Material processing by electron beam

advertisement

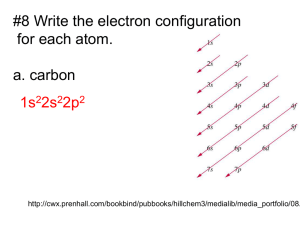

Slovak University of Technology Faculty of Material Science and Technology in Trnava Machine Tools And Devices For Special Technologies Electron beam machining Material processing by electron beam High intensity of electron beam energy (109 W/cm2), High speed of electrons (1,6 108 m/s), Small surface of impact (0,003 mm2), Electrons in the crash with particular atoms (molecules) of the base material transfer their energy. Depth of conjuction – depth in that electron transfer completely their energy. Material processing by electron beam Electrons are essentially bigger than photons. More often crashes of electrons with air molecules. Electron beam conductivity straight decreased with distance that must be overcome by beam in the air. There is used vacuum room that conductivity will be not decreased. Principle of machining by electron beam Kinetic energy transmission in the impact to thermal energy. In the short time (s) the small volume of material evaporated, steams are shoot out of becoming crater remainder of melting. Depth of conjunction is from some m to some tenths m. Principle of machining by electron beam Processing kinds by electron beam Cutting, micromachining, drilling, Marking, describing and engraving, welding, Thermal processing. Cutting by electron beam Relative movement between beam and workpiece is possible to securited: Moving of the workpiece on the compound desk – macromachining, trepanation of bigger holes, Deflection of electron beam by deflection reel micromachining. Electron lithography – engraving of mask on the workpiece surface before chemical processing (electronic component) Drilling by electron beam Small holes (5 m) with high accuracy (1m), Holes above 0,25 mm – beam tipping Bigger holes (above 2-5 mm) – trepanation accuracy 0,025 mm, They are used in production of filtre and riddles (big number of small holes). Fast production of accurately (dimensionally and positioning) holes. Drilling by electron beam number – 25600 diameter – 0,55mm material – anticorrosion steel Welding by electron beam Kinetic energy of impacted electrons is used for material melting, Possibility to chemical weld of active material in the vacuum room, Big depth of burnout, Minimum thermal influenced area, Needed continuous directing of beam energy from 0 to maximum Welding by electron beam Device scheme 1 – processing room, 2 – compound desk, 3 – workpiece, 4 – electron canon, 5a – cathode, 5b – anode, 6 - Wehnelt electrode, 7 – covering, 8 – focusing reel, 9 – deflecting reels, 10 – connecting to vacuum pump, 11 – electron beam, 12 – deflecting electron beam, 13 – input of high pressure Example of device Example of device Example of device