Control Charts

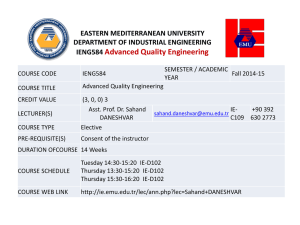

advertisement

Control Charts Using Minitab Control charts display the process average (center) and process variability (spread). Process Average is the “expectation” and Process Variability indicates “risk” associated with the expectation. Frequently Used Control Charts Attribute: Go/no-go Information, sample size of 50 to 100 p-chart (Proportion Defectives) c-chart (# Defects) u-chart (Defects/Unit) Variable: Continuous data, usually measured by the mean and standard deviation, sample size of 2 to 10 – X-bar and R-charts – X-bar and s-charts – X-charts for individuals 2 Attribute Charts in Minitab Stat / Control charts / Attribute Charts 3 p-Chart Hour SampSize Nonconforming 1 75 17 2 75 18 3 75 18 4 75 16 5 75 20 6 75 22 P C h art o f N o n c o n fo rm in g 0 .4 5 U C L = 0 .4 0 9 7 0 .4 0 P ro p o rt io n 0 .3 5 0 .3 0 _ P = 0 .2 5 8 1 0 .2 5 7 75 24 8 75 19 0 .2 0 9 75 15 0 .1 5 10 75 22 11 75 19 L C L = 0 .1 0 6 5 0 .1 0 1 3 5 7 9 11 13 15 17 19 21 23 25 S a m p le 12 75 24 13 75 12 14 75 22 15 75 20 16 75 20 P charts are used to study the proportion of defectives in each sample. A “defective” is an attribute that makes something useless. Data on non-conforming (defective) chips produced at a facility 4 c-Chart Unit SqFt Blemishes 1 66 2 2 66 2 6 3 66 0 5 4 66 0 5 66 1 6 66 4 7 66 0 8 66 0 9 66 2 C C h art o f B le m is h e s 1 S a m p le C o u n t 7 U C L = 6 .6 5 0 4 3 _ C = 2 .2 2 1 0 L C L= 0 1 6 11 16 21 26 31 36 41 46 S a m p le 10 66 3 Data are number of blemishes in 66sqft of painted area C charts are used to display the number of defects in each sample. A defect is a flaw that is undesirable but does not make the product useless. 5 U-Chart U C h art o f B le m is h e s 0 .1 2 1 SqFt Blemishes Rate 1 73 5 0.0685 2 70 4 0.0571 3 60 1 0.0167 4 57 1 0.0175 5 58 0 0.0000 6 57 3 0.0526 7 59 1 0.0169 8 52 4 0.0769 9 55 1 0.0182 10 59 2 0.0339 11 67 0 0.0000 12 55 2 0.0364 13 54 1 0.0185 U C L = 0 .1 0 1 7 0 .1 0 S a m p le C o u n t P e r U n it Unit 0 .0 8 0 .0 6 _ U = 0 .0 3 5 7 0 .0 4 0 .0 2 0 .0 0 LC L= 0 1 6 11 16 21 26 S a m p le 31 36 41 46 T ests p erfo rm ed w ith u n eq u al sam p le sizes Data are number of blemishes in different areas U charts are used to display the number of defects per unit of measurement. Useful when samples are of different sizes. 6 Variable Charts in Minitab Stat / Control charts / Variable Charts for Subgroups or Individuals 7 XBar-R Charts Sample Obs1 Obs2 Obs3 Obs4 Obs5 1 11.991 12.001 12.176 12.004 12.030 X-Bar charts are used to plot subgroup means. X b ar-R C h art o f O b s 1 , ..., O b s 5 12.2 3 4 12.065 11.946 12.011 12.018 11.980 12.069 12.223 12.089 12.065 11.955 S a m p le M e a n 2 12.125 12.155 U C L= 1 2 . 1 8 3 2 11.959 12.1 _ _ X= 1 2 . 0 4 5 7 12.111 12.0 12.197 LC L= 1 1 . 