GRAVITROL - OKStatic

advertisement

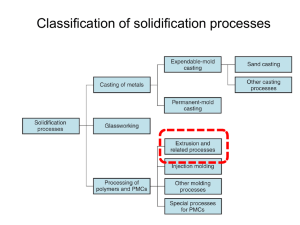

® GRAVITROL Extrusion Control Closed control loop: GRAVITROL® By the loss in weight in the weigh hopper over a time interval GRAVITROL ® measures the extruder output. The GRAVITROL® computer and the extruder drive module ensures that the extruder‘s output is always equal to the debit. 2 computer … … computer 3 Applications: • • • • • • Blown film extrusion Cast film extrusion Sheet extrusion Cable extrusion Profile extrusion … All extrusion processes which allow to measure the extruder‘s throughput gravimetrically (flow fed extruders) 4 Parameters, that cause problems without gravimetric extrusion control: • • • • • • • • • • Tolerances due to screw and barrel wear Changes in screen pack condition Changes of temperature Varying extruder power Polymer density Bulk density Melt temperature Polymer viscosity Different conditioned polymer Change in blend reciepe • Different line speeds 5 This is GRAVITROL® able to do : • Conversion of an extruder into a gravimetric metering element with exactly defined mass throughput (accuracy of ± 0,5% ) • Ensures exact layer ratios • Simplifies ramping up and down a line • Smooth changeover from manual to automatic • Synchronizes the extruder with the haul-off (also while ramping up and down a line) with an accuracy of ± 0,5%. Ensures product quality and economic operation GRAVITROL® is like „cruise control“ for extruders 6 Processes and product variables that can be controlled with GRAVITROL®: 7 Increase in profit with GRAVITROL® by: • Reduced labor costs and reduction of human-made errors • Automatic ramping up and down a line results in o Processes optimised in time o Final product is always in specification • Use of material can be adjusted very close to the minimum tolerances • Reduction of waste • The system learns the extruder‘s ramping curve by its own (normally this takes labor and time and errors can be made) • Can be used instead of a melt pump (much more expensive); except in fiber processes 8 GRAVITROL® : typical application Production of high energy cables: 9 GRAVITROL® : typical application Blown film extrusion 10 Ramping up and down a line: Typical extruder throughput curve not linear m’ 0 Extruder speed in % 100 11 Ramping up and down a line Extruder speed When ramping up a line for the first time the system learns the extruder curve by creating a step ramp. The evaluated function will be saved to the GRAVITROL® computer memory and is base for the exact control of the extruder output. time 12 Throughput control with GRAVITROL®: GRAVITROL® adjusts the extruder speed in a way that the throughput is always equal to the debit. m‘ [kg/h] Extruder speed [min-1] time 13 Components of a GRAVITROL® system EXB GRAVITROL® Computer Features and function: • 32-Bit Mikrocomputer (contains all necessary control algorithms for an accurate extrusion control) • Operator panel (for the operating personnel) with user-friendly surface 14 Components of a GRAVITROL® system HGB weigh hopper Features and function: • different hopper sizes for throughput up to 2.000 kg/h • High resolution load cell (resolution 1:1.000.000 • DSP (Digital Signal Processor) weigh module • material drain valve and door (depending on the model) • loading platform for vacuum reciever or swing gate • steep wall hopper for regrind material available 15 Components of a GRAVITROL® system The function of the HGB weigh hopper can be replaced by either: • a continuous gravimetric blender with weigh downcomer or • a GUARDIAN ® gravimetric batch blender with HGCweigh hopper 16 Components of a GRAVITROL® system features and functions: • 2 inputs for encoders • 8 outputs for: 1 EXL + max. 7 EXD or max. 8 EXD • connection to Mini-Op via ethernet port. 17 Example: GRAVITROL® system • Mono-extrusion • output control only • for the use of raw material (i. e. PE, PP, …) or pre-blend EXB GRAVITROL® Computer Material conveyance HGB weigh hopper EXD Extruder 18 Example: GRAVITROL® system • Mono-extrusion • output control and haul-off control • for the use of raw material (i. e. PE, PP, …) or pre-blend EXB GRAVITROL® Computer Material conveyance HGB weigh hopper EXD Extruder EXL Line speed module 19 Example: GRAVITROL® system • Co-extrusion with 3 extruders • output-, layer- and haul-off control • using X-series continuous gravimetric blenders Material conveyance X-series continuous gravimetric blender EXB GRAVITROL® Computer EXD Extruder EXD Extruder EXD Extruder EXL Line speed module 20 Example: simplified GRAVITROL® system with a GUARDIAN® blender and a HGC weigh hopper* • Mono-extrusion • output control • Installation follows the haul-off speed • use of a GUARDIAN® blender and a HGC weigh hopper EXB GRAVITROL® Computer *: This GRAVITROL® system represents a simplified low-cost solution which is often chosen in lines using gravimetric batch blenders. The haul-off has to be controlled manually by the operator. The GRAVITROL® system takes care of the correct extruder throughput referring to the current line speed. The system always follows the line speed. GUARDIAN® gravimetric charge blender HGC weigh hopper for GUARDIAN® Customer supplied haul-off control +/(or manual operation control) EXD Extruder EXLOX Line speed encoder 21 Data recording for preparing a quotation: In this data sheet all necessary data concerning throughput and extrusion process are caught 22