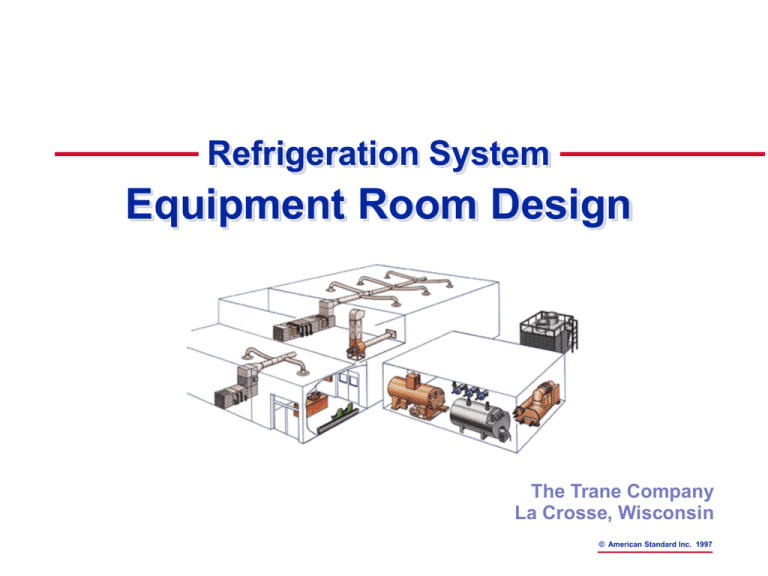

Refrigeration Sytem Equipment Room Design

advertisement

Refrigeration System Equipment Room Design The Trane Company La Crosse, Wisconsin © American Standard Inc. 1997 ANSI/ASHRAE Standards Standard 34-1992 … “Number Designation And Safety Classification Of Refrigerants” Standard 15-1994 … “Safety Code For Mechanical Refrigeration” © American Standard Inc. 1997 ANSI/ASHRAE Standards … Standard 34-1992 Purpose? To establish a … “… simple means of referring to common refrigerants instead of using the chemical name, formula, or trade name.” “… uniform system for assigning reference numbers and safety classifications to refrigerants.” “Number Designation And Safety Classification Of Refrigerants” © American Standard Inc. 1997 ASHRAE Standard 34-1992 … Refrigerant Safety Classifications higher flammability Group A3 Group B3 lower flammability Group A2 Group B2 no flame propagation Group A1 Group B1 lower toxicity higher toxicity © American Standard Inc. 1997 ASHRAE Standard 34-1992 … Refrigerant/Blend Data Refrig Qty Per Occupied Space Refrigerant Chemical Name Or Composition (% By Weight) Normal Boiling Point 75°F –22°F –41°F Safety Group A1 A1 A1 Lbs/ 1000 cu ft 1.6 12.0 9.4 PPM By Vol 4,000 40,000 42,000 Methane Series CFC (or R) –11 CFC (or R) –12 HCFC (or R) –22 Trichlorofluoromethane Dichlorodifluoromethane Chlorodifluoromethane Ethane Series CFC (or R) HCFC (or R) HFC (or R) HFC (or R) 1,1,2–Trichlorotrifluoroethane 2,2–Dichloro–1,1,1–Trifluoroethane 1,1,1,2–Tetrafluoroethane 1,1–Difluoroethane 118°F 81°F –15°F –13°F A1 B1 A1 A2 1.9 0.4 16.0 1.2 4,000 1,000 60,000 7,000 R–12 (73.8) / R–152a (26.2) R–22 (48.8) / R–115 (51.2) –27°F –49°F A1 A1 12.0 19.0 47,000 65,000 Azeotropes R–500 R–502 –113 –123 –134a –152a © American Standard Inc. 1997 ANSI/ASHRAE Standards … Standard 15-1994 Purpose? “… to specify safe design, construction, installation, and operation of refrigerating systems.” Scope? “This code established safeguards for life, limb, health, and property and prescribes safety standards.” “Safety Code For Mechanical Refrigeration” © American Standard Inc. 1997 ANSI/ASHRAE Standards … Standard 15-1994 It applies to … “ … mechanical refrigerating systems and heat pumps used in the occupancies defined in Section 4 and installed subsequently to adoption of this code” “Safety Code For Mechanical Refrigeration” © American Standard Inc. 1997 ANSI/ASHRAE Standards … Standard 15-1994 It also applies to … “… parts or components added after adoption of this code, or a change to a refrigerant of a different number designation after adoption of this code” “Safety Code For Mechanical Refrigeration” © American Standard Inc. 1997 ANSI/ASHRAE Standards … Standard 15-1994 Finally, it applies to … “… parts or components replaced after adoption of this code only if they are not identical in function” “Safety Code For Mechanical Refrigeration” © American Standard Inc. 1997 ANSI/ASHRAE Standards … Standard 15-1994 Provides classification criteria for … Safety group Occupancy type Refrigerating system “probability” “Safety Code For Mechanical Refrigeration” © American Standard Inc. 1997 ANSI/ASHRAE Standards … Standard 15-1994 Provides classification criteria for … Safety group Occupancy type Refrigerating system “probability” “Safety Code For Mechanical Refrigeration” © American Standard Inc. 1997 ASHRAE Standard 15-1994 … Safety Group Classification Standard 34’s refrigerant safety classifications higher flammability Group A3 Group B3 lower flammability Group A2 Group B2 no flame propagation Group A1 Group B1 lower toxicity higher toxicity © American Standard Inc. 1997 ANSI/ASHRAE Standards … Standard 15-1994 Provides classification criteria for … Safety group Occupancy type Refrigerating system “probability” “Safety Code For Mechanical Refrigeration” © American Standard Inc. 1997 ASHRAE Standard 15-1994 … Occupancy Classification Institutional Public assembly Where large numbers of occupants can’t vacate quickly Residential Occupants can’t readily leave without help Occupants have complete, independent living facilities Industrial Occupancy is restricted only to authorized personnel © American Standard Inc. 1997 ASHRAE Standard 15-1994 … Occupancy Classification Commercial Large mercantile Occupants transact business, receive personal services, or purchase food or other goods Premises where more than 100 people