Project Contributions

advertisement

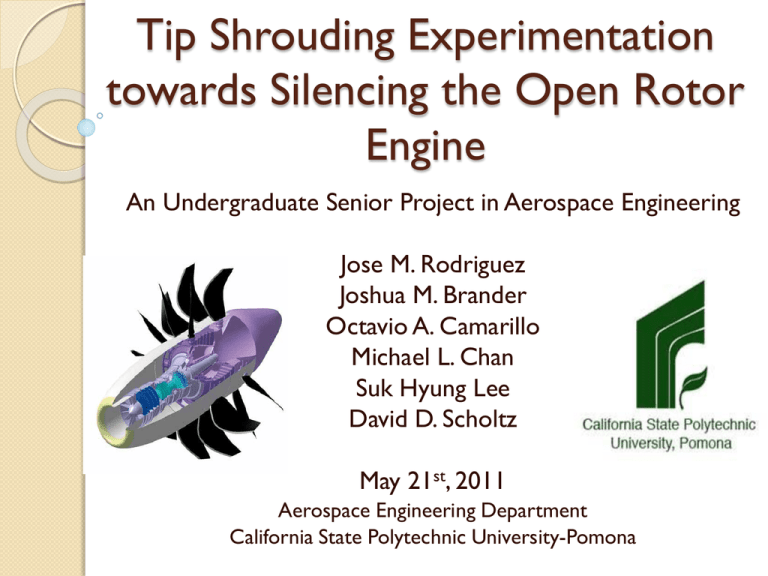

Tip Shrouding Experimentation towards Silencing the Open Rotor Engine An Undergraduate Senior Project in Aerospace Engineering Jose M. Rodriguez Joshua M. Brander Octavio A. Camarillo Michael L. Chan Suk Hyung Lee David D. Scholtz May 21st, 2011 Aerospace Engineering Department California State Polytechnic University-Pomona Introductions Joshua Brander Lucerne Valley, CA Background & Interests: Automotive Racing Model Rocketry Project Contributions: Aerodynamics CAD/Design Computational Fluid Dynamics 5/21/2011 Jose M. Rodriguez et. al 2 Introductions Octavio Camarillo Anaheim, CA Background & Interests: Aerodynamics Structural Dynamics Project Contributions: Structural Analysis 5/21/2011 Jose M. Rodriguez et. al 3 Introductions Michael Chan Garden Grove, CA Background & Interests: CNC Programming/Machining Manufacturing & QA. Unmanned Aerial Vehicles Project Contributions: Aerodynamic Design Testing & Manufacturing Configuration/Integration 5/21/2011 Jose M. Rodriguez et. al 4 Introductions Suk Hyung Lee Seoul, Republic of Korea Background & Interests: Military Service- Infantry (Korea) PCB Design & Electronics Mfg Distinguished Honors Student Sigma Gamma Tau Tau Beta Pi Alpha Gamma Sigma Golden Key Int’l Project Contributions: Rapid Prototype Manufacturing Finite Element Methods/Structural Analysis 5/21/2011 Jose M. Rodriguez et. al 5 Introductions David Scholtz Ontario, CA Background & Interests: Logistics/Cargo Planning Math & Physics Tutoring Project Contributions: CAD/Design Graphics & Modeling Acoustic Measurement 5/21/2011 Jose M. Rodriguez et. al 6 Introductions Jose M. Rodriguez Apple Valley, CA Background & Interests: Military Service– U.S. Navy Aircraft Maintenance Flight Test/Operations Air Breathing Engines Turbomachinery Project Contributions: Project Manager Integration & Testing Acoustic Measurement 5/21/2011 Jose M. Rodriguez et. al 7 History & Background Engines Commonly known as : ◦ Open Rotor ◦ “Propfans” ◦ Unducted Fan Engines Courtesy of NASA GRC External set of Counter-Rotating blades ◦ Power Turbine-driven ◦ Mechanically (gearbox) driven 5/21/2011 Jose M. Rodriguez et. al 8 History & Background Two Main Programs: ◦ GE/NASA ◦ UDF GE-36 1970’s-1989 Turbine Driven ◦ Pratt & Whitney-Allison ◦ UHB 578-DX 1986-1990 Gearbox Driven 5/21/2011 Jose M. Rodriguez et. al 9 History & Background Interest sparked in 1970’s due to rising fuel prices/Oil Embargos Promising designs showed a 30% improvement in Fuel Efficiency 5/21/2011 Jose M. Rodriguez et. al 10 History & Background Problems & Disadvantages: ◦ Limited Mounting Configurations ◦ High Vibrations imparted onto fuselage ◦ Reduced Cruising Speeds ◦ VERY LOUD!!!!! In-cabin noise said to be extreme despite aft mounting on MD-80 series testbed aircraft A reduction of approx. 