9 0 8 2 11.9 1 8 15 22 29 36 43 50 57 64 S a m p le 5 11.783 12.140 12.008 12.076 12.044 U C L= 0 . 5 0 4 1 6 11.962 12.132 12.149 S a m p le R a n g e 0.48 11.991 7 12.163 11.961 11.932 12.115 8 12.053 12.053 11.889 11.975 0.36 12.128 _ R = 0.2384 0.24 11.870 0.12 0.00 1 12.037 LC L= 0 8 15 22 29 36 43 50 57 64 S a m p le 9 12.108 11.942 12.102 11.967 Data represents actual contents in 12 oz soda cans 12.056 R charts are used to plot the range for each subgroup. 8 XBar-S Charts X-Bar charts are used to plot subgroup means. Sample Obs1 Obs2 Obs3 Obs4 Obs5 1 11.991 12.001 12.176 12.004 12.030 2 12.065 12.018 12.223 11.955 11.959 3 11.946 11.980 12.089 12.125 4 12.011 12.069 12.065 12.155 5 11.783 12.140 12.008 12.076 12.0 6 11.962 12.132 12.149 11.991 11.9 S charts are used to plot the standard deviation of each subgroup. X b ar-S C h art o f O b s 1 , ..., O b s 5 S a m p le M e a n 12.2 U C L= 1 2 . 1 8 3 2 12.111 12.1 12.197 _ _ X= 1 2 . 0 4 5 7 12.044 LC L= 1 1 . 9 0 8 2 12.128 1 8 15 22 29 36 43 50 57 64 S a m p le 7 12.163 11.961 11.932 12.115 8 12.053 12.053 11.889 11.975 11.870 9 12.108 11.942 12.102 S a m p le S t D e v 0.20 11.967 U C L= 0 . 2 0 1 3 12.037 0.15 _ S= 0 . 0 9 6 3 12.056 0.10 0.05 0.00 LC L= 0 1 8 15 22 29 36 43 50 57 64 S a m p le 9 Is the Process in Control? XBar-S Chart X (individual) Chart X b ar-S C h art o f O b s 1 , ..., O b s 5 I C h art o f S o d aC an s 12. 1 1 2 .3 __ X= 12. 0457 12. 0 1 2 .2 LC L= 11. 9082 11. 9 1 8 15 22 29 36 43 50 57 64 S a m p le 0. 20 S a m p le S t D e v 1 2 .4 UC L= 12. 1832 UC L= 0. 2013 0. 15 _ S= 0. 0963 0. 10 In d iv id u a l V a lu e S a m p le M e a n 12. 2 U B= 1 2 .2 1 2 .1 _ X= 1 2 .0 4 5 7 1 2 .0 1 1 .9 LB= 1 1 .9 1 1 .8 0. 05 1 1 1 .7 0. 00 LC L= 0 1 8 15 22 29 36 S a m p le 43 50 57 64 1 36 71 106 141 176 211 246 281 316 O b se rva tio n 10 Process Capability P ro c es s C ap ab ility o f S o d aC an s LS L USL P ro c e ss D at a 1 1 .9 LS L T arg e t * USL 1 2 .2 S am p le M e an 1 2 .0 4 5 7 S am p le N 350 S t D e v ( W it h in ) 0 .1 0 2 5 0 1 S t D e v ( O v e rall) 0 .1 0 3 5 2 8 W it h in O v e rall P o t e n t ial ( W it h in ) C ap ab ilit y Cp 0 .4 9 CP L 0 .4 7 CP U 0 .5 0 Cp k 0 .4 7 O v e rall Cap ab ilit y Pp 0 .4 8 PPL 0 .4 7 PPU 0 .5 0 Ppk 0 .4 7 Cp m 1 1 .8 1 1 .9 1 2 .0 1 2 .1 O b se rv e d P e rfo rm an c e E x p . W it h in P e rfo rm an c e P P M < LS L 7 4 2 8 5 .7 1 P P M < LS L 7 7 5 6 7 .8 6 P P M < LS L PPM > USL 7 7 1 4 2 .8 6 PPM > USL 6 6 1 3 7 .5 5 PPM > USL P P M T o t al 1 5 1 4 2 8 .5 7 P P M T o t al 1 4 3 7 0 5 .4 1 1 2 .2 * 1 2 .3 E x p . O v e rall P e rfo rm an c e P P M T o t al 7 9 6 3 6 .6 8 6 8 0 7 8 .2 0 1 4 7 7 1 4 .8 8 Process capability refers to the ability of a process to produce a defect-free product or service in a controlled manner of production or service environment 11