congregate to purchase personal merchandise Mixed Two or more occupancies share the same building © American Standard Inc. 1997 ANSI/ASHRAE Standards … Standard 15-1994 Provides classification criteria for … Safety group Occupancy type Refrigerating system “probability” “Safety Code For Mechanical Refrigeration” © American Standard Inc. 1997 ASHRAE Standard 15-1994 … Refrigerating System Probability System Designation High Probability Cooling Or Heating Source Air Or Substance To Be Cooled, Heated Direct Indirect Open Spray Double Indirect Open Spray Low Probability Indirect Closed Indirect Vented Closed © American Standard Inc. 1997 ASHRAE Standard 15-1994… Refrigerant Quantity Rules Applicable Rules By Occupancy Classification Refrigerant Group System Probability Institutional Public Assembly, Residential, Commercial, Large Mercantile A1 High Low 2 4 1 4 3 4 A2 High Low 5 7 5 7 3 7 A3 High Low 9 9 9 9 3 7 B1 High Low 2, 6 4 1, 6 4 3 4 B2 High Low 5, 6 7 5, 6 7 3 7 B3 High Low 9 9 9 9 3 7 Industrial © American Standard Inc. 1997 ASHRAE Standard 15-1994 … Refrigerant Quantity Rules Applicable Rules By Occupancy Classification Refrigerant Group System Probability Institutional Public Assembly, Residential, Commercial, Large Mercantile A1 High Low 2 4 1 4 3 4 A2 High Low 5 7 5 7 3 7 A3 High Low 9 9 9 9 3 7 B1 High Low 2, 6 4 1, 6 4 3 4 B2 High Low 5, 6 7 5, 6 7 3 7 B3 High Low 9 9 9 9 3 7 Industrial © American Standard Inc. 1997 ASHRAE Standard 15-1994 … Refrigerant Quantity Rules Rule 4 … “When the quantity of refrigerant in any system exceeds Table 1 amounts, all refrigerant-containing parts, except piping and those parts outside the building, shall be installed in a machinery room constructed in accordance with the provisions of 8.13.” © American Standard Inc. 1997 ASHRAE Standard 34-1992 … Refrigerant Safety Classifications Refrig Qty Per Occupied Space Refrigerant Chemical Name Or Composition (% By Weight) Normal Boiling Point 75°F –22°F –41°F Safety Group A1 A1 A1 lbs/ 1000 cu ft 1.6 12.0 9.4 PPM By Vol 4,000 40,000 42,000 Methane Series CFC (or R) –11 CFC (or R) –12 HCFC (or R) –22 Trichlorofluoromethane Dichlorodifluoromethane Chlorodifluoromethane Ethane Series CFC (or R) HCFC (or R) HFC (or R) HFC (or R) 1,1,2–Trichlorotrifluoroethane 2,2–Dichloro–1,1,1–Trifluoroethane 1,1,1,2–Tetrafluoroethane 1,1–Difluoroethane 118°F 81°F –15°F –13°F A1 B1 A1 A2 1.9 0.4 16.0 1.2 4,000 1,000 60,000 7,000 R–12 (73.8) / R–152a (26.2) R–22 (48.8) / R–115 (51.2) –27°F –49°F A1 A1 12.0 19.0 47,000 65,000 Azeotropes R–500 R–502 –113 –123 –134a –152a © American Standard Inc. 1997 Equipment Room Design Ventilation Refrigeration system placement Doors, passageways and access Refrigerant monitoring Open-flame devices Pressure-relief piping General requirements © American Standard Inc. 1997 Equipment Room Design Ventilation Refrigeration system placement Doors, passageways and access Refrigerant monitoring Open-flame devices Pressure-relief piping General requirements © American Standard Inc. 1997 equipment room design … Ventilation Volume requirements for … Natural ventilation Mechanical ventilation Normal rate Alarm rate © American Standard Inc. 1997 equipment room design … Ventilation Remote machinery room … Occupied Building More Than 20 Feet Occupied Building Refrigeration System Lean-to Or Other Structure With Natural Ventilation © American Standard Inc. 1997 equipment room design … Ventilation Natural ventilation For refrigerating systems installed “outdoors, more than 20 ft from [any] building openings …” F = G0.5 where: F = free opening area (sq ft) G = mass of refrigerant (lbs) © American Standard Inc. 1997 equipment room design … Ventilation Normal-rate mechanical ventilation Needed whenever the equipment room’s occupied Requirements: 0.5 cfm per sq ft OR 20 cfm per person Must operate, if necessary for operator comfort, at a volume that limits the temperature rise (T) to no more than 18°F © American Standard Inc. 1997 equipment room design … Ventilation Alarm-rate mechanical ventilation Required to exhaust accumulated refrigerant Q = 100 × G0.5 where: Q = airflow (cu ft per minute) G = mass of refrigerant (lbs) © American Standard Inc. 1997 equipment room design … Ventilation Suggested exhaust fan location … Exhaust Fan 6 Feet © American Standard Inc. 1997 equipment room design … Ventilation End View Exhaust Airflow Dual-purpose ventilation system … Plan View Ventilation Airflow © American Standard Inc. 1997 Equipment Room Design Ventilation Refrigeration system placement Doors, passageways and access Refrigerant monitoring Open-flame devices Pressure-relief piping General requirements © American Standard Inc. 1997 equipment room design … Refrigeration System Placement Unobstructed space for inspecting and servicing equipment Must comply with applicable safety standards and requirements of the presiding regulatory agency Clear head room not less than 7.25 ft below equipment over passageways © American Standard Inc. 1997 equipment room design … Refrigeration System Placement Multiple-chiller equipment room layouts … Refrigeration Systems Air Inlet Exhaust Fan Exhaust Fan Air Inlet Exhaust Fan Air Inlet Refrigeration Systems Arrangement A Refrigeration Systems Exhaust Fan Arrangement B © American Standard Inc. 1997 Equipment Room Design Ventilation Refrigeration system placement Doors, passageways and access Refrigerant monitoring Open-flame devices Pressure-relief piping General requirements © American Standard Inc. 1997 equipment room design … Doors, Passageways And Access Equipment room access limited to authorized personnel Adequate number and type of doors No openings to other parts of the building No “shared” air-handling systems © American Standard Inc. 1997 Equipment Room Design Ventilation Refrigeration system placement Doors, passageways and access Refrigerant monitoring Open-flame devices Pressure-relief piping General requirements © American Standard Inc. 1997 equipment room design … Refrigerant Monitoring “Detector” must … Be appropriately sensitive to the refrigerant(s) in use Activate alarm and ventilation at TLV®–TWA “Threshold Limit Value–Time Weighted Average” © American Standard Inc. 1997 equipment room design … Refrigerant Monitoring Sensor location and placement … Height: 18 inches above the floor Plan Continuous ventilation: Between the refrigeration system and room exhaust Intermittent ventilation: Close to the refrigeration system, between it and the room entrance © American Standard Inc. 1997 equipment room design … Refrigerant Monitoring Typical refrigerant monitor installation … Roof Or Concrete Floor Occupied Space Mechanical Equipment Room Refrigerant Monitor Sample-In Tubing 5 Feet Particle Filter 12–18 Inches Chiller © American Standard Inc. 1997 equipment room design … Refrigerant Monitoring Suggested sensor placement for intermittent ventilation … Refrigeration Systems Identifies refrigerant sampling points © American Standard Inc. 1997 equipment room design … Refrigerant Monitoring Typical multichannel scanner application … Refrigerant Monitor With Multichannel Option Pit Identifies refrigerant sampling points © American Standard Inc. 1997 Equipment Room Design Ventilation Refrigeration system placement Doors, passageways and access Refrigerant monitoring Open-flame devices Pressure-relief piping General requirements © American Standard Inc. 1997 equipment room design … Open-Flame Devices “No open flames that use combustion air from the machinery room shall be installed where any refrigerant is used.” Exceptions … Combustion air is ducted from outside and sealed to prevent refrigerant leakage into the combustion chamber A refrigerant detector is used to shut down combustion automatically if a refrigerant leak occurs © American Standard Inc. 1997 Equipment Room Design Ventilation Refrigeration system placement Doors, passageways and access Refrigerant monitoring Open-flame devices Pressure-relief piping General requirements © American Standard Inc. 1997 equipment room design … Pressure-Relief Piping Roof Suggested refrigerant vent piping … Support this pipe! (Alternate Arrangement) Exterior Wall Flexible Steel Connection Purge Discharge Vent Line Rupture Disc Assembly 15 Feet Above Ground Level Drip Leg (Length As Needed) 1/4” FL × 1/4” NPT Drain Valve © American Standard Inc. 1997 Equipment Room Design Ventilation Refrigeration system placement Doors, passageways and access Refrigerant monitoring Open-flame devices Pressure-relief piping General requirements © American Standard Inc. 1997 equipment room design … General Requirements Signs Changing, charging and storing refrigerants Self-contained breathing apparatus Two required per equipment room Emergency shutdown procedure General maintenance © American Standard Inc. 1997 ® An American-Standard Company