30dB was needed to realize this concept 5/21/2011 Jose M. Rodriguez et. al 11 Why Study? Interest in Open Rotor Engines is making a comeback due to increasing fuel/oil prices and “Green” revolution ◦ GE/NASA Leap-X/CF34 ◦ Rolls-Royce RB2011 Pertinent & Interesting topic for senior project Multi-faceted study 5/21/2011 Jose M. Rodriguez et. al 12 Our Approach Attempt to silence by: ◦ Understanding & Manipulating Blade Tip Vortices Blade Vortex Interaction (BVI) Noise Turbulence Ingestion & Broadband Noise ◦ Use of a shroud to reduce BVI & Broadband Noise Minimize drag Maximize blade exposure to free stream Reduce Turbulent Wakefield 5/21/2011 Jose M. Rodriguez et. al 13 Our Approach Mimic known good/previous work GE/NASA (Allison) Rolls-Royce 5/21/2011 Jose M. Rodriguez et. al 14 Tip Shrouding Typical Fan shrouds encapsulate entire rotor ◦ Drag becomes very unfavorable at high speeds Tip Shroud: ◦ Leaves over 70% of blade open to free-stream ◦ Geometry creates much less drag than a conventional shroud 5/21/2011 Jose M. Rodriguez et. al 15 Tip Shrouding 5/21/2011 Jose M. Rodriguez et. al 16 Limitations Manufacturing/Materials/Cost ◦ Avoid Aerodynamic/Blade re-designs (Time) Simple Mechanisms ◦ Variable Pitch & control too complex ◦ Basic power/drive method Static Testing (ground conditions only) Computing Power 5/21/2011 Jose M. Rodriguez et. al 17 Model Design Desired to use GE UDF blade configuration with a variant of NASA SR-7 Blade ◦ 12 Blade Front, 10 Blade Rear ◦ Could not acquire appropriate airfoil data, etc. Found P&W patent (expired 1996): ◦ Provided airfoil coordinates and data for aerodynamically-correct modeling. 5/21/2011 Jose M. Rodriguez et. al 18 Design & CAD David D. Scholtz 5/21/2011 Jose M. Rodriguez et. al 19 Blade Modeling Based off of UTC Patent # 4,730,985 ◦ Provided: cross-sectional data coordinates & blade angles ◦ Excel was used to convert 2D coordinates into 3D and rotate cross-section by associated blade angle Used Solidworks® to model 5/21/2011 Jose M. Rodriguez et. al 20 Considerations in Blade Design (Fixed-Pitch) Blade angle changed to run in static conditions Decreased blade loading was desired ◦ Blade Angle (BA): Angle from Chord Line to Plane of Rotation ◦ BA was decreased from 75.86o by 41.86o to decrease b along blade ◦ Root BA = 34.00o; Tip BA = 12.18o 5/21/2011 Jose M. Rodriguez et. al 21 Blade Angle Configuration 5/21/2011 Jose M. Rodriguez et. al 22 Build Considerations of Blades Increased thickness of to allow scaling and manufacturability ◦ Each half of airfoil face increased by .34 in, full scale to provide a scaled down thickness of .05 in. at the tip for model strength. 5/21/2011 Jose M. Rodriguez et. al 23 Rotor Modeling Rotors were created on SolidWorks, via Circular Patterning feature. Front (CW): ◦ 10 blades ◦ 6.50 in. diameter Rear (CCW): ◦ 8 blades ◦ 5.71 in. diameter 5/21/2011 Jose M. Rodriguez et. al 24 Nacelles for Test Rig Front and rear nacelles designed to allow smooth flow across rotors. 