MS401-03-EOQ - Sabancı Üniversitesi

advertisement

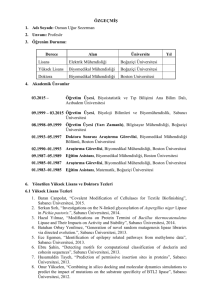

MS 401 Production and Service Systems Operations Spring 2009-2010 Inventory Control – I Deterministic Demand: EOQ Model Slide Set #3 Murat Kaya, Sabancı Üniversitesi 1 Office Hours • Ceyda Sol: Thursday 14:00-15:30 • Özlem Çoban: Wednesday 15:00-16:30 • Mahir Umman Yıldırım: Monday 14:30-16:00 • The assistants' office hours will be conducted at L068, unless announced otherwise • Murat Kaya: Tuesday 14:40-15:40, Thursday 13:40-14:40, Office: G020 Murat Kaya, Sabancı Üniversitesi 2 Whom to Email? The Coordinators • Each graduate assistant coordinates some aspect of the course. Please email the assistants on administrative issues before emailing the instructor (Dr. Kaya). Your questions should be directed as follows: • Assignment-related questions to CEYDA • Project-related questions to OZLEM • Recitation and Exam-related questions to MAHIR (including make-up exam issues) Murat Kaya, Sabancı Üniversitesi 3 Some Basic Definitions • An inventory is an accumulation of a commodity that will be used to satisfy some future demand. • Inventories may be of the following form: - raw material - components (subassemblies) - work-in-process - finished goods - spare parts - pipeline Murat Kaya, Sabancı Üniversitesi 4 Total Investment in Inventories in US (1999) Copyright © 2001 by The McGraw-Hill Companies, Inc Murat Kaya, Sabancı Üniversitesi 5 Motivation for Holding Inventories Murat Kaya, Sabancı Üniversitesi 6 Characteristics of Inventory Systems 1. Demand • • constant versus variable known versus uncertain 2. Replenishment lead time 3. Review • periodic or continuous 4. Replenishment • periodic or continuous 5. Excess demand – backordered or lost 5. Changing Inventory • perishability or obsolescence Murat Kaya, Sabancı Üniversitesi 7 Cost Structure • Order costs – fixed (Set-up cost, K) – variable, per-unit (c) • Holding costs (h) – – – – • Penalty cost (p) – if backordering allowed: loss of goodwill – if demand lost: loss of goodwill + loss of profit Murat Kaya, Sabancı Üniversitesi 8 Inventory Turnover Ratios for Different Industries Industry Upper quartile Median Lower quartile Electronic components and accessories 8.1 4.9 3.3 Electronic computers 22.7 7.0 2.7 Household audio and video equipment 6.3 3.9 2.5 Paper Mills 11.7 8.0 5.5 Industrial chemicals 14.1 6.4 4.2 Bakery products 39.7 23.0 12.6 Books: Publishing and printing 7.2 2.8 1.5 Murat Kaya, Sabancı Üniversitesi 9 The Economic Order Quantity (EOQ) Model Murat Kaya, Sabancı Üniversitesi 10 Assumptions Leading to EOQ • Demand rate, λ, is constant and deterministic over time (units/day, units/year, etc.) • Shortages not permitted • No replenishment lead time • The cost structure includes – fixed ordering cost, K, per order placed – unit variable cost, c, independent of order size (no discounts) – holding cost, h • Infinite planning horizon Murat Kaya, Sabancı Üniversitesi 11 Why EOQ ? • Easy to compute • Does not require data that is hard to obtain • Policies are surprisingly robust • Assumptions can be relaxed • Gives a good overall idea • Can be starting point for more complicated models Murat Kaya, Sabancı Üniversitesi 12 EOQ - Notation Recall the notation we introduced earlier: Q = order quantity (we want to find the optimal Q) K = fixed order cost c = unit variable cost, $ / unit h = holding cost, $ / (unit * (unit time)), λ = demand rate, units / (unit time) Murat Kaya, Sabancı Üniversitesi h= I c 13 The Objective • Our aim is to determine the best replenishment strategy (when and how much to order) under the criterion that the relevant costs (order and holding costs) will be minimized over time Murat Kaya, Sabancı Üniversitesi 14 EOQ Model - Intuition • “When” should we place a new order ? – – – – assume zero starting inventory demand is deterministic and at a constant rate lead time is negligible no backorders are allowed Murat Kaya, Sabancı Üniversitesi 15 EOQ Model - Intuition • “How much” we have to order each time ? – parameters do not change over time – there is no reason for ordering different quantities – so, order the same quantity Q in each order Murat Kaya, Sabancı Üniversitesi 16 Economic Order Quantity Model Decision Variable: Q, the order size Inventory Slope= -λ Q T Time 17 Murat Kaya, Sabancı Üniversitesi Deriving the EOQ: The “Cycle” • The same picture occurs over and over again – why? – any one of the triangles will be called a “cycle” • Why not minimize the total cost in a cycle? – • Minimize the average cost per unit time (annual cost) • Convert the order and holding costs to “average annual cost”, using the total cost in a cycle Costs per T units of time T otalcost in a cycle T T Cyclelength lim Murat Kaya, Sabancı Üniversitesi 18 Deriving the EOQ: The Order Cost • Cycle length T =Q / λ (slope, - λ, = -Q/T) • Since Q / λ is the time between two orders (the cycle time), λ /Q is the number of orders per unit time • In each order, we pay K+Qc • Order cost per unit time = Murat Kaya, Sabancı Üniversitesi 19 Deriving the EOQ: The Holding Cost • Holding cost per unit time = T Q 2 Q h Q t dt h holdingcost over one cycle Q 2 0 h Q Q cyclelength 2 T • This can also be calculated as Q hAverage inventory level h 2 Murat Kaya, Sabancı Üniversitesi 20 Deriving the EOQ G(Q) G' (Q) K Q2 h 2 G' ' (Q) 2 K Q h * Murat Kaya, Sabancı Üniversitesi 2 K 0 3 Q =Ic 21 The Average Annual Cost Curve cost unit time Annual fixed ordering and holding cost The minimum G(Q) hQ 2 K Q Q* Murat Kaya, Sabancı Üniversitesi Q 22 An Example • Suppose that you are working for a retail store and have to determine how many boxes of detergent to order. • Suppose every time you make an order you pay $20 for transportation and $10 to prepare the ordering request. • Suppose every dollar tied in the inventory would earn 10 cents annually, if you had invested it. • Suppose there is a regular weekly demand of 20 boxes and each box costs you $10. • What is the order quantity? • What is the trade-off here? Murat Kaya, Sabancı Üniversitesi 23 Solution • λ=20*52 = 1040 boxes annually • K (fixed ordering cost) = $30 each time • h (holding cost) • Q*= T: cycle length = Annual holding cost = Annual fixed ordering cost = Murat Kaya, Sabancı Üniversitesi 24 Inventory Turnover Ratio with EOQ Model • Turnover Ratio: A measure of effective inventory control – “how many times I sold my inventory?” demand rate 2h avg. inventory Qopt / 2 K Murat Kaya, Sabancı Üniversitesi 25 EOQ in a Production Environment • So far we have discussed a case in which we “order” from an outside supplier • If we produce in-house, the relevant problem is called the “Economic Production Quantity” • In this case, K denotes the “setup cost” • Why do we have a setup cost? Examples include: – cost of production setup independent of the number produced: heating an oven, cost of dyes etc – time required for the setup: lost production! – first few units might need to be scrapped Murat Kaya, Sabancı Üniversitesi 26