Introduction to Modeling - Rose

advertisement

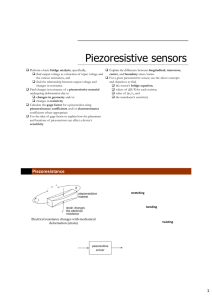

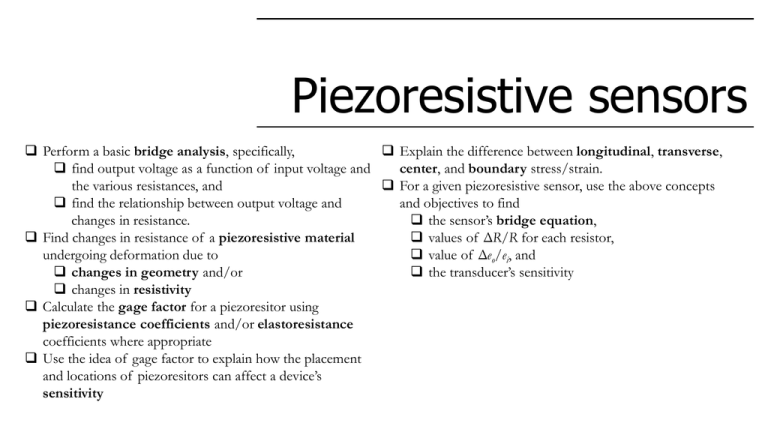

Piezoresistive sensors Perform a basic bridge analysis, specifically, Explain the difference between longitudinal, transverse, find output voltage as a function of input voltage and center, and boundary stress/strain. the various resistances, and For a given piezoresistive sensor, use the above concepts find the relationship between output voltage and and objectives to find changes in resistance. the sensor’s bridge equation, Find changes in resistance of a piezoresistive material values of ΔR/R for each resistor, undergoing deformation due to value of Δeo/ei, and changes in geometry and/or the transducer’s sensitivity changes in resistivity Calculate the gage factor for a piezoresitor using piezoresistance coefficients and/or elastoresistance coefficients where appropriate Use the idea of gage factor to explain how the placement and locations of piezoresitors can affect a device’s sensitivity Piezoresistance Circuit with measurable output voltage proportional to the electrical resistance Electrical resistance changes with mechanical deformation (strain) constant DC voltage input to bridge mechanical input piezoresitive sensor resistance voltage output Wheatstone bridge analysis Te toca a ti Find the relationship between the input and output voltages for the bridge shown. Assume im is zero. R1 R4 e o R3 R4 R1 R 2 ei Find the relationship between R1, R2, R3, and R4 for eo = 0. R1 R 3 R 2 R 4 We would like this output to be zero when there is no mechanical input to the transducer. Bridge balancing Full bridge: All four resistors identical piezoresistors with same value of R, o sea, R1 = R2 = R3 = R4 Half bridge: R1 and R2 identical piezoresistors with R3 and R4 identical fixed resistors or vice versa What is the relation between a change in resistance ΔR and the output voltage eo? eo eo R1 R 3 R 2 R 4 R1 R4 e o R3 R4 R1 R 2 ei ei eo R1 R1 R2 R1 R 2 2 eo R2 R1 eo ei R2 eo R3 R1 R1 R 2 2 R3 R2 eo R4 R 4 higher order term s. R4 R 3 R 4 2 R3 R3 1 R1 R2 R4 4 R R R R R3 R 3 R 4 2 R4 Gage factors and the piezoresistive effect What is the relation between deformation and resistance? R Gage factor: F R R R R L L R A A higher order term s L R R R L L A A Metals Semiconductors Changes in geometry dominate Changes in resistivity dominate L R A R L L A R A R * Strain causes differences in atomic spacing, which in turn causes changes in band gaps and thus ρ. * Gage factors for strain gages Piezoresistors made of metals are usually used in strain gages responding to uniaxial strain. Te toca a ti Find the gage factor for a strain gage subject to uniaxial strain applied to an isotropic material. (Hint: you can neglect products of length changes; i.e., ΔhΔw ≈ 0.) F 1 2 Gage factors for semiconductors Recall that in semiconductors changes in resistivity dominate resistance changes upon deformation. Stress formulation: R R R R L L A A L L T T πL and πT and are the piezoresistance coefficients • L – longitudinal: in the direction of current • T – transverse: perpendicular to the direction of current Strain formulation: L L T T γL and γ T and are the elastoresistance coefficients Gage factors for semiconductors Te toca a ti Find the gage factor for a typical semiconductor device. Use the elastoresistance coefficients in your formulation. (Hints: Recall that in semiconductors changes in resistivity dominate resistance changes upon deformation. How will you model the stress/strain?) Gage factor: F R R R L R R R F L T F L L L T T L L T T T L T Most likely not isotropic Gage factor as figure of merit Gage factor is a figure of merit that • helps us decide which