5/21/2011 Jose M. Rodriguez et. al 25 Tip Shrouds Two models designed to experiment with Model 1: ◦ Basic circular shape, internally flat Suspected would not be beneficial due to flow separation along inner wall of an un-cambered surface 5/21/2011 Jose M. Rodriguez et. al 26 Tip Shrouds Model II: ◦ Created with airfoil cross-section to augment flow across tip-shroud interface 5/21/2011 Jose M. Rodriguez et. al 27 Computational Fluid Dynamics Joshua M. Brander 5/21/2011 Jose M. Rodriguez et. al 28 CFD of Counter-Rotating Rotors • CD-Adapco STAR-CCM+ • Desired to Model Front CW and Aft CCW Rotor Blades simultaneously • Counter-Rotating Assemblies have very complex flows • Limited Computing Power Available • Modeled Front Assembly only 5/21/2011 Jose M. Rodriguez et. al 29 Turbulence Modeling Flow Visualization ◦ Trimmer Mesh Model w/ Prism Layer Mesher ◦ 0.02 sec Time Step with 30 Inner Iterations/Step ◦ K-Omega Turbulence Model Pressure Distribution ◦ Polyhedral Mesh Model with Prism Layer Mesher ◦ Smaller Time Step Required Fine Mesh 5 x 10-6 Time Step w/ 20 Inner Iterations per Step ◦ K-Omega Turbulence Model 5/21/2011 Jose M. Rodriguez et. al 30 Front Rotor Flow Velocity M = 0.2 (ground operation/take-off conditions) 1000 RPM Clockwise (CW) Rotation 5/21/2011 Jose M. Rodriguez et. al 31 Pressure Distribution (Incoming Flow) 5/21/2011 Jose M. Rodriguez et. al 32 Pressure Distribution (Thrust Side) 5/21/2011 Jose M. Rodriguez et. al 33 Streamline Pattern @ 0.5 sec or 8 Rotations 5/21/2011 Jose M. Rodriguez et. al 34 Tip Vortex Visualization 5/21/2011 Jose M. Rodriguez et. al 35 Front Rotor w/ Flat Shroud Flow Velocity M = 0.7 1000 RPM Streamline @ 0.5 sec or 8 Rotations 5/21/2011 Jose M. Rodriguez et. al 36 Visualization of Secondary Flows & Separation Flow Velocity M = 0.2 1000 RPM Streamline @ 0.5 sec or 8 Rotations 5/21/2011 Jose M. Rodriguez et. al 37 Unfavorable Flow Separation @ Tips 5/21/2011 Jose M. Rodriguez et. al 38 Front Rotor w/ Augmented Shroud Flow Velocity M = 0.2 (ground operation/take-off conditions) 1000 RPM Clockwise (CW) Rotation 5/21/2011 Jose M. Rodriguez et. al 39 Pressure Distribution (Incoming Flow) 5/21/2011 Jose M. Rodriguez et. al 40 Pressure Distribution (Thrust Side) 5/21/2011 Jose M. Rodriguez et. al 41 Streamline Pattern @ 0.5 sec or 8 Rotations 5/21/2011 Jose M. Rodriguez et. al 42 Flow Remains Attached @ Tip-Shroud Interface 5/21/2011 Jose M. Rodriguez et. al 43 Structural Analysis Octavio A. Camarillo 5/21/2011 Jose M. Rodriguez et. al 44 Front Rotor Blade Loading Pressure distribution modeled from CFD results of full scale model Load magnitudes are percentages of full scale loading Divided into four areas of different load intensity 5/21/2011 Jose M. Rodriguez et.al 45 Material Strength 5/21/2011 Jose