Light Weight Fairway Mower FAB`s

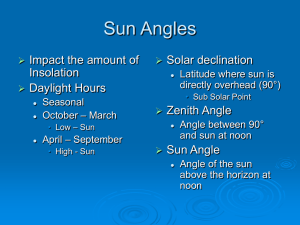

Reel Theory

John Deere

GOLF

& TURF

Training Department

(Left Click Selection Box)

Prism Gauge

Reel Cutting Unit

Clearance Necessary

.002” or .001”

Clearance

4. Top

Angle

Four Principle Angles

1. Relief

Angle

2. Rake

Angle

3. Front Angle

Reel Blade Relief Angle

.040”

(1 mm)

20 Degree

Relief Angle

Different Types of Relief

Ground

Relief

Milled

Relief

Reel Load Comparison

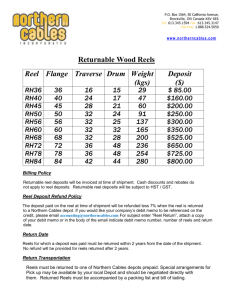

Reel-Bedknife Clearance

.002

” .005” Touch

Relief Ground / Sharp Bedknife (HP per unit) .75 .74 .88

No Relief / Sharp Bedknife (HP per unit) .87 .87 2.59

% Increase in HP Consumed ( per unit ) 16% 17.5% 294%

Increase in HP Consumed per 3235 (5 units) 0.6 hp 0.65 hp 8.55 hp

* Tests Conducted While Mowing 1.5” Bermuda to 1.0” HOC

Rake Angle

Rake Angle

Bedknife Angles

Top Angle

Top Angle 5 Degrees (6.5 Greens Mower)

Front Angle 5 Degrees

Front

Angle

Cutting Edges

Must Be Parallel

The Reel Must

Be Perfectly

Straight and the

Bedknife Must be Straight and

Flat in Order for

Them to Work

Properly

Reel

Bedknife

Cone Shaped Reel

Reels Can

Become Cone-

Shaped. This

Causes a Great

Deal of Strain on the Supporting

Bearings When

Adjusted Parallel to the Bedknife

Reel

Bedknife

Dull Edges

Edges Have

Become

Rounded…

No Longer a Sharp

Edge

Backlapping

Backlapping

Compound with Reel

Turning in

Reverse

Direction

Cutting Unit Dulling Curve

Sharp

Optimum

Cutting

Quality

Usable

Cutting

Quality

Dull

Elapse Time in Hours

Backlapping Retains

Optimum Cutting Quality

Sharp

Optimum

Cutting

Quality

Usable

Cutting

Quality

Dull

Elapse Time in Hours

Height of Cut (HOC)

Two Methods of Measuring HOC

Bench Setting

The Height at Which the Bedknife is Set Above a Firm Level Surface

Effective Cutting Height

The Actual Height at Which Grasses Are Cut

Bench Setting

Distance Between

Top of Bedknife and Bottom of

Rollers

Effective Height of Cut

Weight of the Cutting Unit and Attachments

Every 10 lbs results in .005” height difference

Soil Conditions

Roller Shape and

Surface Area

Grass Type

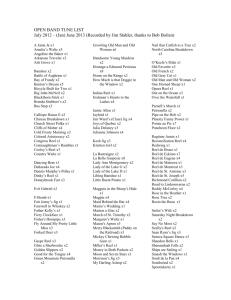

Frequency Of Cut (FOC)

Distance Traveled Between

Consecutive Cuts

Direction of Travel

FOC Factors

Number of Blades on Reel

Reel Speed (RPM)

Travel Speed

FOC Negative Effects

FOC Too Slow (Higher Number)

Marcelling (Wash Boarding)

(Rippled Effect)

FOC Too Fast (Lower Number)

Over Stressed Grass

Stripes and/or Brown Tips

Accelerated Component Wear

Marcelling

Wash-boarding

Rippling

Objectionable

Cut Quality

FOC “Guideline”

The Lower the Height of Cut (HOC)

The More Blades That Are Required

The Higher the HOC

The Less Blades That Are Required

Bedknife Attitude

Down

Level

Better Cut Quality

Better Stripe

Reduces Scuffing

Accurate Height of Cut Adjustment

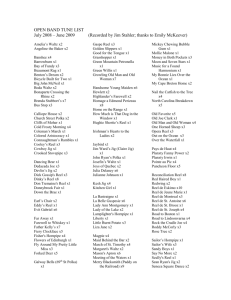

Reel / Bedknife Relationship

ESP Cutting Unit

(Parallel Bedknife)

.78 MM

11.76 MM

48

Reel / Bedknife Relationship

ESP Cutting Unit

(Bedknife Angled Down 6MM)

1.02 MM

13.43 MM

51

All Greases Are NOT

Created Equal

Bushing and

Shaft

Different Applications Require Greases with Characteristics that Meet Their Requirements