Maura

advertisement

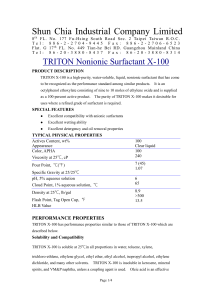

Rice Consortium •Methodology 1-Phase Behavior Salinity Maps for Optimal Blends 2-Static Adsorption Two-phase titration 3-Dynamic Emulsification/Demulsification Maura Puerto 4- 26-2011 1 Phase Behavior Methodology: High °C, Variable-hard brines Salinity Maps for Optimal Blends Best Blend : Foam, lowest possible IFT Injection Composition 4/13/2015 2 Mapping for Best Blend Selection 1. Triton X200 and IOS 20+ 0342………..90°C , 120°C 2. Avanel S70 and IOS 20+ 0342………. 90°C , 120°C 3. Avanel S150 and IOS 20+ 0342……… 90°C , 120°C The mapping is helping on the interpretation of coreflooding test results 4/13/2015 3 90°C Triton X200 100 IOS 0324 Seawater 100 90 80 70 60 50 40 30 20 10 0 0 Type I 90 10 Desirable 80 20 •Surfactant propagation • Foam formation 70 Bø 30 60 40 50 50 Type II Undesirable 40 30 60 70 20 80 10 90 0 100 0 10 20 30 40 50 60 70 Bø 80 90 100 Formation Water Test Sample 4 90°C Avanel S70 100 Bø IOS 0342 Sea Water 90 80 70 60 50 40 30 20 10 0 100 0 90 10 80 20 Bø 70 30 Dilution path 60 40 50 50 Type II 40 60 30 70 20 80 10 90 0 100 0 10 20 30 40 Formation Brine 50 60 70 80 90 100 5 120°C Sea Water Avanel S70 Bø 100 90 80 70 60 50 40 30 20 10 0 100 0 90 10 Type I 80 IOS 0342 20 70 30 60 40 50 50 40 60 30 70 Type II 20 80 10 90 0 100 0 10 20 30 40 50 Formation Brine 60 70 80 90 100 Bø Solubility Map of Blends Synthetic sea water (Ca , Mg) b-C16,17 - 9EO GS and IOS 20-24 IOS GS A suitable choice for injection in an EOR process is the 50/50 blend, 4/13/2015 7 Procedure _Static Adsorption Sample Preparation Blank (B) Test Sample (TS) •Weigh solution , ~ 20-25 cc, into two 40 cc vial •Weigh dolomite powder ~ 0.7-1.2 gram in TS •Insert stirrer in TS and condenser in B and TS •Immerse B &TS in 90°C oil bath •Let B and TS reach test temperature •Mix TS on a stirring plate for 10-15 sec •Return TS to bath Repeat for at least 3 times within 2 days •Let TS to equilibrate _Clear Supernatant_ •Titrate 3 aliquot of each supernatant •Plot Data •Calculate Concentration by Slope* Titrant conc. Titrant, ml 2.5 2 Oil Bath 1.5 1 0.5 2 mM 4 6 4/13/2015 8 2 mM 4 6 8 0 0 0.5 1 Sample, ml 1.5 2 2.5 8 REMARKS • Salinity Maps could be used for fast screening of surfactants for EOR process of variable sources of brine composition for injection and formation brines: • Reliable two, two-phase titration procedures developed for determining static adsorption at 90°C… •For mixtures of anionics: Epton’s (Methylene Blue) for Total (A1+A2) •For anionics+ soaps : Bromocresol for Total (A1+Asoap) and Epton’s for A1 •Rice developing HPLC Procedure for assesing adsorption of individual surfactant in mixture 4/13/2015 9 END 4/13/2015 10 Example of Selection of Optimal Blend, Bø Triton X-200_Enordet 0342 50/50:FB/SW S-Akal 90°C Triton X200 9/1 8/2 7/3 6/4 5/5 4/6 3/7 2/8 1/9 IOS 0342 Bø 4/13/2015 Set B Triton X-200_Enordet 0342 in 50_50 FB_SW and 1cc SLO 90°C .JPG 11 4/13/2015 12 Dynamic Emulsification/Demulsification Maura Puerto Tarek Hariz Chemical and Biomolecular Engineering 13 Objective • Develop apparatus for consistently testing Emulsification/Demulsification of crude oils One-pass Mini-Loop 14 One-Pass Emulsification Oil Pressure Transducer Card and Computer Pressure Transducer Brine CV Frit CV HPLC Pump Crude Oil/Emulsion 15 Example of One-pass emulsification 29% 3.5% NaCl / 71% crude oil Rate =7cc/min. Each sample collected ~2.5 minutes. Red line: volume of brine in samples At the top :. After Sample 6 collected Sample 1 has being aged for 15 minutes At the bottom: Samples after 96 hours of aging 16 Pressure Transducer Card and Computer Mini-Loop Pressure Transducer Demulsifier Brine Crude Oil/Emulsion Positive Displacement Pump 17 Effect of Shear 981 sec-1 685 sec-1 18 Emulsification-Demulsification Crude Oil Brine Injection Demulsifier Injected Emulsion with Demulsifier 65 cP 50/50 Water/Oil Emulsion 200 cP (NMR case) 4/13/2015 19 Percent Water Cut 4/13/2015 e = o e k k = 5.5 = water cut 20 Thanks For Coming Pemex Chevron 4/13/2015 21 Calculations • Calculating apparent viscosity from pressure drop measured • Hagen–Poiseuille equation 22 The Viscosity Of Crude -Oils Emulsions William Woelflin Drilling an Production Practice 1942 Page 152 ” ...the viscosity ratio ( temperature” Woelflin's correlation http://www.fortunecity.com/tatooine/falcon/502/emulflo2.html e / o ) for a given brine content is independent of e = o e k k = constant = water cut Many computer software for pipeline hydraulics calculation normally assume Woelflin's correlation for wet oil viscosity up to an inversion point which is usually assumed to be the same (typically 0.6) for all oils. The weakness of this approach lies in the following: •Woelflin's equation assumes total emulsification of the oil-water mixture which is far from the real situation in the pipe. The equation takes no account of the varying degrees of mixing in practice. •Wholesale pipes. application of the equation would lead to over -estimation of pressure loss in •It is inaccurate to assume that all oils have the same inversion water-cut. The error in equipment specification due to this assumption could be large, especially for water cuts close to the inversion point. Crude oils generally have differ. 4/13/2015 23 25 80 App. Viscosity centipoises Delta P psi 20 70 60 50 15 40 10 30 20 5 10 0 0 0 10 20 30 40 50 60 Minutes Emulsion Bottom 6.3X Hydrophobic Slide % Oil % Water Drop size Average m Top 63.2 36.8 34.8 Bottom 39.6 60.4 31.4 NMR values 4/13/2015 →18 24