M. Rodriguez et.al 46 Front Rotor Blade Pre & Post processing using FEMAP Analysis using NEi NASTRAN Static Analysis Blade will fail at 73% of CFD load Max load of 9.5 psi 5/21/2011 Jose M. Rodriguez et.al 47 Rear Rotor Blade No CFD simulation Available Used pressure magnitude of the front blade’s downwash Assumed Distribution to be same as the front blade’s. Blade will fail at 36% of CFD load Max Press. of 7.5 psi 5/21/2011 Jose M. Rodriguez et.al 48 Shroud Shroud deformation analysis Interest is in shroud critical deformation Clearance must be kept between blade tips and shroud at all times Critical Load at 30 psi ◦ Deflection of 0.144 in 5/21/2011 Jose M. Rodriguez et.al 49 Rapid Prototype/Building Suk Hyung Lee 5/21/2011 Jose M. Rodriguez et. al 50 Rapid Prototyping OBJET® Rapid Prototype Machine ◦ Alaris 30 3-D Printer 16μ layering 600 DPI when building along X & Y axis 800 DPI when building up along Z axis* 5/21/2011 Jose M. Rodriguez et. al 51 Materials 5/21/2011 Jose M. Rodriguez et. al 52 Prototyping Software Object Studio ◦ Source Files STL files SLC files ◦ Multiple objects on build tray ◦ Positioning ◦ Configuring object &tray parameters ◦ Sending the file to Alaris 3-D printer 5/21/2011 Jose M. Rodriguez et. al 53 Front Rotor Assembly Manufacturing Time • 226 g Model Material ◦ Warm-up 20 min ◦ Production 11 hr 40 min ◦ TOTAL: 12 hours • 565 g Support Material 5/21/2011 Jose M. Rodriguez et. al 54 Rear Rotor Assembly Manufacturing Time ◦ Warm-up 20 min ◦ Production 9 hr 20 min ◦ TOTAL: 9 hr 40 min • 138 g Model Material • 319 g Support Material 5/21/2011 Jose M. Rodriguez et. al 55 Manufacturing of Test Rig Michael L. Chan 5/21/2011 Jose M. Rodriguez et. al 56 NASA Test Rig Inspiration 5/21/2011 Jose M. Rodriguez et. al 57 Test Rig Manufacturing 5/21/2011 Jose M. Rodriguez et. al 58 Dual Pylon Test Stand 5/21/2011 Jose M. Rodriguez et. al 59 Motor L – Bracket 5/21/2011 Jose M. Rodriguez et. al 60 Pylons 5/21/2011 Jose M. Rodriguez et. al 61 Final Assembly 5/21/2011 Jose M. Rodriguez et. al 62 Testing Methods Jose M. Rodriguez 5/21/2011 Jose M. Rodriguez et. al 63 Compare Noise Fields Acquire 360° noise characteristics & observe any noticeable changes 5/21/2011 Jose M. Rodriguez et. al 64 Static Testing 2- 3400kV 14.8 Vdc Electric Motors, 2 Ch. DC Power Supplies 2-Brushless Electronic Speed Controls Individually measure RPM Noise Measurements Polar Plotsfor both open & shrouded rotors 5/21/2011 Jose M. Rodriguez et. al 65 Work to Follow Noise Tests & Measurement ◦ ◦ ◦ ◦ Desired: multi-channel microphone arrays Actual: Blue® Omni-Directional Microphone Audacity 1.3 Beta Software PolarPlot v.3.2.7 Study RPM capability & variation Install Instrumentation on Test Rig ◦ RPM/Tachometers 5/21/2011 Jose M. Rodriguez et. al 66 THANK YOU!!! Comments Suggestions Questions (no hard ones) Advice 5/21/2011 Jose M. Rodriguez et. al 67