material to use for a piezoresistor • helps us decide where to put the piezoresistors Material Gage factor, F Metals 2-5 Cermets (Ceramic-metal mixtures) 5-50 Silicon and germanium 70-135 Physical placement and orientation of piezoresistors 1 2 3 eo ei 4 R3 1 R1 R2 R4 4 R R R R F R R L F 4 1 2 3 4 =≠ 00 ! Physical placement and orientation of piezoresistors eo ei F 4 1 2 3 4 The sensitivity will decrease. Device case study: Omega PX409 pressure transducer Device case study: Omega PX409 pressure transducer Some definitions Schematics of the sensor Piezoresistors detect stress and strain of the wafer using a bridge configuration. Electrical output signal is proportional to the inlet pressure. Designing for a given sensitivity We would like to design a pressure sensor with a 0–1 MPa (145 psi) span, 0–100 mV full scale output, a 10 VDC excitation, and p-Si piezoresistors. What is the sensitivity? η = FSO/Span = (100 – 0) mV/(1 – 0) MPa = 100 mV/MPa How do we design the senor to achieve this sensitivity? Location of piezoresistors Where should we place the piezoresistors on the diaphragm? σC – towards the center σB – along the boundary Typical values at max deflection: σC = 45.0 MPa, σB = 22.5 MPa εC = 152 × 10-6, εB = -17 × 10-6 i i i i eo ei F 4 1 2 3 4 Designing for a given sensitivity Next, let’s find the change in output voltage corresponding to resistors in these locations. eo ei 1F R1 R 2 R 3 R 4 1 2 3 4 44 R R R R R1 , 3 σC R σB L L T T = γL εC + γT εB = (120)(152×10-6) + (-54)(-17×10-6) Typical values of stress, strain, and elastoresistance coefficients: σC = 45.0 MPa, σB = 22.5 MPa εC = 152 × 10-6, εB = -17 × 10-6 γL = 120 <110> γT = -54 <110> = 19.1×10-3 Designing for a given sensitivity Te toca a ti Find the values of ΔR2/R and ΔR4/R using the same assumed values of stress, strain, and elastoresistance. R2,4 σC R L L T T = γL εB + γT εC σB = (120)(-17×10-6) + (-54)(152×10-6) Typical values of stress, strain, and elastoresistance coefficients: σC = 45.0 MPa, σB = 22.5 MPa εC = 152 × 10-6, εB = -17 × 10-6 γL = 120 <110> γT = -54 <110> = -10.2×10-3 Designing for a given sensitivity Requirements: • • • • 0–1 MPa (145 psi) span 0–100 mV full scale output 10 VDC excitation η = 100 mV/MPa η = FSO/Span eo ei 1 R1 R 2 R 3 R 4 4 R R R R 1 4 = (147 – 0) mV/(1 – 0) MPa 19 . 1 10 . 2 19 . 1 10 . 2 10 3 14 . 7 mV/V. With ei = 10 V e o 147 mV = 147 mV/MPa Need to attenuate the signal. Attenuation of output inverting amplifier KIA = -Rf/R0 Rf The gain is K = 100 mV/147 mV = 0.682 K = (KIA) (KIA) = (-Rf/R0)(-Rf/R0) = (Rf/R0)2 voltage signal from bridge Ro + Rf Ro + transducer output Te toca a ti Select two resistors (es decir, Rf y R0) from the available resistors below to achieve K = (Rf/R0)2 = 0.682. Readily-obtained resistors for use in an op-amp circuit (Ohms) 1 8.2 22 56 150 390 1.5 9.1 24 62 160 430 2.7 10 27 68 180 470 4.3 11 30 75 200 510 4.7 12 33 82 220 560 5.1 13 36 91 240 620 5.6 15 39 100 270 680 R0 6.2 16 43 110 300 750 6.8 18 47 120 330 820 7.5 20 51 130 360 910 Rf With Rf = 7.2 Ω and R0 = 6.2 Ω K = 0.683 Attenuation of output The amplifier goes into the signal conditioning compartment of the transducer voltage signal from bridge Ro Rf + Rf Ro + transducer output Te toca a ti A configuration of p-Si resistors on a square diaphragm is suggested in which two resistors in series are used to sense the maximum stress, σC, as shown in the figure. Find second resistor in series 1b 1a 3a 3b a. the new bridge equation (i.e., eo in terms of ei and the various resistances), b. ΔR/R for each resistor, c. Δeo/ei, and d. the transducer sensitivity (with no amplifier circuit) Assume the same dimensions, sensor requirements, materials, and stress/strain values as in the case study.