilization Print modes and actual speeds Spectrum of applications TJ8600 Vs. Pro8 In-line Finishing Cost of Ownership - TJ8600 Maintenance TJ8600 - Print Speed and Printer utilization Spec Maximum print speed is 480 sqm / hr This speed is calculated on full drum diameter of 3.7m and width 1.6m Practically – the drum is not utilized for it full diameter, only 60-70% Meaning maximum print speed is 288 – 336 sqm / hr • UViStar Pro 8 maximum speed is 353 sqm The illustration bellow demonstrates file size of 1.6m x 2.4 printed on the drum (64% utilization) 3.7m drum length, BUT only 2.4m is the actual size 1.6 m width 3.7m diameter 1.6 m width TJ8600 - Print Modes and Actual Speeds The TJ8600 has 3 main print modes Print mode Spec speed Resolution Actual speed (65%, due to drum) High quality 120 600 dpi 78 sqm Quality 240 448 dpi 156 sqm Production 480 336 dpi 312 sqm In production mode the printed image is in very low density Due to low ink density the production mode is not sellable quality (Specially in black in blue) Spectrum of applications TJ Vs. UViStar The TJ8600 main application is paper billboards Few other applications can be printed but with printing limitation; sizes and media types Very limited in applications Product Paper & SAV BB PVC Banner PE Bus shelters Rigid Building Backlit materials wraps & D/S Flag & Textile s TJ8600 Yes *Partial No Yes No No No No UViStar Yes Yes Yes Yes Yes Yes Yes Yes *Limited in printed size and in media thickness Special media that needs to be pre cut (more expensive) In - line Finishing TJ8600 with Fotoba cutter TJ8600 • In length axis - cuts the media accurately • In width axis - Fotoba or other process –~$80,000 UViStar • In length axis – Built-in cutter • In width axis – Slitters available for multi roll mode or several slitters on wide media (3.2 or 5 m banner) Slitters Final job after cutting Cost of Ownership TJ8600 Maintenance The TJ8600 is very expensive for maintenance Service contract fee is $4,000 per month x 12 = $48,000 per year (excluding print heads) UV Lamp size is 1.6m and is very expensive to replace The TJ8600 has 150 print heads • Missing nozzles effects the print image immediately • Customers replace 15-30 print heads per year TJ8600 Power consumption is 88KW • UViStar Pro8 is 12KW • Electricity bill is 6 times higher The printer includes many sub units such as loading system, PDU, ink system, electronics cabinet – complicated for operation and troubleshooting TJ8600 annual maintenance is ~$60,000-$70,000 In Summary HP Scitex TJ8600 is mainly paper BB printer Real speed is lower than spec - 288 sqm/hr Limited applications vs. UViStar Maintenance cost is very high: $60,000-$70,000 per year UViStar Best/lowest ink consumption– up to 180 sqm/liter, annual savings can reach $100,000 TJ have cannot print Backlit and Rigid media UViStar delivers a better solution for TJ application and is all-in-one solution for indoor & outdoor with low cost of ownership Automatic Double-sided Printing Automatically prints double-sided jobs with perfect alignment between both sides Camera-guided software algorithm detecting any misalignment between the two sides and automatically corrects registration for perfectly aligned double sided prints Simple and easy fully automatic system Eliminates the need for guesswork and manual manipulation Reduces required operator skill level Automatic Loader & Unloader Feeding automatically multiple units of rigid media Controlled from touch screen, eliminating the need for manual loading and collecting Minimal manual operator intervention Maximizes utilization of overall machine print time Loading several sheets Load and print automatically Collected automatically Flatbed+ Automatic Loader & Unloader Selection of 4 bed sizes, enables to print up to 3.2 x 2.4 m (126 x 94”) or multiple sheets Option Width Length A 3.3m (10.8ft) 2.5m (8.2ft) B 3.3m (10.8ft) 1.25m (4.1ft) C 1.65m (5.4ft) 2.5m (8.2ft) D 1.65m (5.4ft) 1.25m (4.1ft) Small foot print for easy storage PDS 8 color printing 8-color printing combined with PDS technology Parallel Drop Size Technology enables printing of small ~20pl and ~40pl in the same pass • 20pl drops enhance print quality, fine details and smoother images • 40pl drops achieve coverage High definition POP print quality, while maintaining the same production speed Smooth gradients, skin tones with vivid colors PDS Technology – How it Works 20 PL drops and 40 PL drops at the Some nozzles inject 20 PL drops Some nozzles inject 40PL drops same time Group of Head Carriage PH inject Nozzles inject 20 & 40 20 & 40 PL drops PL drops Result: 40 PL drops for coverage 20 PL drops for fine details Without print speed reduction *PDS is proprietary, patent-pending technology owned by Matan Group of Head Carriage PH inject Nozzles inject 20 & 40 20 & 40 PL PL drops drops